Exhaust manifold device and front end cover processing method

A technology of exhaust manifold and front end cover, which is applied in the direction of exhaust device, muffler device, metal processing equipment, etc. It can solve the problems of cylinder exhaust turbulence, reduce exhaust resistance, improve utilization rate and service life, The effect of improving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

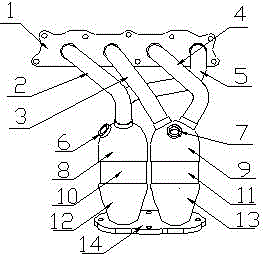

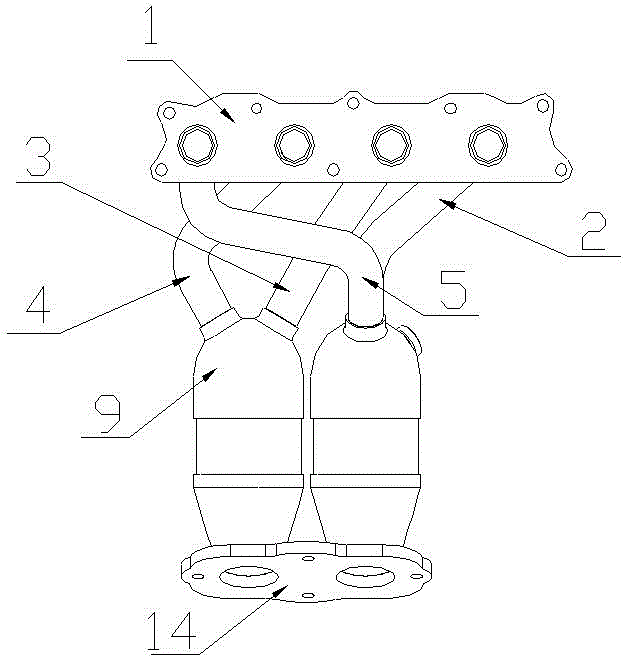

[0021] The exhaust manifold device adopted in this embodiment includes an inlet flange 1, an outlet flange 14 and an elbow exhaust channel connected with the cylinder fixed between the two, including the first elbow air channel 2, the second The elbow air channel 3, the third elbow air channel 4 and the fourth elbow air channel 5, the first catalytic converter front end cover 8, the first catalytic converter body 10 and the first catalytic converter rear end cover sequentially connected together 12, the second catalytic converter assembly is composed of the second catalytic converter front end cover 9, the second catalytic converter body 11 and the second catalytic converter rear end cover 13 which are sequentially connected together. Wherein, the elbow exhaust ports are connected together in groups of two according to the firing sequence of the cylinders at intervals, for example, the first elbow air port 2 and the fourth elbow air port 5 are connected together to form the fir...

Embodiment 2

[0025] A method for processing the front end cover of an exhaust manifold, processing the front end cover, comprising the following steps:

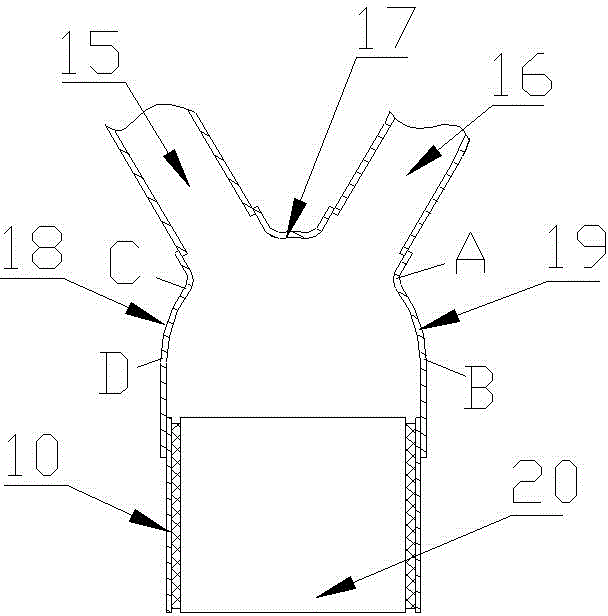

[0026] Step 1: Use Pro / Engineer software or CATIA v5 to establish a 3D model of the front cover, including the first air inlet, the second air inlet, the first drainage part at the connection between the first air inlet and the second air inlet, and The second arc-shaped drain connected to the first air inlet, the third arc-shaped drain connected to the third arc-shaped drain, and the front end cover body connected to the second arc-shaped drain and the third arc-shaped drain. In this embodiment, it is assumed that the initial arc radii of the second arc-shaped drain portion CD and the third arc-shaped drain portion AB are the same as the radius of the catalytic converter body, both being 50 mm. Users can set according to their needs.

[0027] Step 2: Use fluid mechanics to calculate the fluid distribution on the front surface of the cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com