Pot seedling transplanter full-automatic seedling supply apparatus

A transplanting machine, fully automatic technology, applied in the field of agricultural machinery, can solve the problem that the efficiency of transplanting operation cannot meet the requirements of large-area transplanting operations, there is no machine tool that can meet the requirements of seedling tray transplanting operations, and cannot meet the requirements of large-area transplanting problems such as homework, to achieve the effect of increasing the yield per unit area of crops, novel structure, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

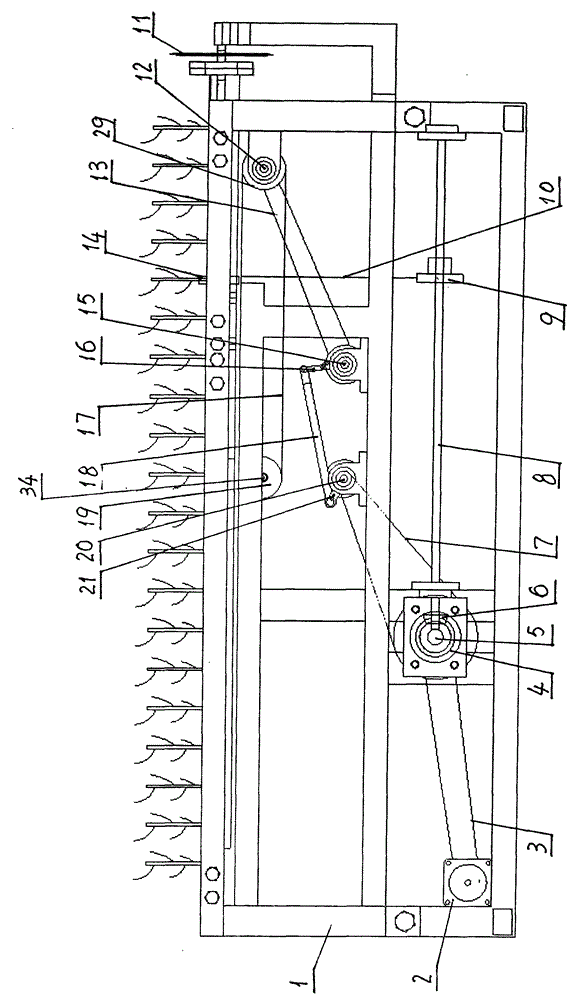

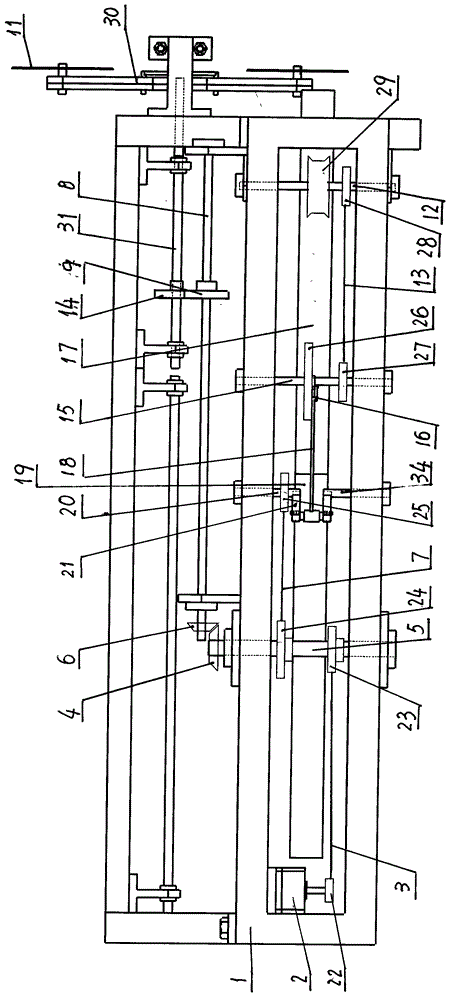

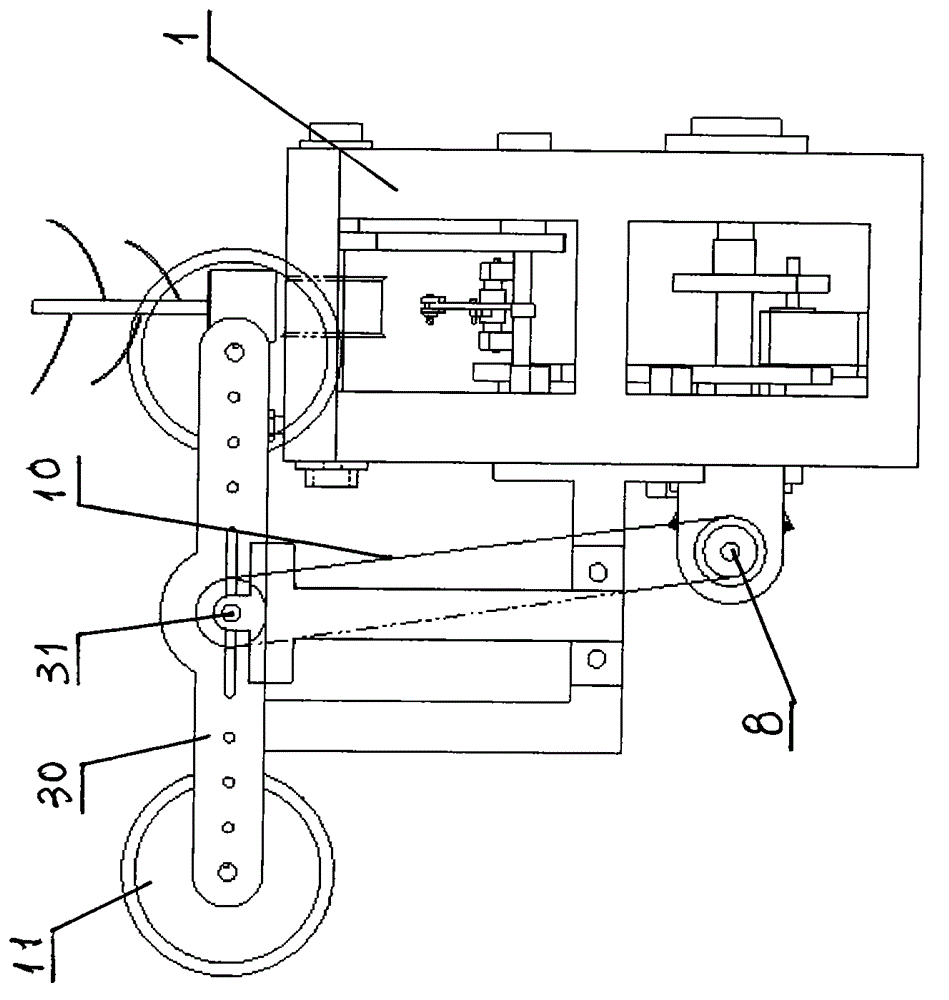

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A fully automatic seedling supply device for pot seedling transplanting machines, the motor 2 with the first sprocket 22 is fixed on the frame assembly 1, and the motors 2 are mounted on the frame assembly 1 parallel to each other and rotatable in turn. I shaft 5, III shaft 20, VII shaft 34, IV shaft 15 and V shaft 12, on the I shaft 5, the second sprocket 23, the fifth sprocket 24 and the driving bevel gear 4 are fixed, and the crank 21 is fixed The sixth sprocket 25 is fixed on the III shaft 20, the driven synchronous pulley 19 is fixed on the VII shaft 34, the ratchet 26 and the seventh sprocket 27 are fixed on the IV shaft 15, and on the ratchet 26 The swing rod 16 is installed, the two ends of the connecting rod 18 are hingedly connected with the crank 21 and the swing rod 16 respectively, the eighth sprocket 28 and the active synchronous pulley 29 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com