Sliding guide drilling closed-loop control system and sliding guide drilling closed-loop control method

A closed-loop control and sliding-steering technology, which is applied in the automatic control system of drilling, directional drilling, drilling equipment, etc., can solve problems such as affecting drilling progress and increasing drilling cost, so as to improve wellbore quality, operation efficiency and control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

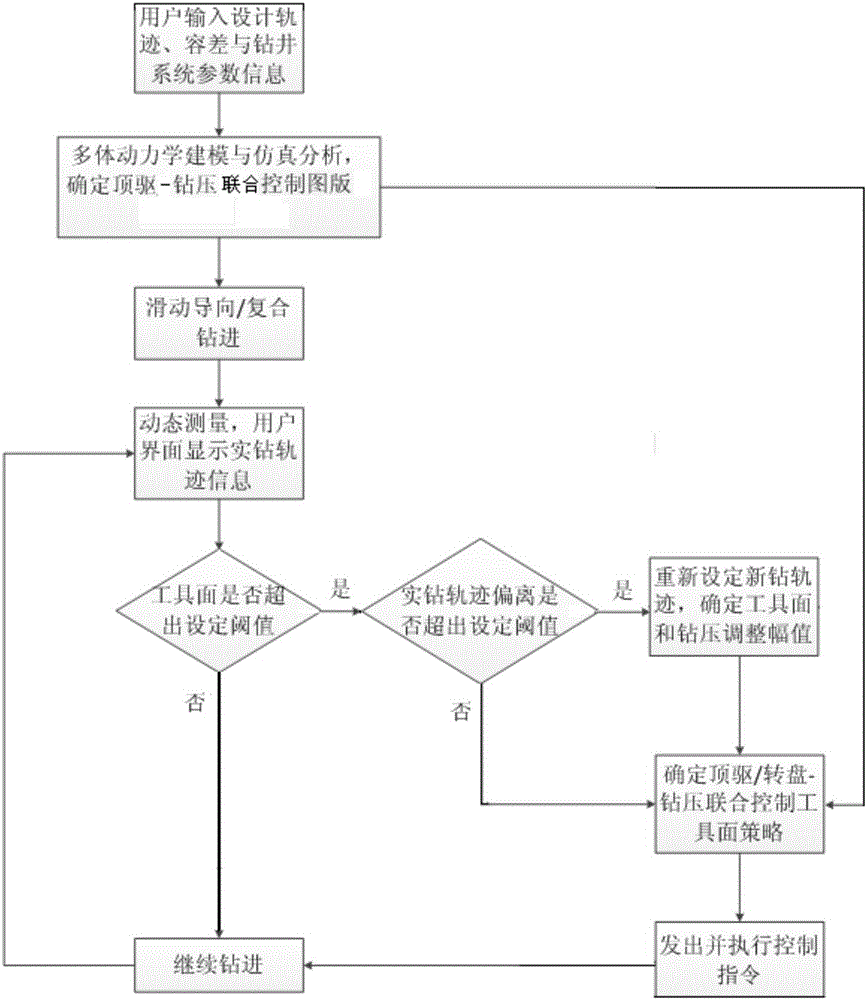

[0019] The present invention will be described in detail below with reference to the drawings and embodiments.

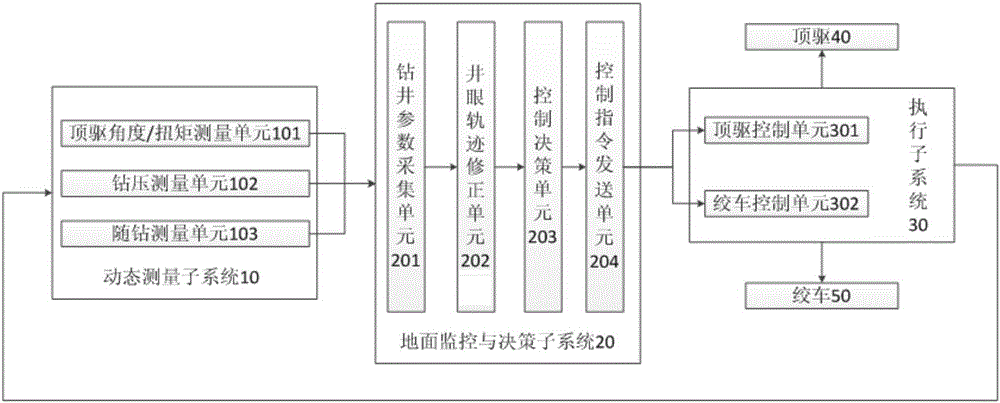

[0020] Such as figure 1 As shown, the closed-loop control system for sliding steering drilling of the present invention includes a dynamic measurement subsystem 10, a ground monitoring and decision-making subsystem 20, and an execution subsystem 30.

[0021] Among them, the dynamic measurement unit subsystem 10 includes a top drive angle / torque measurement unit 101 for measuring the top drive rotation angle or torque, a weight-on-bit measurement unit 102 for measuring the weight on bit / torque near the bit, and a The measurement-while-drilling unit 103 for measuring actual drilling hole trajectory parameters such as well deviation and azimuth and tool faces of downhole power drilling tools.

[0022] The ground monitoring and decision-making subsystem 20 includes a drilling parameter acquisition unit 201, a borehole trajectory correction unit 202, a control decision unit 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com