Non-excavation leaking inspection well repairing method and repairing structure

A repair method and inspection well technology, which are used in the repair of infrastructure, underwater structures, infrastructure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

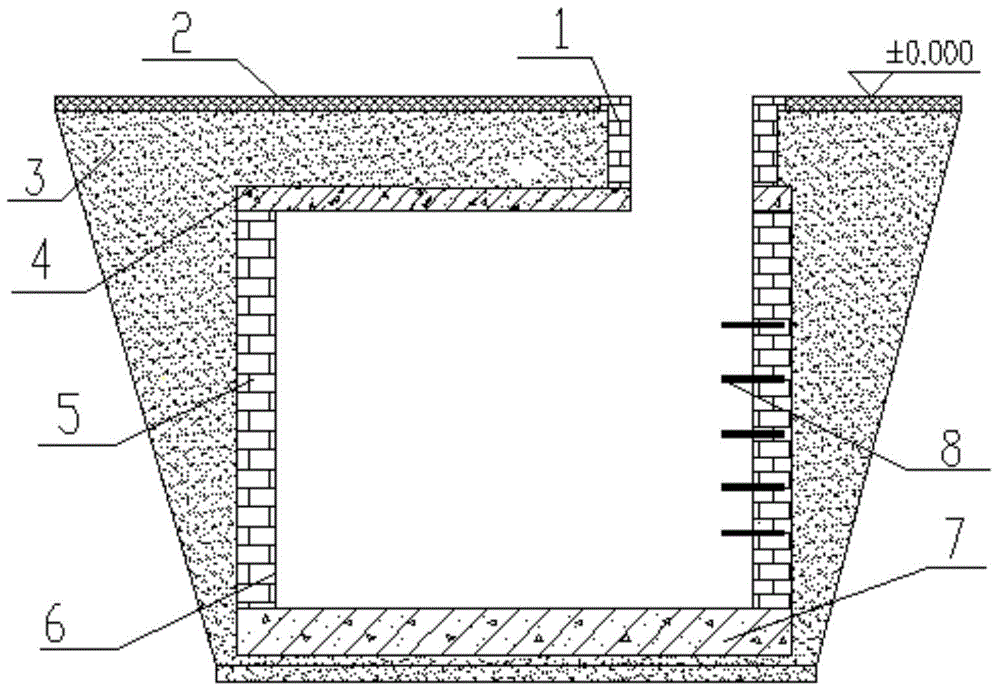

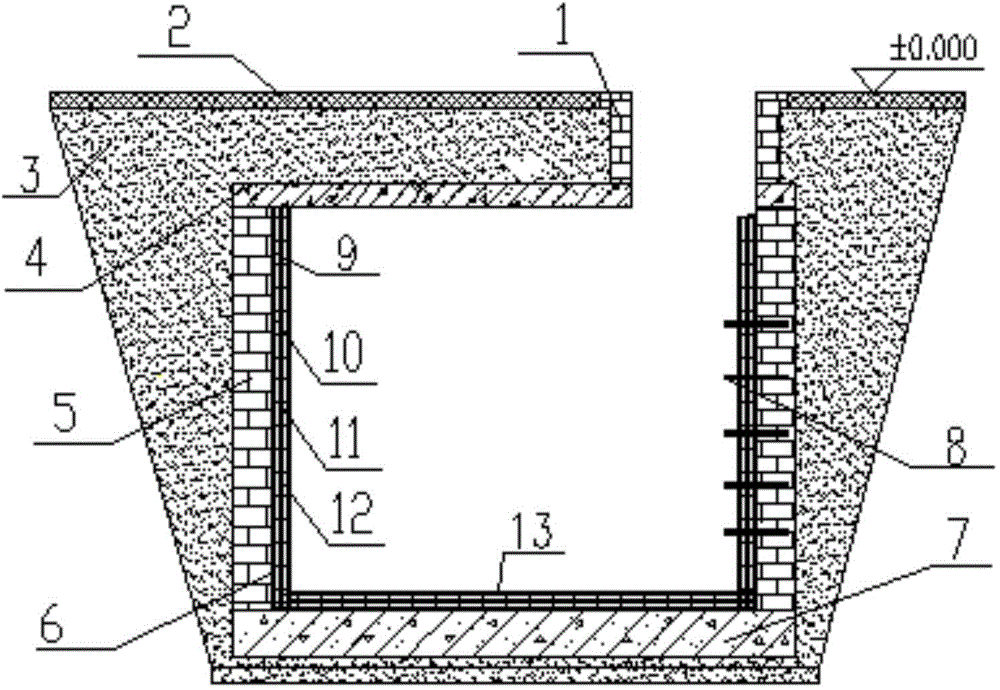

[0023] The advantages of the non-excavation internal repair technology for leakage inspection wells will be further explained below in conjunction with the description of the trenchless repair technology of the present invention with reference to the accompanying drawings and embodiments.

[0024] A non-excavation leakage inspection well repair method proposed by the present invention, such as figure 2 shown, including the following steps:

[0025] 1) After leakage occurs in the conventional inspection well, first drain the accumulated water in the inspection well, and check the location of the leakage (no need to excavate the inspection well);

[0026] 2) Use a quick-setting anti-seepage concrete plugging agent (product name: Quick Plugging King, GRT-TL007)9 on the inner wall of the inspection well to make a plugging layer to block the water leakage point; specific construction: use a dry cloth to seal the well wall After the base surface is dry, quickly apply the first lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com