Intelligent control device and control method of guide plate of combined harvester

A combine harvester and intelligent control technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of seeing the intelligent deflector of the threshing and separation device, the inability to operate in real time, and the low degree of intelligence. The effect of improving operation performance and intelligence, increasing automation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

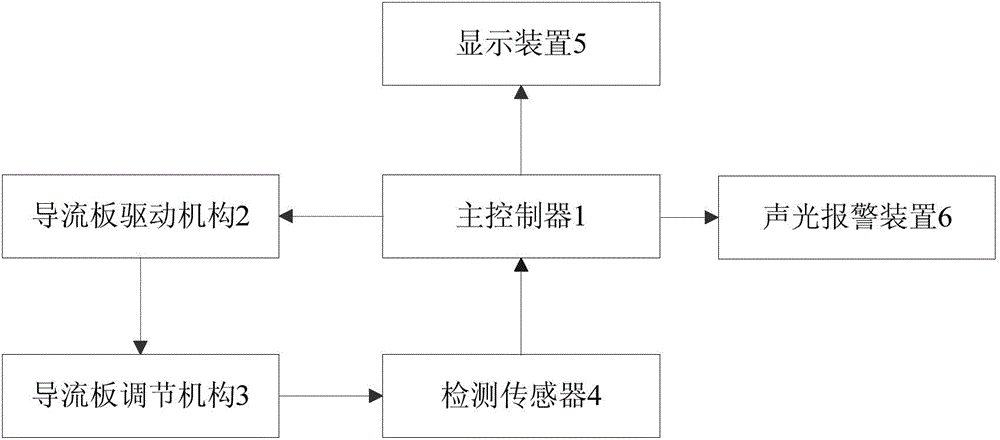

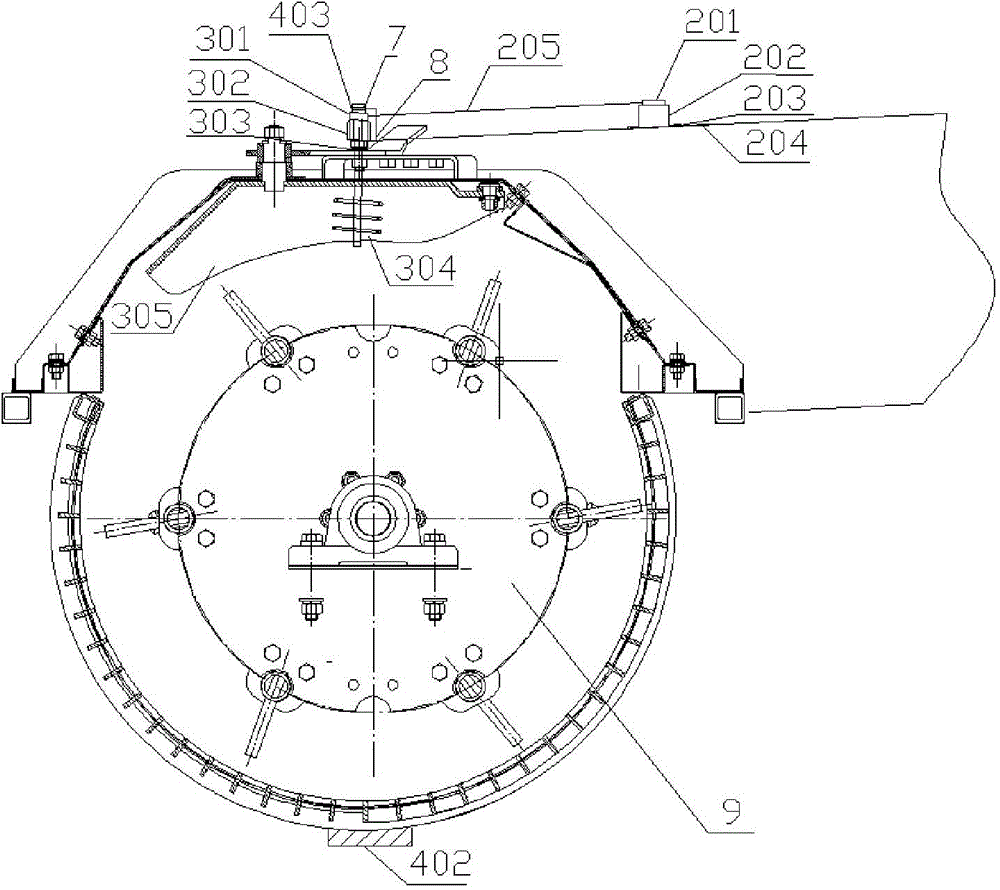

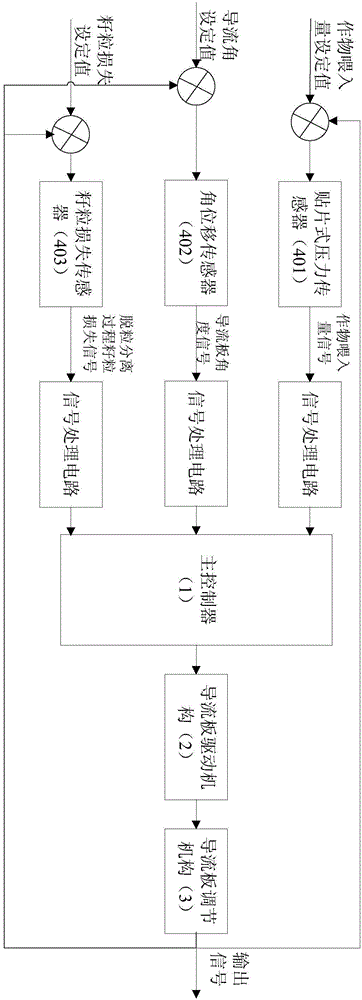

[0022] Combine harvester deflector intelligent control device, including main controller 1, deflector drive mechanism 2, deflector adjustment mechanism 3, detection sensor 4, display device 5, sound and light alarm device 6, angular displacement sensor clamp 7 , hoop fixing rod 8 and threshing cylinder 9.

[0023] Such as figure 1 As shown, the main controller 1 is respectively connected with the deflector driving mechanism 2, the deflector adjusting mechanism 3, the detection sensor 4, the display device 5 and the sound and light alarm device 6; the deflector adjusting mechanism 3 is connected with the deflector driving mechanism 2 are connected, and the deflector driving mechanism 2 is fixed on the top cover of the threshing drum; the main controller 1 and the display device 7 are installed in the cab of the harvester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com