Grinding wheel external circle run-out detection method based on laser displacement sensor

A technology of laser displacement and detection method, which is applied in the field of mechanical precision machining, can solve the problems of multi-noise, unsuitable for frequency band filter processing, and cannot be used as a characterization parameter of the outer circle of the grinding wheel, so as to avoid human error, simple structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, but the following examples are only used to illustrate the present invention rather than limit the scope of the present invention.

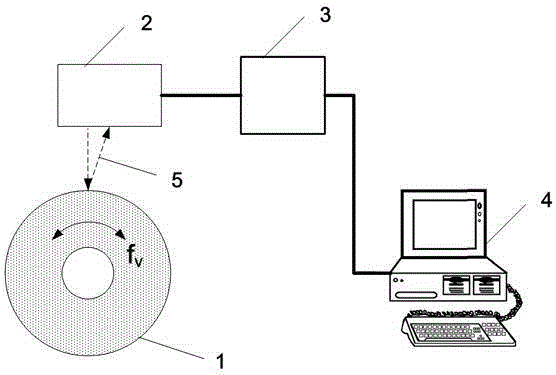

[0043] Such as figure 1 As shown, during the measurement, the tested grinding wheel 1 rotates at a certain safe speed; the laser displacement sensor 2 is installed directly in front of the outer surface of the tested grinding wheel 1, and the laser emission line 5 of the laser displacement sensor is perpendicular to the surface of the tested grinding wheel 1, The irradiation path of the laser spot passes through the center of the grinding wheel shaft; by connecting the data cable laser displacement sensor 2 to the controller 3, and the controller 3 to the computer 4, the data measured by the laser displacement sensor 2 can be transmitted to the computer 4; through software programming , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com