Printing drying heat pump

A printing drying and heat pump technology, applied in printing, drying, dryer and other directions, can solve the problems of reducing the efficiency of air supply and heat recovery, reducing the effect of air supply and heat recovery, and complicated layout of air ducts, so as to improve the efficiency of air supply and heat recovery. The effect of air supply and heat recovery efficiency, reducing wind resistance energy consumption, and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. The schematic implementation and description of the present invention are used to explain the present invention, but are not intended to limit the present invention.

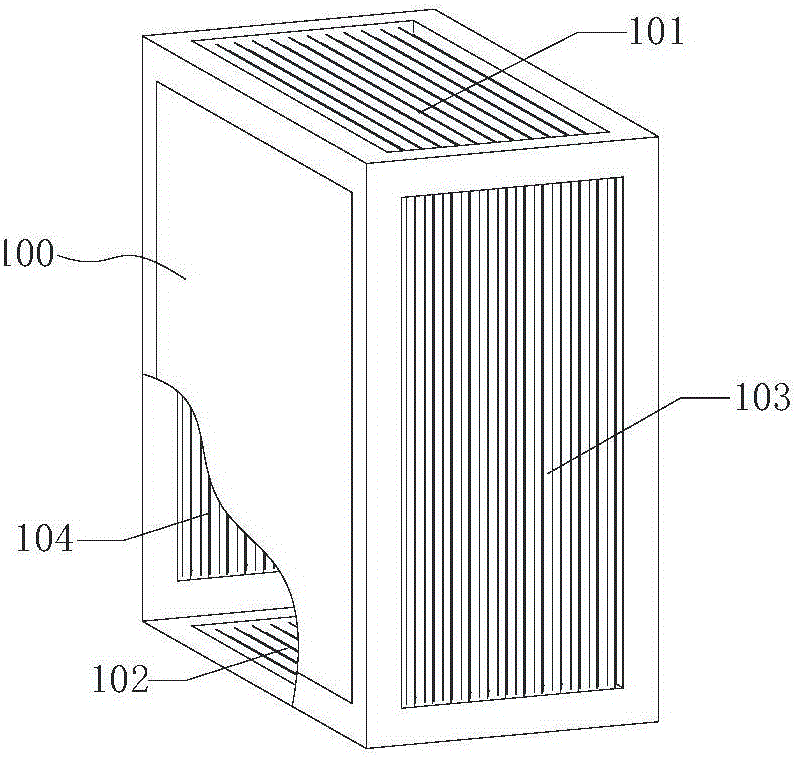

[0038] Such as image 3 As shown, it is a specific embodiment of the sensible heat exchanger 100 in the printing and drying heat pump of the present invention. The sensible heat exchanger 100 includes a fresh air inlet surface 101, and a The fresh air outlet surface 102 , the return air inlet surface 103 , and the return air outlet surface 104 facing the return air inlet surface 103 . in, image 3 In order to clearly show the fresh air outlet surface 102 and the return air outlet surface 104, it is pretended to be a partial section. In the figure, the sensible heat exchanger 100 is in the shape of a cuboid.

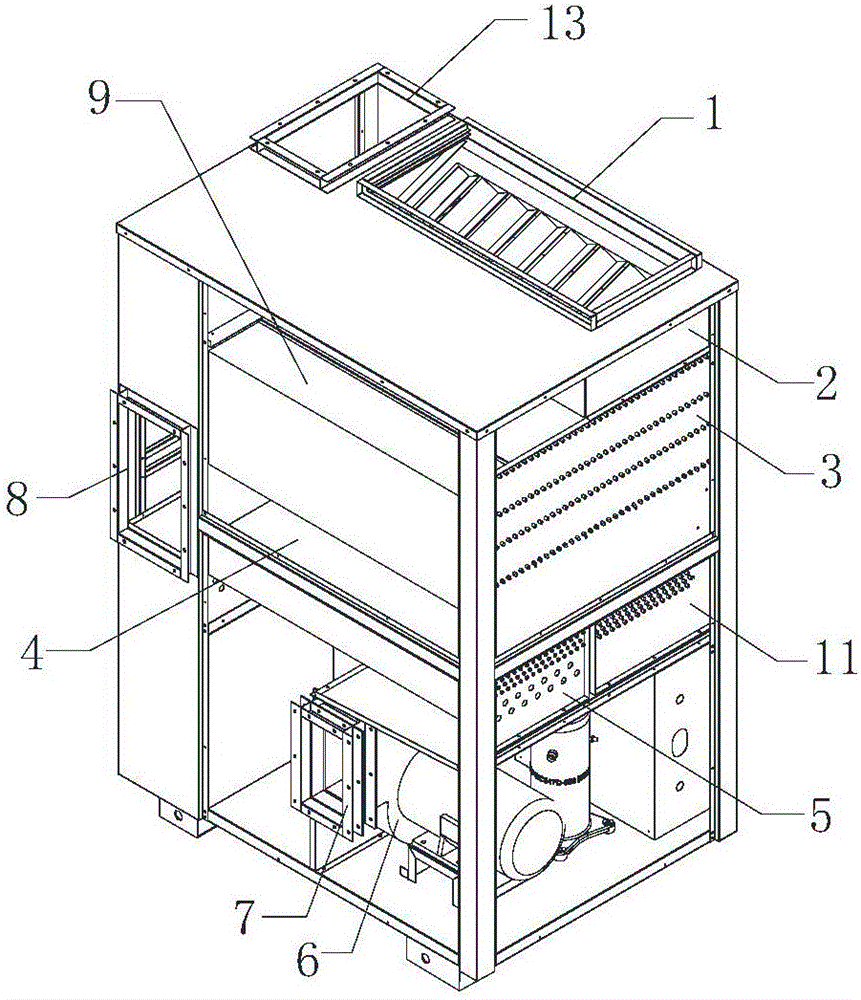

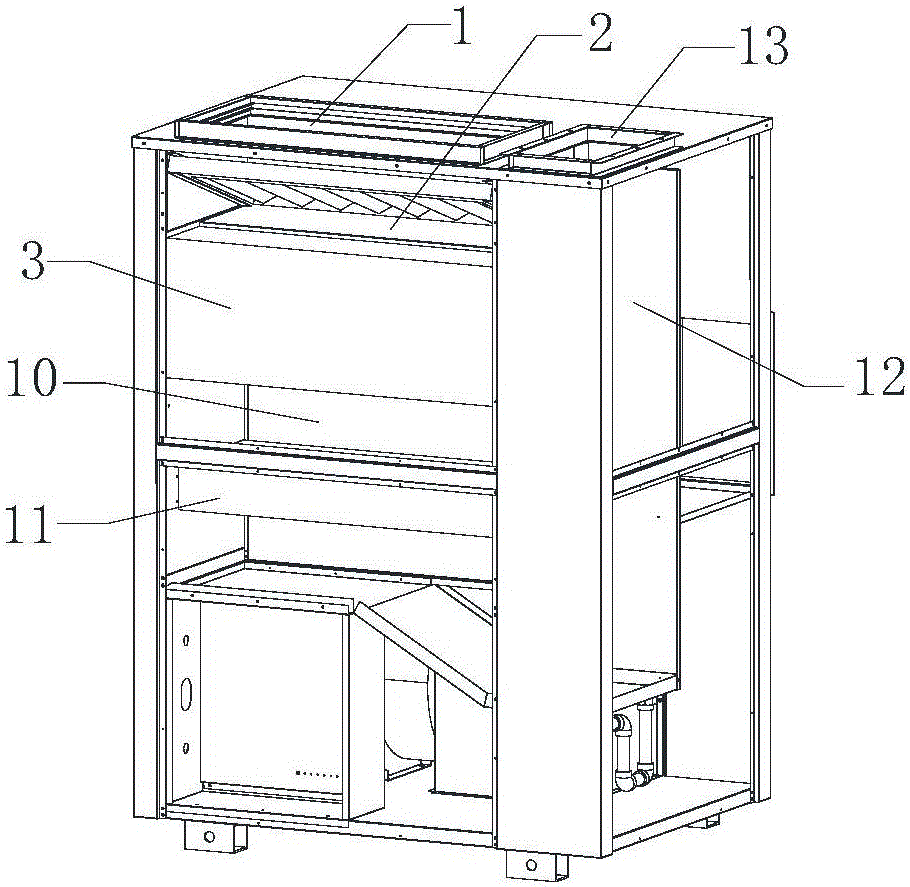

[0039] Such as Figure 4 Shown is a specific embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com