Modification method of oleophylic and hydrophobic nano-sponge

A nano-cotton and hydrophobic technology is applied in the field of preparation of modified nano-cotton oil-absorbing materials, which can solve the problems of high cost, complicated operation, lack of oil-water selectivity, etc., and achieves improved oil absorption, simple operation, and improved reusability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare a toluene solution of propyltrichlorosilane with a concentration of 5.0%, soak the nano cotton in the above solution, make it fully absorbed and soak for 5 minutes, take out the sponge and squeeze it dry, fully dry it in a high-temperature drying oven, take it out, and use trichlorosilane Wash with methane three times, squeeze dry, and dry in a vacuum oven until constant weight.

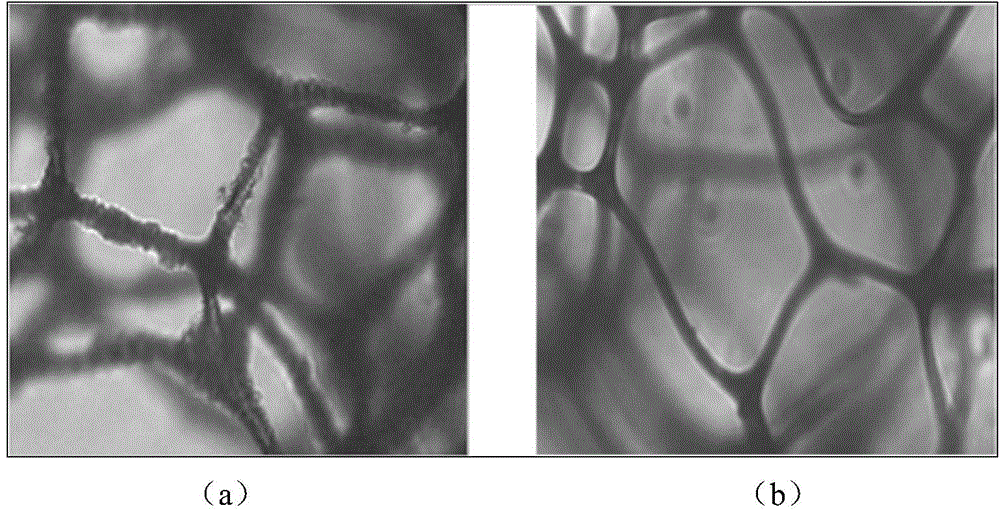

[0031] from figure 1 In (a), it can be seen that there is an uneven polysiloxane layer on the network structure skeleton of the sponge. The polysiloxane layer is very thin, which improves the oil-water selectivity while retaining the porosity of the nano-cotton; (b) shows the unmodified nano-cotton, showing a porous network structure.

Embodiment 2

[0033] Prepare an ether solution of trimethylchlorosilane with a concentration of 0.5%, soak the nano cotton in the above solution, make it fully absorbed and soak for 20 minutes, take out the sponge and squeeze it dry, fully dry it in a high-temperature drying oven, take it out, and wash it with ethanol 3 times, squeeze dry, and place in a vacuum oven to dry to constant weight.

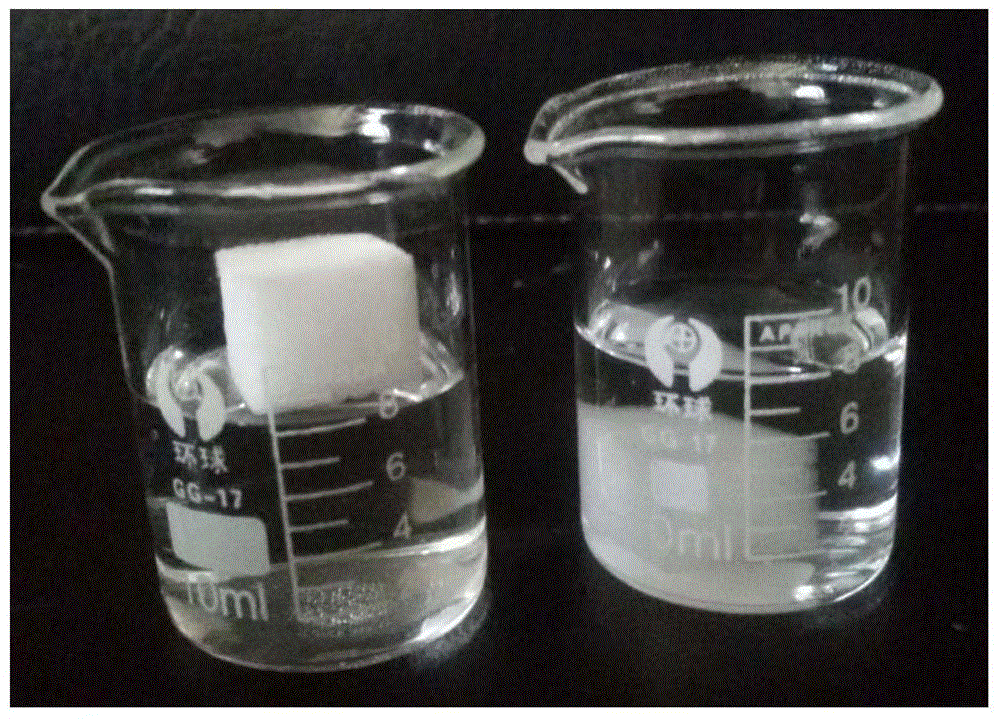

[0034] figure 2 Two white cubes in the middle beaker, the left is the modified nano-cotton, and the right is the unmodified nano-cotton. After immersing them in the same volume of water, the unmodified nano-cotton quickly and completely sank to the bottom of the water, and the modified nano-cotton could float on the water surface for a long time, indicating that its hydrophobicity has been significantly improved.

Embodiment 3

[0036] Prepare a n-hexane solution of dimethyldichlorosilane with a concentration of 0.1%, soak the nano cotton in the above solution, make it fully absorbed and soak for 10 minutes, take out the sponge and squeeze it dry, fully dry it in a high-temperature drying oven, take it out, and use Washed with petroleum ether 4 times, squeezed dry, and dried in a vacuum oven until constant weight.

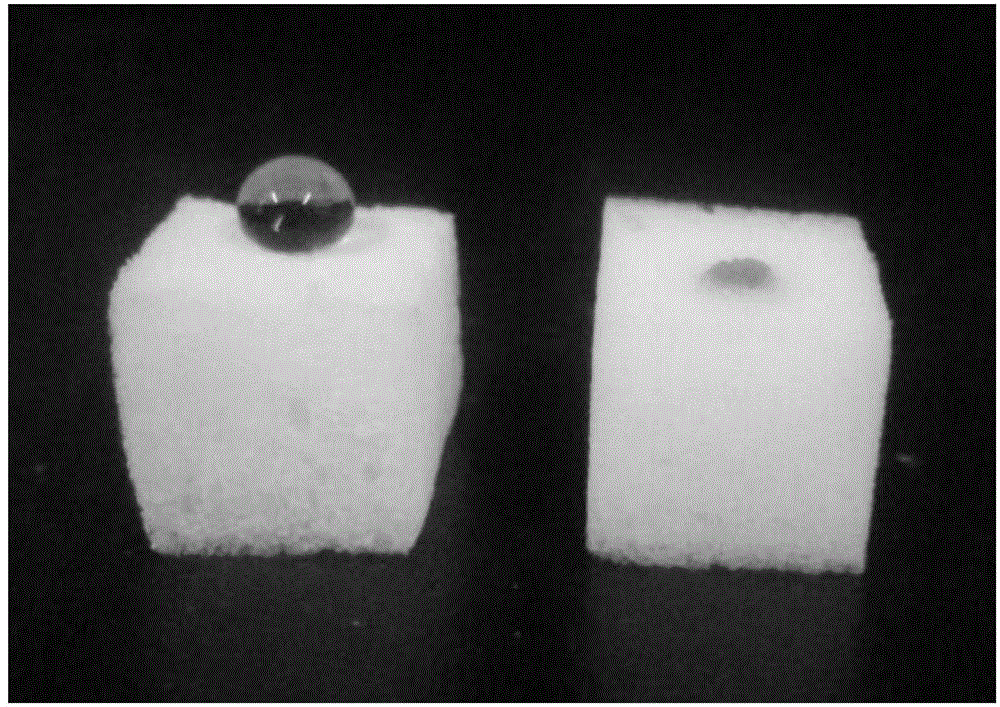

[0037] image 3 There are two white cubes in the middle, the modified nano-cotton on the left and the unmodified nano-cotton on the right. Drop a drop of water dyed blue by the ink on the surface of the nano-cotton, the water drop on the surface of the modified nano-cotton can maintain a spherical shape, and it does not change much after 10 minutes, while the water droplet on the unmodified nano-cotton is sucked into the nano-cotton disappear quickly. Compared with the unmodified nano-cotton, the hydrophobicity of the modified nano-cotton has been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com