Lithium-sulfur battery electrode and preparation method of lithium-sulfur battery containing the same

A lithium-sulfur battery and electrode technology, which is applied in the manufacture of battery electrodes, non-aqueous electrolyte battery electrodes, and electrolyte batteries, can solve the problems of lithium sulfide dissolution and diffusion, active material loss, and poor battery safety, and achieve industrialization in large quantities Production, blocking sulfide diffusion, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

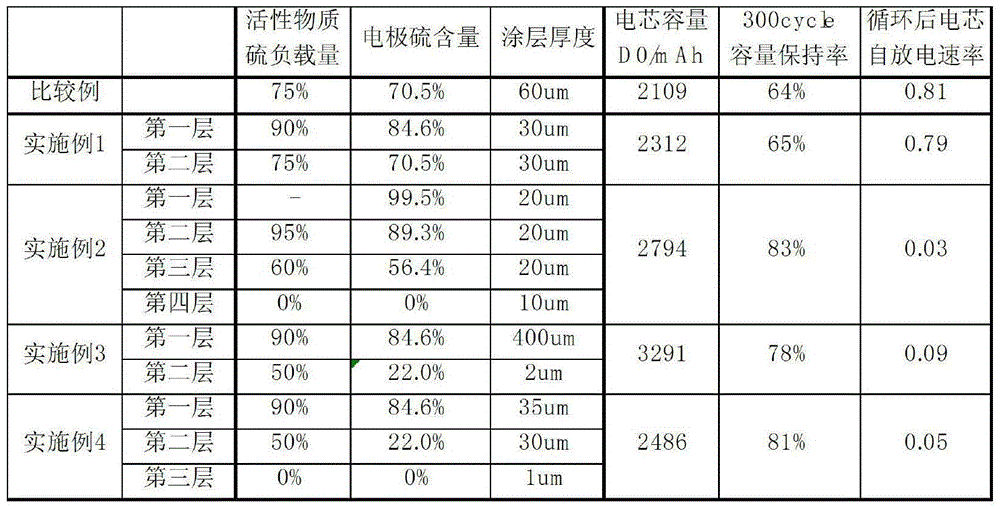

Embodiment 1

[0030] Preparation of the positive electrode sheet of the first coating layer: the sulfur-activated carbon composite (the loading capacity of sulfur is 90%), the binder, the conductive agent (the mass ratio of the above three substances is 94:3:3) and the solvent, The slurry 1 was obtained after thorough stirring, and then coated on an aluminum foil, and after cold pressing, a positive electrode sheet with a coating thickness of 30 μm on one side was obtained for use.

[0031] Preparation of the positive electrode sheet of the two-layer coating structure: the sulfur-activated carbon composite (the loading of sulfur is 75%), the binder, the conductive agent (the mass ratio of the above three substances is 94:3:3) and the solvent , after fully stirring, slurry 2 is obtained, and then coated on the surface of the above-mentioned first layer of coating layer, and after cold pressing, the second layer of coating layer thickness is obtained after cold pressing. - the particle size o...

Embodiment 2

[0034] Preparation of the positive electrode sheet of the first coating layer: fully stir the nano-sulfur particles, graphene, binder (99.5:0.3:0.2) and solvent to obtain a slurry, and then coat it on the aluminum foil, after cold pressing A positive electrode sheet with a coating thickness of 20 μm on one side was obtained for use.

[0035] Preparation of the positive electrode sheet of the two-layer coating structure: the sulfur-graphene composite (the loading of sulfur is 95%) and the binder, the conductive agent (the mass ratio of the above three substances is 94:3:3) and the solvent , after fully stirring to obtain slurry 2, and then coating on the surface of the first coating layer, and cold pressing to obtain a two-layer positive electrode sheet with a thickness of the second coating layer of 20 μm for use.

[0036]The preparation of the positive plate of the three-layer coating structure: the sulfur-graphene composite (the loading capacity of sulfur is 60%) and the bin...

Embodiment 3

[0040] Preparation of the positive electrode sheet of the first coating layer: the sulfur-ketjen black compound (the loading capacity of sulfur is 90%), the adhesive, the conductive agent (the mass ratio of the above three substances is 94:3:3) and the solvent , the slurry 1 was obtained after fully stirring, and then coated on an aluminum foil, and after cold pressing, a positive electrode sheet with a single-side coating thickness of 400 μm was obtained for use;

[0041] Preparation of positive electrode sheet with two-layer coating structure: Nano-lithium iron phosphate, sulfur-conductive carbon composite (the loading of sulfur is 50%), binder, conductive agent (the mass ratio of the above four substances is 50:44 :2:4) and solvent, fully stirred to obtain slurry 2, then coated on the surface of the first layer of coating layer, after cold pressing to obtain a second layer of coating layer thickness of 2 μm of the two-layer positive electrode sheet for use .

[0042] Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com