A kind of engine intermediate double helical gear transmission device

A transmission and helical gear technology, applied in transmission parts, machines/engines, transmission boxes, etc., can solve the problems of affecting the normal meshing of gears, large swing, etc., and achieve good reliability, reduced axial force, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

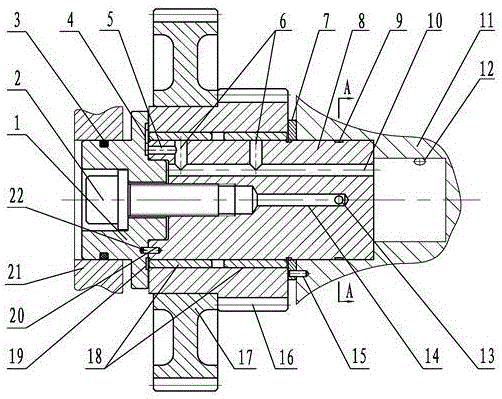

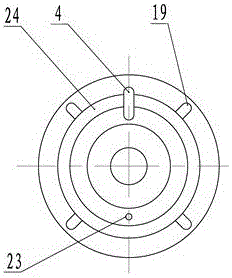

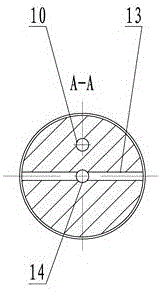

[0012] The present invention is described in conjunction with accompanying drawing and specific embodiment:

[0013] Such as figure 1 Shown, a kind of engine middle double helical gear transmission, described middle double helical gear transmission includes double helical gear and intermediate gear shaft 8; The right end of described intermediate gear shaft 8 is positioned at the body of engine and Interference fit with the body; the left end surface of the body 11 is provided with a thrust ring 7, the thrust ring 7 is in an annular structure, and the thrust ring 7 is sleeved on the intermediate gear on the shaft and in clearance fit with the intermediate gear shaft 8, the end face of one side of the thrust ring is closely attached to the end face of the body 11 through the positioning pin 15; the left end of the intermediate gear shaft 8 is provided with a support shaft 1; the left end face of the intermediate gear shaft 8 is The middle part has a groove for connecting with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com