Fixed seam expanding device and welding equipment for thin-walled plate cylinder

A technology of expansion device and welding equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inability to locate the position of the seam, and achieve good welding seam forming quality, high welding efficiency, Fast centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

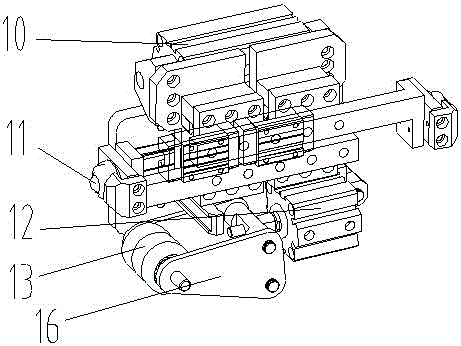

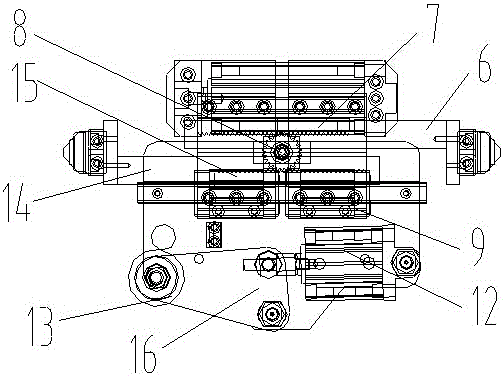

[0035]A thin-walled plate cylinder fixed seam expansion device, the fixed seam expansion device mainly acts on the thin-walled and unclosed cylinder 4 (that is, the cylinder 4 with joints), and is used to expand the gap size of the welded joint , so as to accurately locate the position of the seam.

[0036] The thin-walled plate cylinder fixed seam expansion device includes a base body on which a telescopic synchronous gear 8, an upper expansion telescopic rod 6 and a lower expansion telescopic rod 14 are arranged, wherein the telescopic synchronous gear 8 can be wound around the base body. When the axis rotates, the upper expansion telescopic rod 6 and the lower expansion telescopic rod 14 can move back and forth along their respective length directions on the base body. The upper expansion telescopic rod 6 is connected with an upper telescopic synchronous rack 7, and the upper expansion telescopic rod 6 and the upper telescopic synchronous rack 7 move synchronously together;...

Embodiment 2

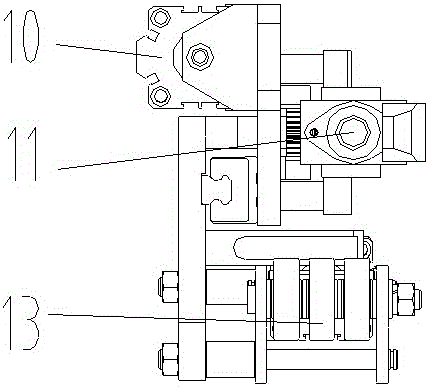

[0042] On the basis of the first embodiment, a universal ball 11 is provided on the outer end surface of the upper expansion telescopic rod 6 , and a universal ball 11 is provided on the outer end surface of the lower expansion telescopic rod 14 . When expanding the cylinder 4, the universal ball 11 on the upper expansion telescopic rod 6 and the universal ball 11 on the lower expansion telescopic rod 14 are all in contact with the inner wall of the cylinder 4, so that the thin-walled cylinder 4 does not need to be rotated when the cylinder 4 is rotated. Plate cylinder fixed seam expansion device.

[0043] Universal balls 11 are all arranged on the outer end faces of the upper expansion telescopic rod 6 and the outer end faces of the lower expansion telescopic rods 14. When expanding the joints of the cylinder body 4, the universal balls 11 directly contact the inner wall of the cylinder body 4; A universal ball 11 is arranged between the telescopic rod and the cylinder 4, so ...

Embodiment 3

[0045] On the basis of Embodiment 1 or Embodiment 2, one side of the base body is also connected with an installation seat 1 for installing the counter knife 3 , wherein the installation seat 1 is arranged on the side of the base body away from the cylinder body 4 to be processed. The mounting base 1 is connected with a seam knife 3, and the side of the seam knife 3 close to the cylinder body 4 to be processed is provided with an introduction seam knife 2, which is used for introducing the seam of the cylinder body 4 middle. Both the seam knife 3 and the imported seam knife 2 are made of high-hardness materials.

[0046] Preferably, the caulking knife 3 is arranged as a sandwich structure, and the trachea and cables of the expansion device are located in the interlayer of the caulking knife 3 .

[0047] One side of the base body is connected with a mounting base 1 for installing the seam knife 3, and the seam knife 3 is connected to the installation, and the seam knife 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com