High-density oyster breeding equipment

A high-density, nursery equipment technology, applied in fish farming, application, climate change adaptation, etc., to achieve the effect of increased utilization, reduced labor intensity, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] High-density oyster cultivation equipment in outdoor nursery ponds is used for single oyster cultivation.

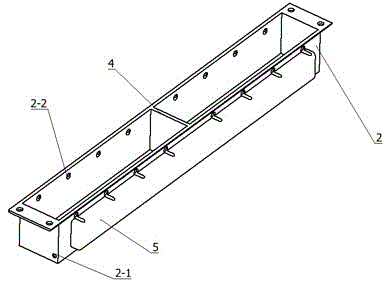

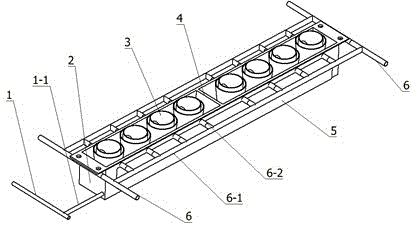

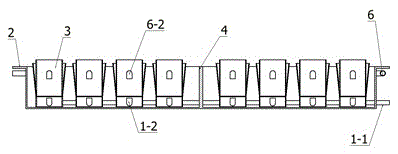

[0036] Outdoor 10 mu of seedling ponds apply the high-density oyster cultivation equipment of the present invention to carry out single oyster cultivation, take the sump as the seedling unit, and design the sump according to the actual size of the seedling pond, such as figure 1 As shown, the length*width*height of the water collection tank is 4m*0.5m*0.6m. A balance vacuum bag is arranged longitudinally on the outer wall, such as figure 2 with image 3 As shown, 8 seedling buckets can be placed in each sump, and 4 seedling buckets can be placed on each side of the horizontal balance partition to form a seedling unit; Figure 4 As shown, 4 water collection tanks form a group, and 8 groups are placed in the nursery pond.

[0037] Such as Figure 5 As shown, the seedling raising barrel includes an inner barrel and an outer barrel, and an open plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com