Practical wire cutting water tank

A water tank and molding line technology, applied in the field of numerical control equipment, can solve the problems of poor filtration performance, increased resistance value of working fluid, easy to increase production cost, etc., and achieve the effects of convenient use and maintenance, quality assurance, and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

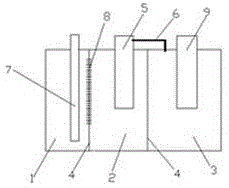

[0018] figure 1 It is a structural schematic diagram of a practical wire cutting water tank according to an embodiment of the present invention; the water tank includes three cavities from the water inlet pipe to the water outlet pipe: a coarse filter chamber 1, a fine filter chamber 2 and a clean chamber 3, and the coarse filter chamber 1 and The partition plate 4 structure between the fine filter chamber 2 can make the inside of the two chambers conduct. The partition 4 plate structure between the fine filter chamber 2 and the pure chamber 3 completely separates the two cavities, and the two cavities pass through the fine filter chamber 2. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com