Ion source maintenance device and ion source maintenance method

A technology for maintaining device and ion source, applied in ion implantation plating, coating, metal material coating process and other directions, can solve problems such as affecting experimental results, target pollution, wasting time, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

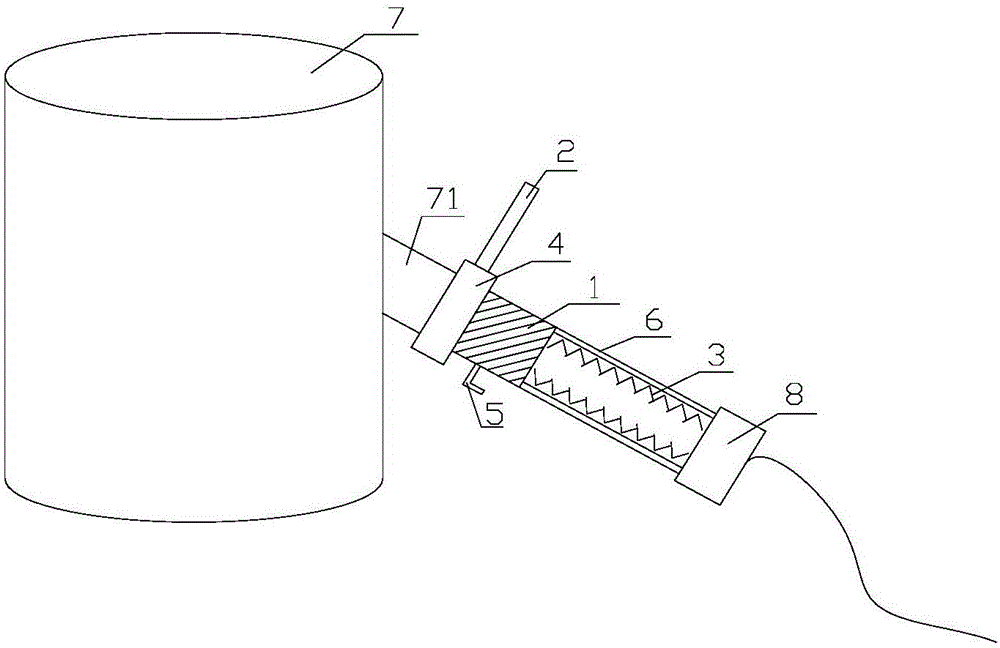

[0033] refer to figure 1 , the ion source maintenance device of the present invention is applied to the vacuum chamber 7 of the ion beam sputtering coating process, and an opening 71 is arranged on the vacuum chamber 7, and the ion source maintenance device of the present invention communicates with the vacuum chamber 7 through the opening 71 through connection.

[0034] Specifically, the ion source maintenance device of the present invention mainly includes: a seamless vacuum tube 1, one end of which is connected to the vacuum cavity 7 through a vacuum flange 4, the other end is connected to the vacuum bellows 3, and the other end of the vacuum bellows 3 is connected to There is an ion source end baffle 8, which acts as a seal. Additional devices such as cables are also connected to the other end of the ion source end baffle 8 . On the vacuum flange 4, a flapper valve 2 is provided, and the flapper valve 2 is opened, and the seamless vacuum tube 1 and the vacuum bellows 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com