A device for continuous discharge crushing ore and a method for crushing ore

An ore and high-voltage discharge technology, applied in grain processing and other directions, can solve the problems of not easy to control the crushed particle size, and the operation cannot be continuous, so as to improve the efficiency of electric crushing, overcome the existence of dead ends, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

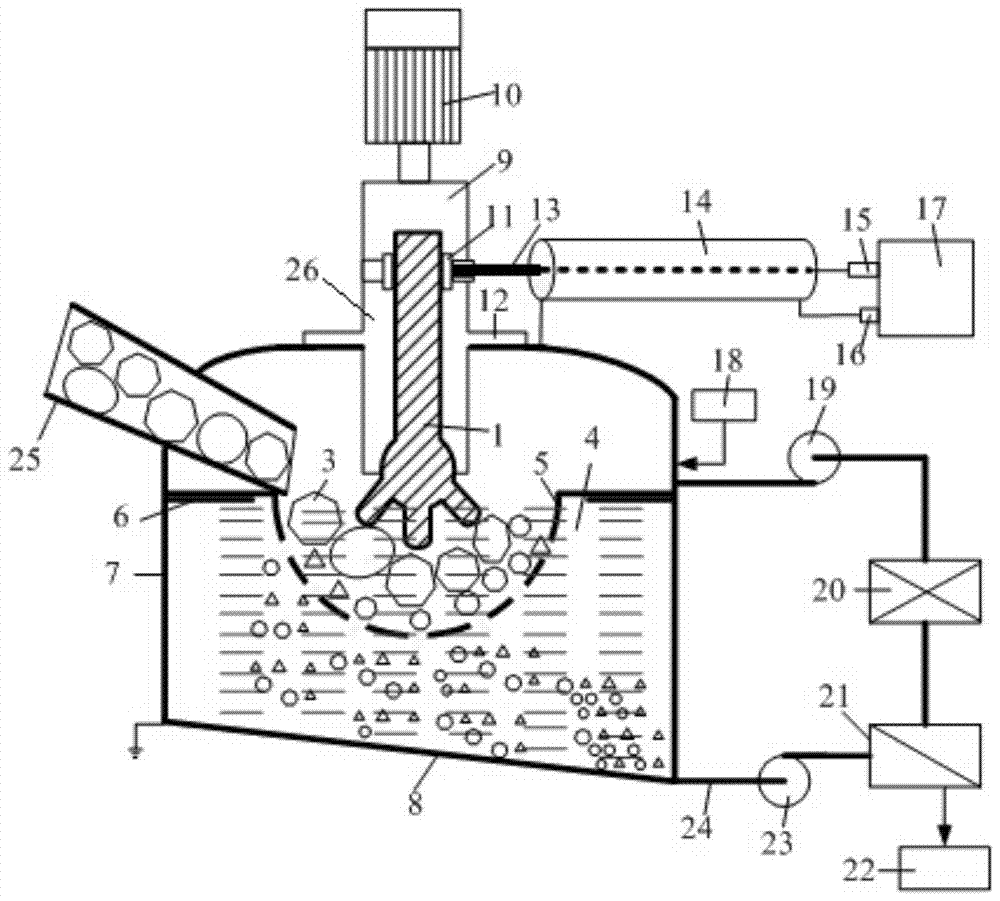

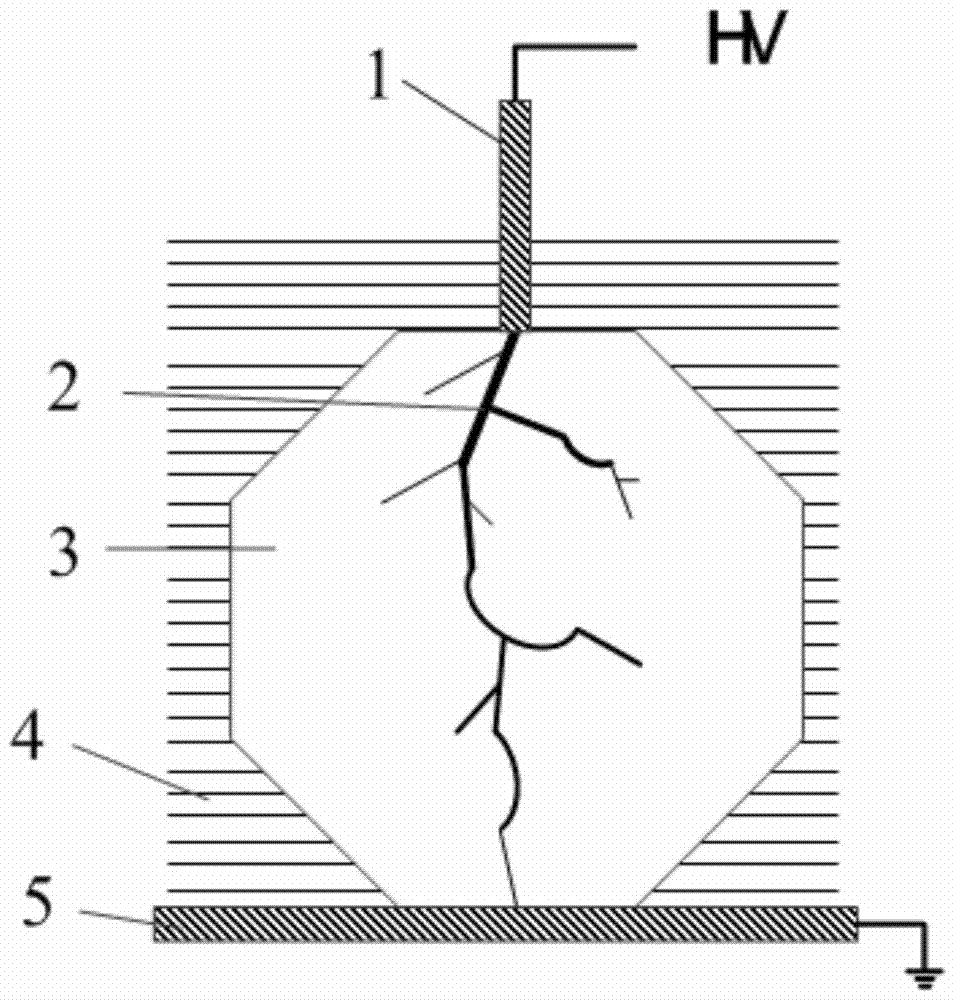

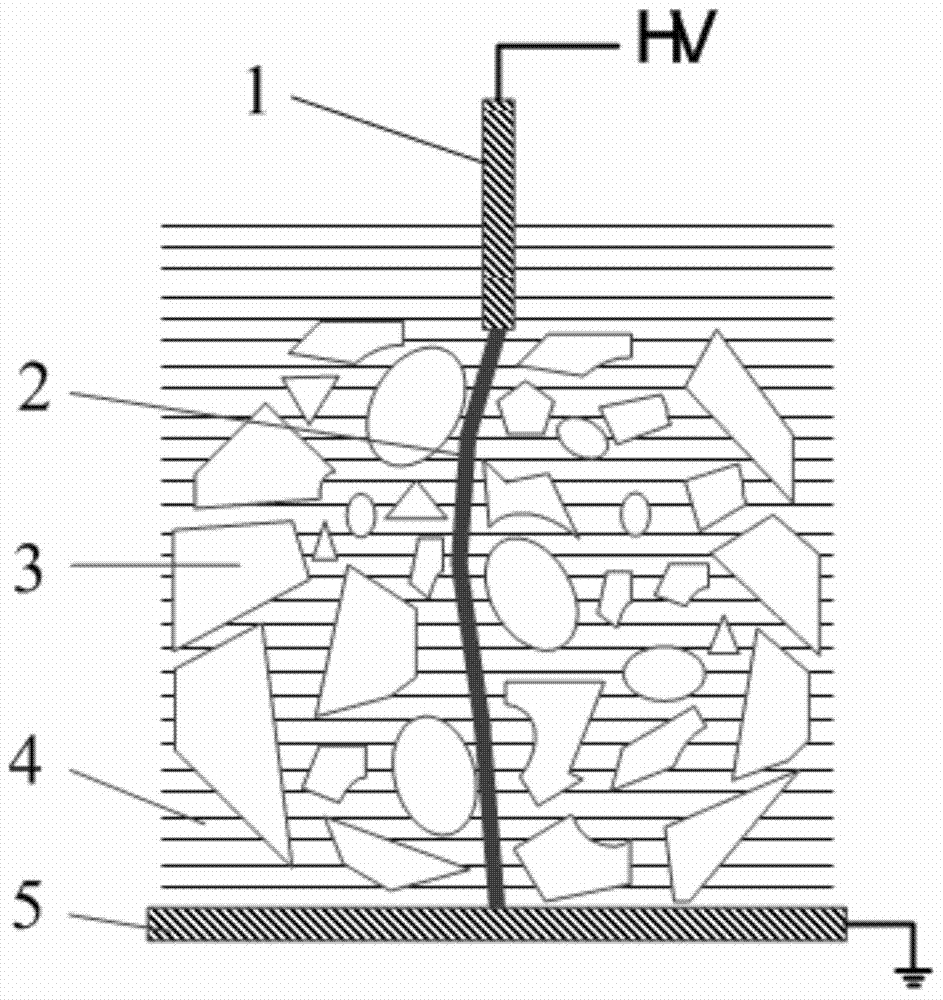

[0021] Embodiment 1, in conjunction with attached Figure 1-4 ,

[0022] A device for continuously discharging ore crushing, comprising a high-voltage pulse power supply 17, a high-voltage discharge electrode 1, a pulse transmission line 14, a low-voltage discharge electrode 5, a deionized water container 7, a mineral liquid separation device 21, a water circulation processing unit 20, and a motor 10 , the high-voltage discharge electrode 1 partially extends into the deionized water container 7, and an insulating sleeve 26 is arranged between the two. The deionized water container 7 is equipped with deionized water 4, and the middle part of the deionized water container 7 is fixed. The low-voltage discharge electrode 5, the low-voltage The discharge electrode 5 is provided with a cavity, and the bottom surface of the cavity is provided with a screen hole, and the high-voltage discharge electrode 1 extends into the cavity on the low-voltage discharge electrode 5, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com