Method for preparing hydrothermal biomass charcoal from pecan shells

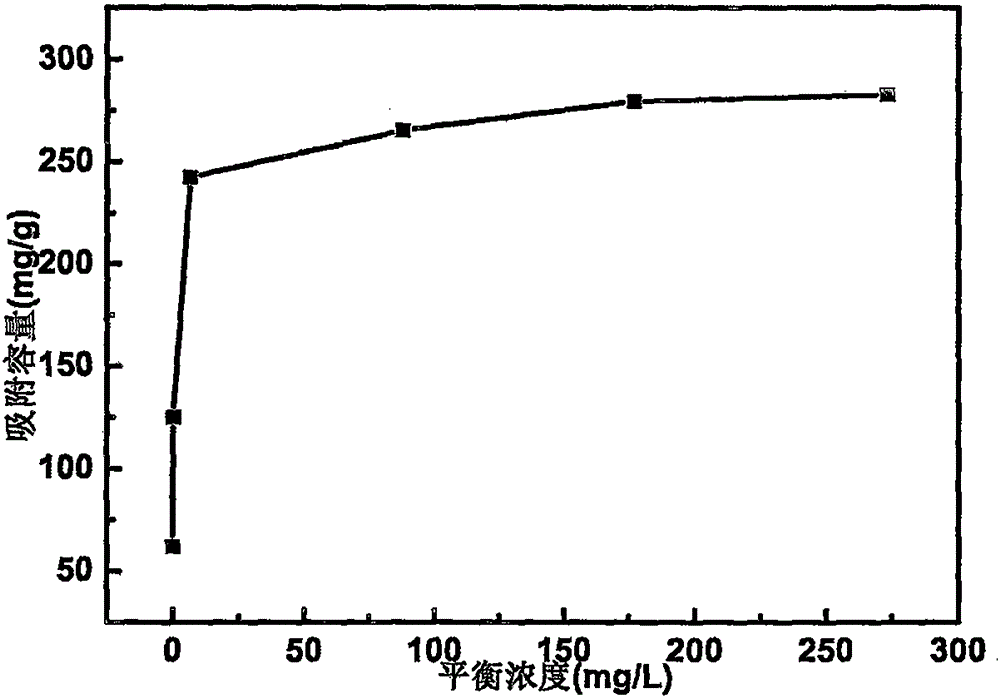

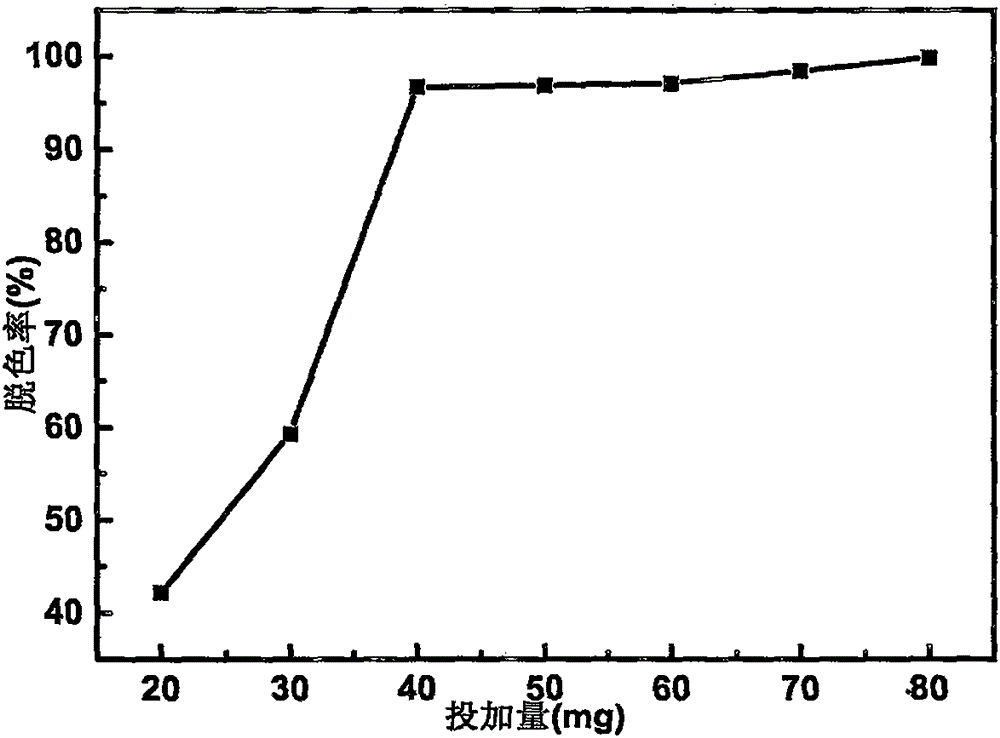

A technology of biomass charcoal and hickory shell, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effect of increasing added value and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

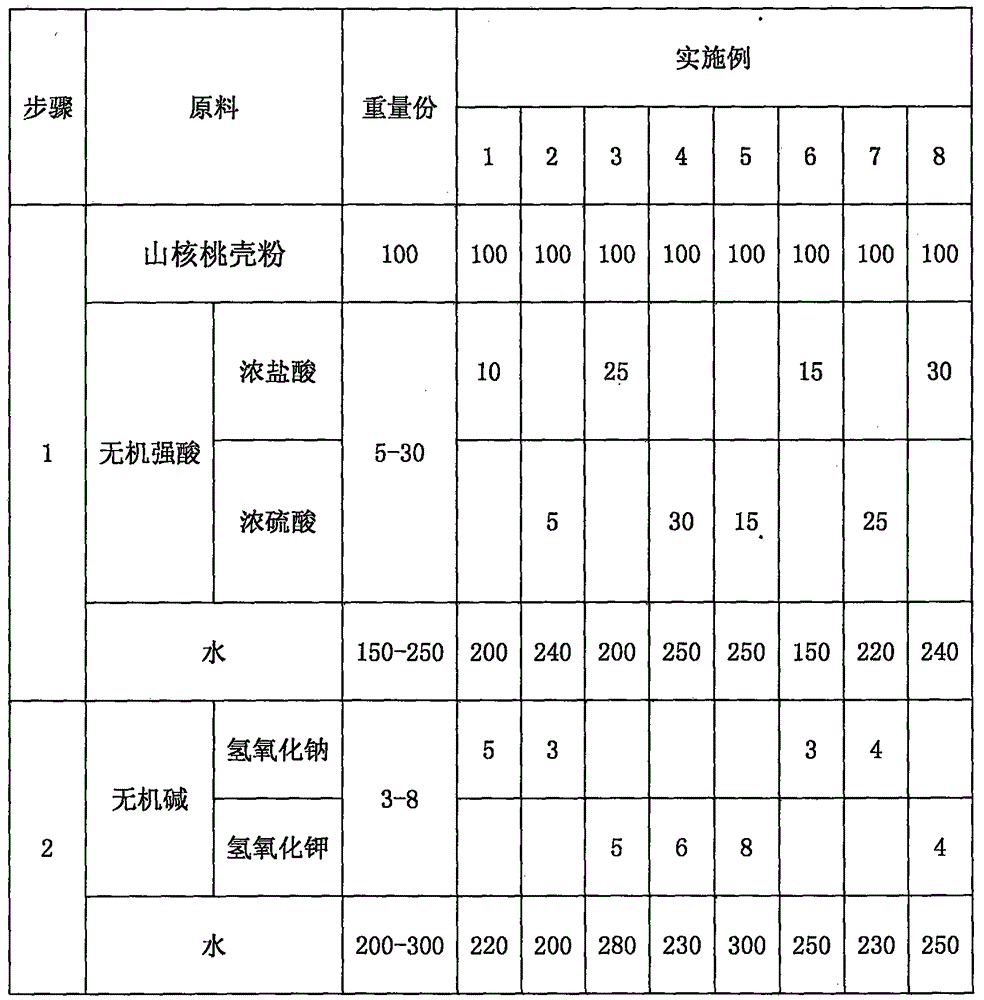

[0018] Embodiment 1 (corresponding embodiment 1 and the proportioning value by weight in contrasting table above), prepare as follows according to the following steps:

[0019] (1) Pecan shells are pulverized into 60-80 order pecan shell powder;

[0020] (2) Preparation of hydrothermal biochar: 100 parts by weight of 60-80 mesh hickory nut shell powder and 10 parts by weight of concentrated hydrochloric acid with a concentration of 37% are placed in 200 parts by weight of water, stirred and mixed evenly at room temperature and placed in In a stainless steel reaction kettle lined with polytetrafluoroethylene, react at 220°C for 8 hours, cool naturally, filter with suction, and wash until neutral to obtain hydrothermal biochar;

[0021] (3) Preparation of activated hydrothermal biochar: mix the hydrothermal biochar obtained in step (2) with 5 parts by weight of inorganic alkali and 220 parts by weight of water, stir at room temperature for 2 hours, suction filter, wash to neutra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com