Magnetic-nanoparticle-modification-based enzyme sensor used for detecting okadaic acid and preparation method of sensor

A technology of magnetic nanoparticles and okadaic acid, which is applied in the field of analysis and detection, can solve the problems of inability to realize online, real-time rapid detection, and low stability of PP2A enzyme, and achieve intuitive detection results, high detection structure accuracy, and short detection cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

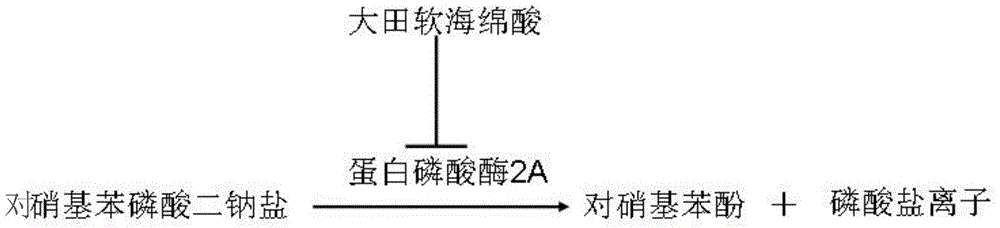

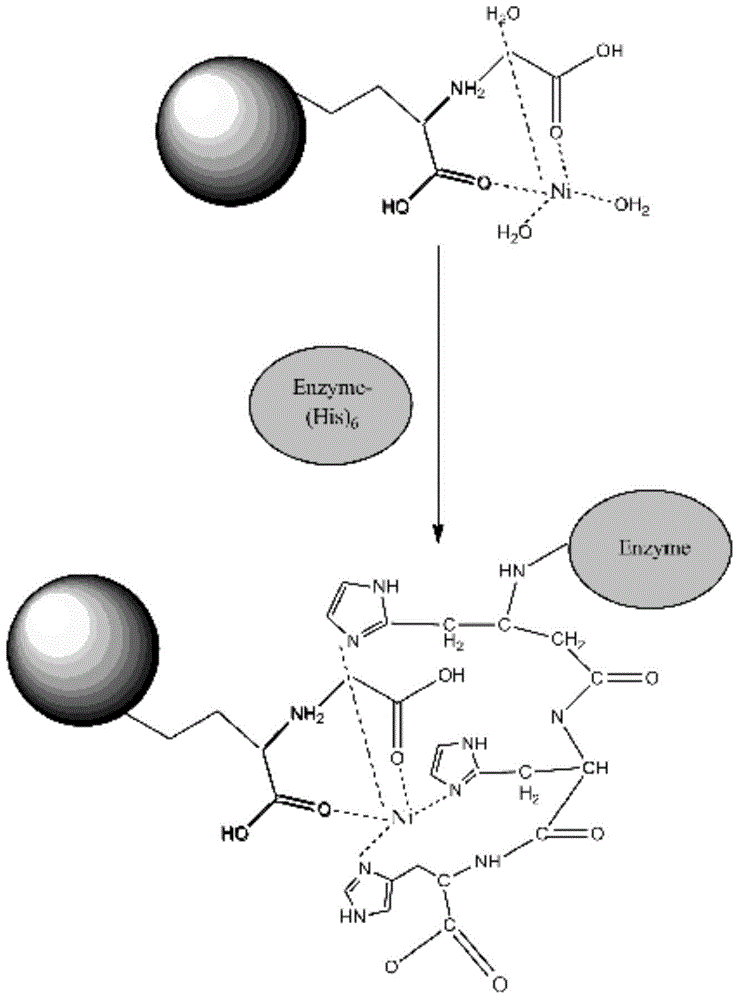

[0034] Add 30ul of Ni-IDA magnetic nanoparticle colloidal suspension with a diameter of 300nm into a microtube pre-filled with 300ul of binding buffer, mix well, and place the microtube on a magnetic stand (Adem Mag SV magnetic support, France ) to remove the liquid in the microtube, thus completing the cleaning of the magnetic nanoparticles. Repeat the cleaning once according to the above steps to fully remove non-specific binding, wherein the binding buffer is 20mM Tris solution with pH 7.5, solution Contains 500mM NaCl and 0.09% sodium azide.

[0035] After the Ni-IDA magnetic nanoparticles are fully washed, add 0.5ml of 1 unit / ul PP2A enzyme solution into the microtube, and shake the microtube at a speed of 800 rpm for 15min to make the magnetic nanoparticle colloidal suspension and the gene The engineered PP2A enzyme is fully coupled and adsorbed. After the reaction, the microtube is placed on the magnetic stand to remove the solution, and the magnetic nanoparticle-modifi...

Embodiment 2

[0038] Add 15ul of Ni-IDA magnetic nanoparticle colloidal suspension with a diameter of 300nm into a microtube pre-filled with 150ul of binding buffer, mix well, place the microtube on a magnetic stand to remove the liquid in the microtube, In this way, the cleaning of the magnetic nanoparticles is completed. Repeat the cleaning once according to the above steps to fully remove non-specific binding, wherein the binding buffer is 20mM Tris solution with pH 7.5, and the solution contains 500mM NaCl and 0.09% sodium azide.

[0039] After the Ni-IDA magnetic nanoparticles are fully washed, add 0.45ml of 1 unit / ul PP2A enzyme solution into the microtube, and shake the microtube at a speed of 750 rpm for 18min to make the magnetic nanoparticle colloidal suspension and the gene The engineered PP2A enzyme is fully coupled and adsorbed. After the reaction, the microtube is placed on the magnetic stand to remove the solution, and the magnetic nanoparticle-modified PP2A enzyme is obtained...

Embodiment 3

[0042] Add 20ul of Ni-IDA magnetic nanoparticle colloidal suspension with a diameter of 350nm into a microtube pre-filled with 200ul of binding buffer, mix well, place the microtube on a magnetic stand to remove the liquid in the microtube, In this way, the cleaning of the magnetic nanoparticles is completed. Repeat the cleaning once according to the above steps to fully remove non-specific binding, wherein the binding buffer is 20mM Tris solution with pH 7.5, and the solution contains 500mM NaCl and 0.09% sodium azide.

[0043] After the Ni-IDA magnetic nanoparticles are fully washed, add 0.6ml of 2 units / ul PP2A enzyme solution into the microtube, and shake the microtube at 850 rpm for 20 minutes to make the magnetic nanoparticle colloidal suspension and the gene The engineered PP2A enzyme is fully coupled and adsorbed. After the reaction, the microtube is placed on the magnetic stand to remove the solution, and the magnetic nanoparticle-modified PP2A enzyme is obtained. Was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com