Large-torque steering engine servo system driven by brushless motor

A brushless motor and servo system technology, applied in the fields of angular displacement servo system, motor drive, mechanical design, and servo control, can solve the problems of structural strength and driving motor power limit, increasing the manufacturing cost of articulated robots, and high market prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following specific implementation methods will be described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

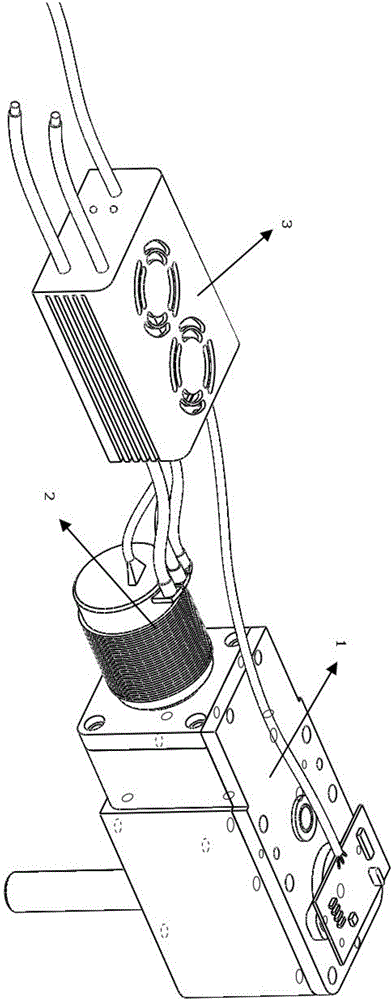

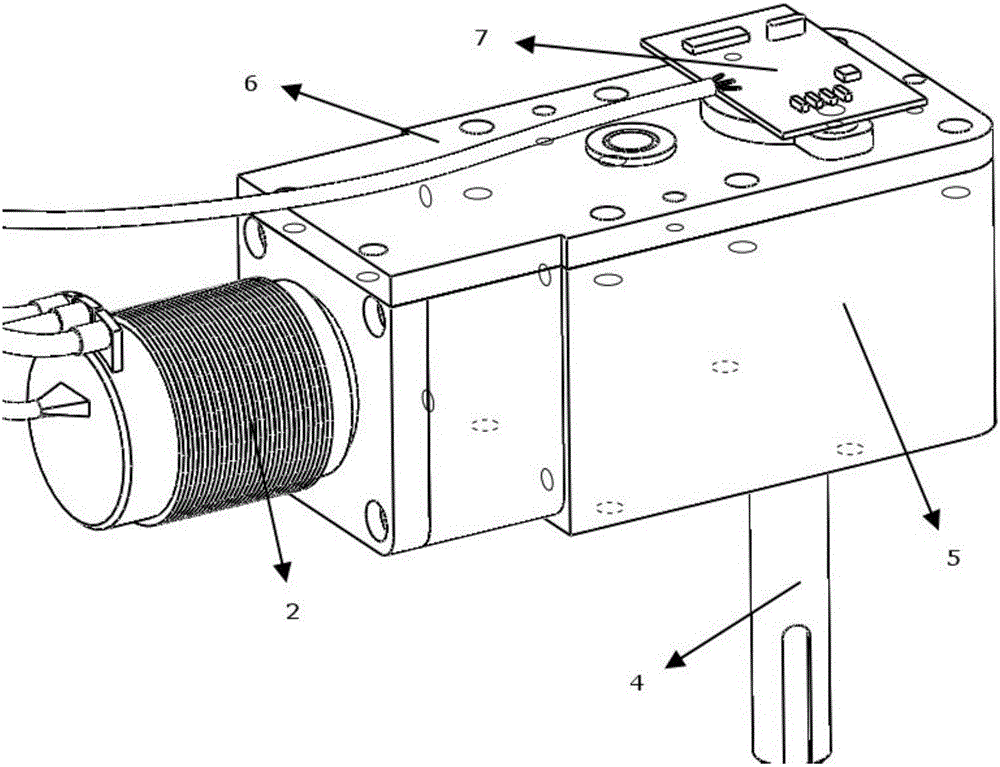

[0022] The overall device such as figure 1 , a high-torque steering gear servo system driven by a brushless motor, the system includes a steering gear reducer (1), a drive motor (2), a position detection and servo drive controller (3); a position detection and servo drive controller ( 3) The steering gear servo drive controller (27) controls the drive motor (2) to drive the output shaft (4) to rotate through the steering gear reducer (1).

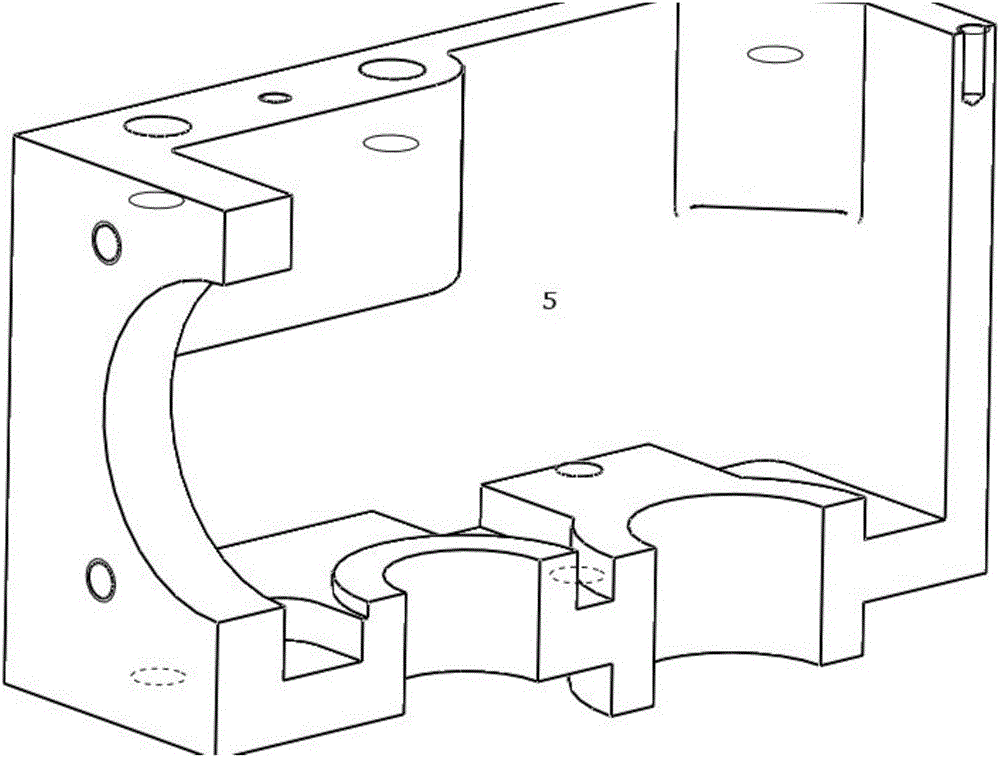

[0023] The main body of the steering gear is as figure 2 , the bevel gear reducer housing (5) and the steering gear reducer cover (6) are made of aluminum alloy casting, and its overall size is: 130×58×58mm; the bevel gear reducer housing (5) and the rudder The motor reducer cover (6) is connected by three ordinary hexagon socket screws and six hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com