Rail vehicle large wire manufacturing system design and production method

A rail vehicle and system design technology, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of not accepting R&D and customized equipment, high equipment operation efficiency, low system efficiency, etc., and achieve system efficiency Improve, improve production efficiency, reduce the effect of staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

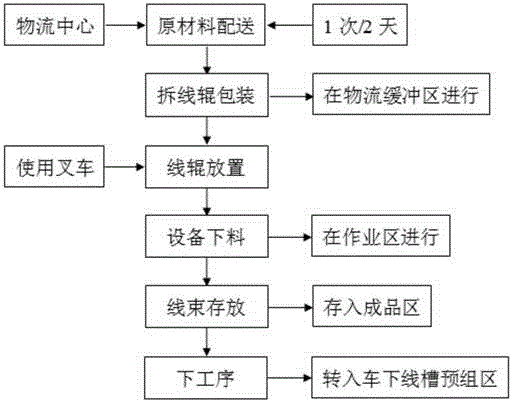

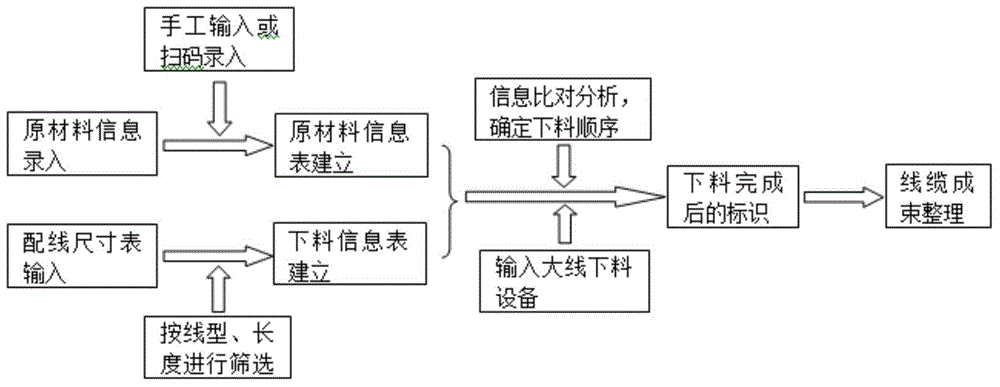

[0043] Through the research and analysis of the same industry and the cable harness manufacturing industry at home and abroad, the equipment for quickly and efficiently cutting cables is widely used, but it lacks the optimization of the bottleneck problem of low system efficiency caused by the replacement of multiple varieties and specifications of cables.

[0044] The main purpose of the present invention is to solve the problems existing in the design and manufacturing method of the electrical wire harness of the existing rail transit vehicles, and to provide a cable that can fully combine the characteristics of multiple wire types, thick wire diameters, and variable lengths of the rail vehicle cable operation, while taking into account production. Influenced by production factors such as demand and material matching, optimize the selection and configuration to form the optimal design and production method of the large-line automatic unloading system.

[0045] A method for de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com