High temperature resistant overall hydrophobic insulation material and preparation method thereof

A hydrophobic thermal insulation material and high temperature resistant technology, applied in the field of thermal insulation materials, can solve the problems of low mechanical strength, unsatisfactory hydrophobic effect, and failure of hydrophobic effect of calcium silicate thermal insulation materials, achieve excellent product competitiveness, overcome hydrophobicity and other problems. The effect of poor water performance and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

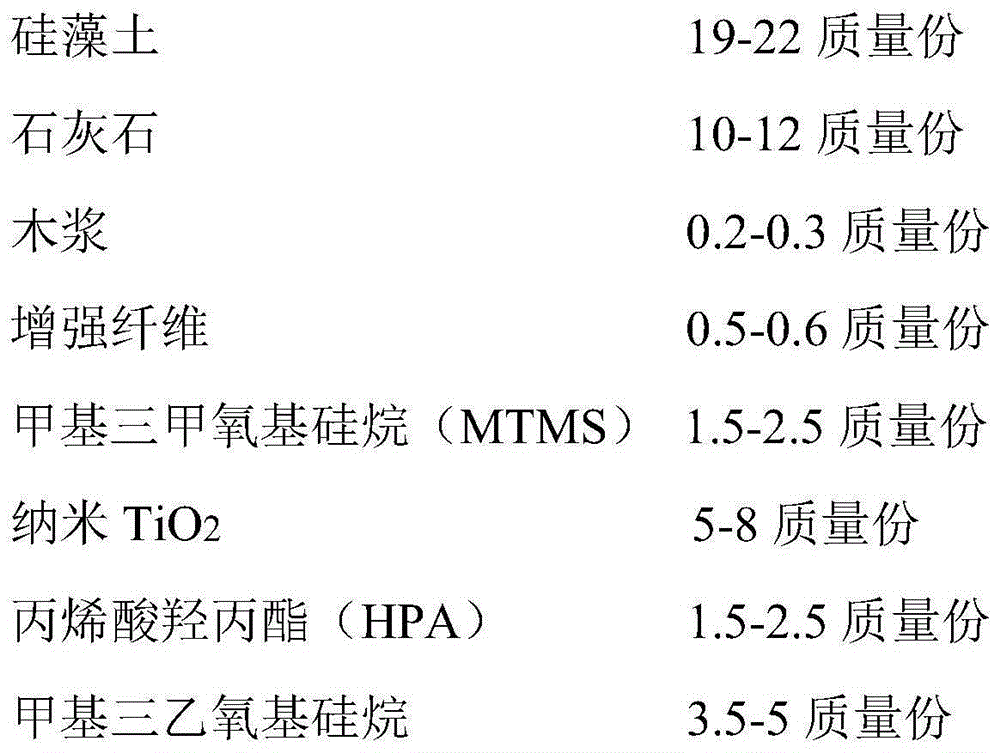

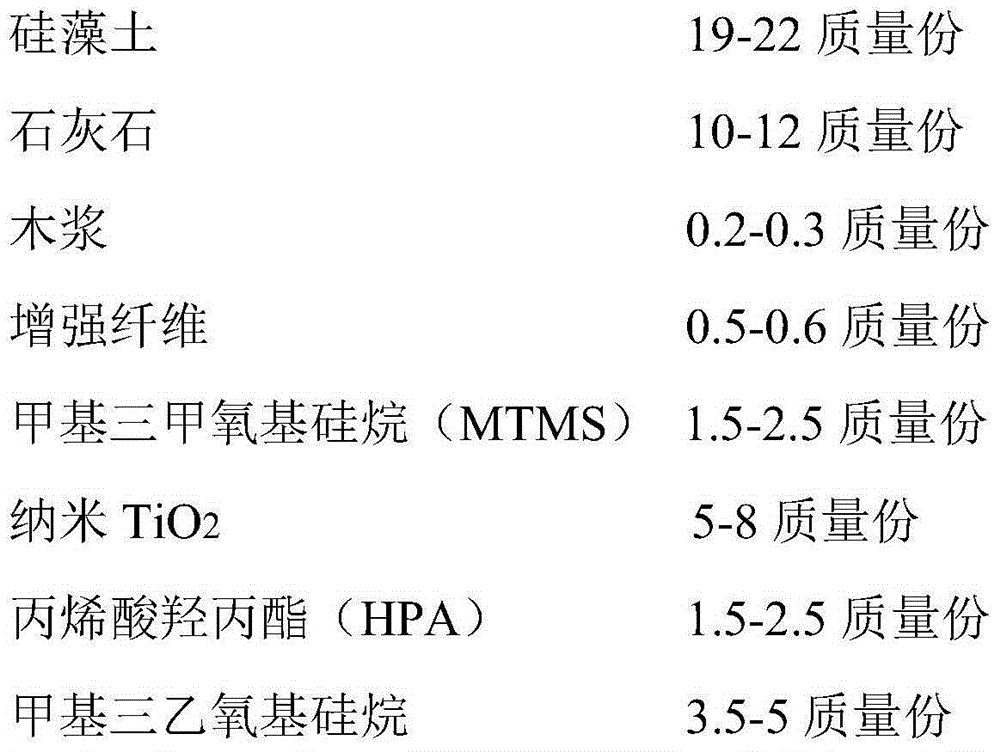

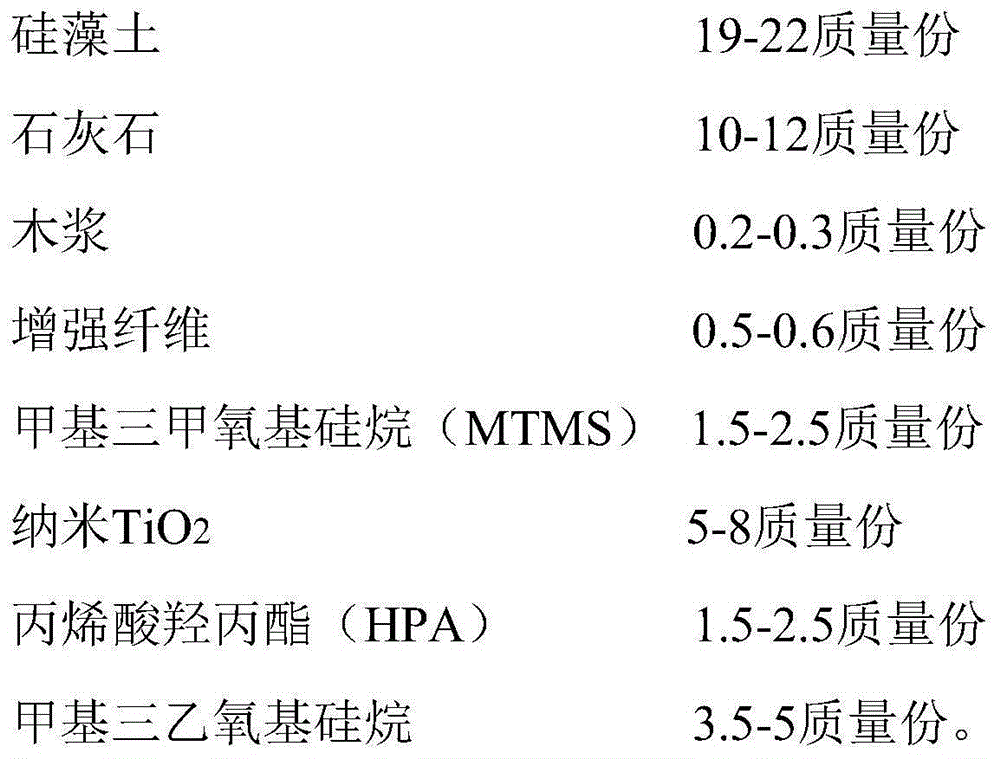

Method used

Image

Examples

Embodiment 1

[0064] Take 15 parts by mass of diatomite, 10 parts by mass of limestone emulsion, 48 parts by mass of water, 0.6 parts by mass of reinforcing fiber and 0.3 parts by mass of wood pulp and mix to obtain the first mixed solution; the temperature of the first mixed solution is at 97°C , steam heating under the pressure of 1.0MPa, gel reaction for 6h, and obtain a gel product after discharging; take 5 parts by mass of diatomaceous earth and 4 parts by mass of methyltriethoxysilane, stir and mix in a mixer for 2h, After stirring and mixing, a uniform second mixed liquid is obtained; the second mixed liquid and the gel product are stirred and mixed for 1 hour, and after stirring and mixed, a uniform third mixed liquid is obtained. Then the third mixed hydraulic pressure was made into a green body, which was autoclaved in an autoclave at 150° C. and 0.5 MPa for 8 hours. After the autoclaving was completed, the green body was dried and a sample was prepared to obtain a product.

[006...

Embodiment 2

[0071] Take 16 parts by mass of diatomite, 12 parts by mass of limestone emulsion, 45 parts by mass of water, 0.5 parts by mass of reinforcing fiber and 0.2 parts by mass of wood pulp and mix to obtain the first mixed solution; the temperature of the first mixed solution is at 95°C , steam heating under the pressure of 0.7MPa, gel reaction for 6h, and obtain a gel product after discharging; take 4 mass parts of diatomaceous earth and 4 mass parts of methyltriethoxysilane, stir and mix in a mixer for 2h, After stirring and mixing, a uniform second mixed liquid is obtained; the second mixed liquid and the gel product are stirred and mixed for 1 hour, and after stirring and mixed, a uniform third mixed liquid is obtained. Then the third mixed hydraulic pressure was made into a green body, which was autoclaved in an autoclave at 150° C. and 0.5 MPa for 8 hours. After the autoclaving was completed, the green body was dried and a sample was prepared to obtain a product.

[0072] Get...

Embodiment 3

[0078]Take 17 parts by mass of diatomite, 11 parts by mass of limestone emulsion, 46 parts by mass of water, 0.56 parts by mass of reinforcing fiber and 0.25 parts by mass of wood pulp to obtain the first mixed solution; the temperature of the first mixed solution is at 96°C , steam heating under the pressure of 0.8MPa, gel reaction for 6h, and obtain a gel product after discharging; take 4 mass parts of diatomaceous earth and 4 mass parts of methyltriethoxysilane, stir and mix in a mixer for 2h, After stirring and mixing, a uniform second mixed liquid is obtained; the second mixed liquid and the gel product are stirred and mixed for 1 hour, and after stirring and mixed, a uniform third mixed liquid is obtained. Then the third mixed hydraulic pressure was made into a green body, which was autoclaved in an autoclave at 150° C. and 0.5 MPa for 8 hours. After the autoclaving was completed, the green body was dried and a sample was prepared to obtain a product.

[0079] Get 8 mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com