Wood charcoal kiln smoke gas treatment system

A charcoal kiln and flue gas technology, which is applied in the charcoal kiln flue gas treatment system and charcoal kiln flue gas treatment system field, can solve the problems of difficult flue gas treatment and environmental pollution, and achieve low maintenance costs, no secondary pollution, The effect of protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

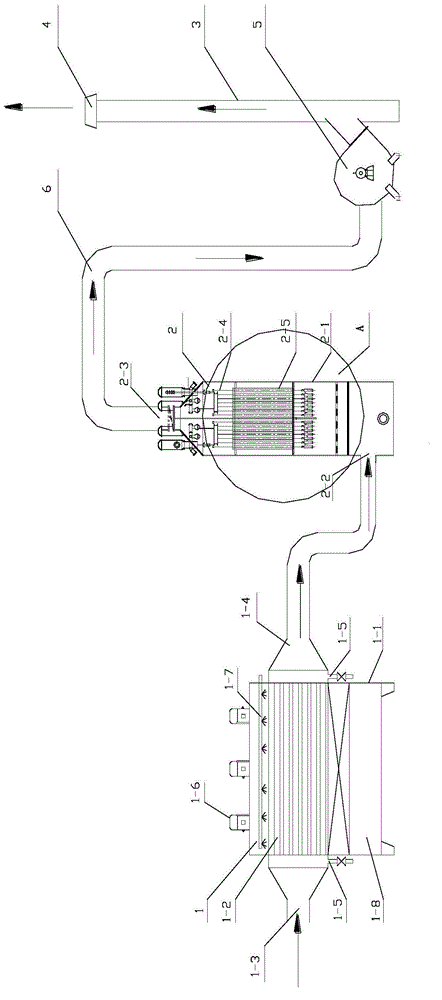

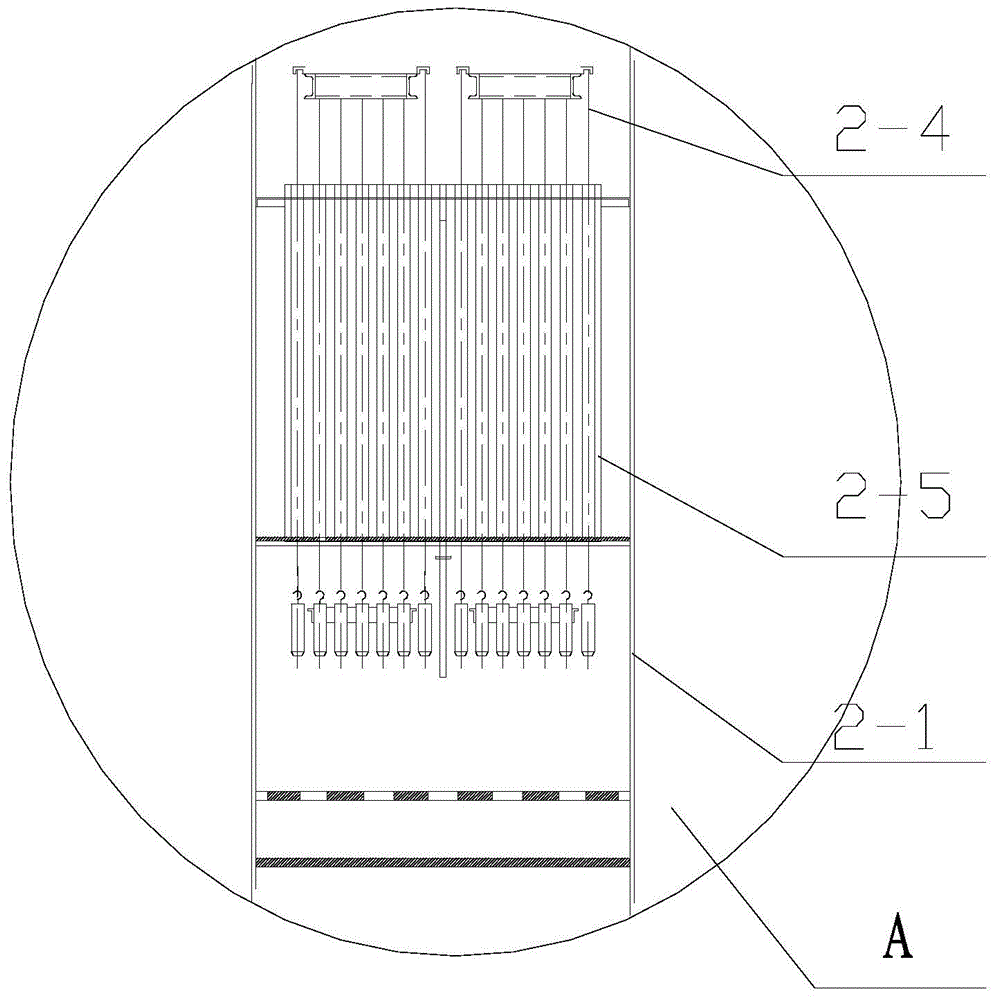

[0044] In order to solve the technical problem that the flue gas produced by the charcoal kiln is difficult to handle and pollute the environment in the prior art, the present invention invents a charcoal kiln flue gas treatment system, which has the advantages of simple operation, low energy consumption, environmental protection, and can thoroughly purify the flue gas The characteristics of the present invention will be further described below in conjunction with specific embodiments.

[0045] In the present invention, the power supply of the charcoal kiln flue gas treatment system is provided by the power distribution cabinet, and the power distribution cabinet is composed of the distribution box and the start and stop buttons installed on the control panel of the distribution box and the high-voltage DC power supply installed in the distribution box , oxygen sensor controller, air-cooling device contactor, water-cooling device contactor and oxygen sensor installed on the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com