Transformer iron core and manufacture method thereof

A manufacturing method and transformer technology, applied in the field of transformers, can solve the problems of limited improvement, reduced winding inductance, large magnetic leakage, etc., and achieve the effect of preventing magnetic leakage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

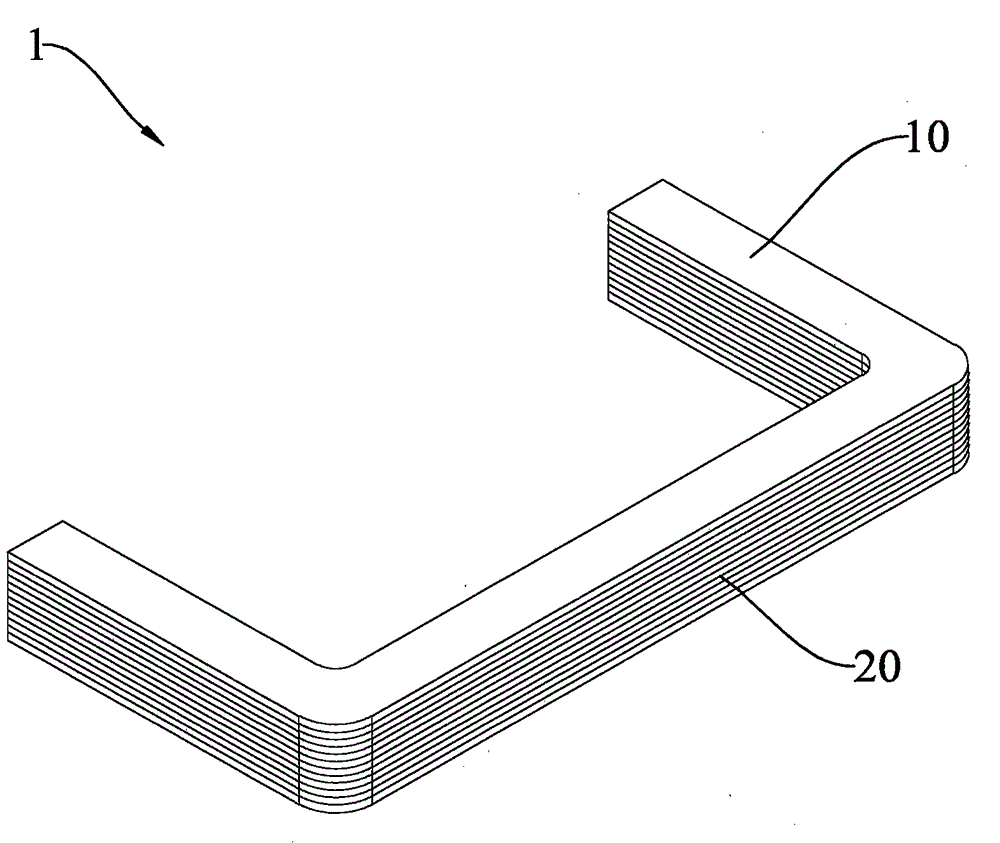

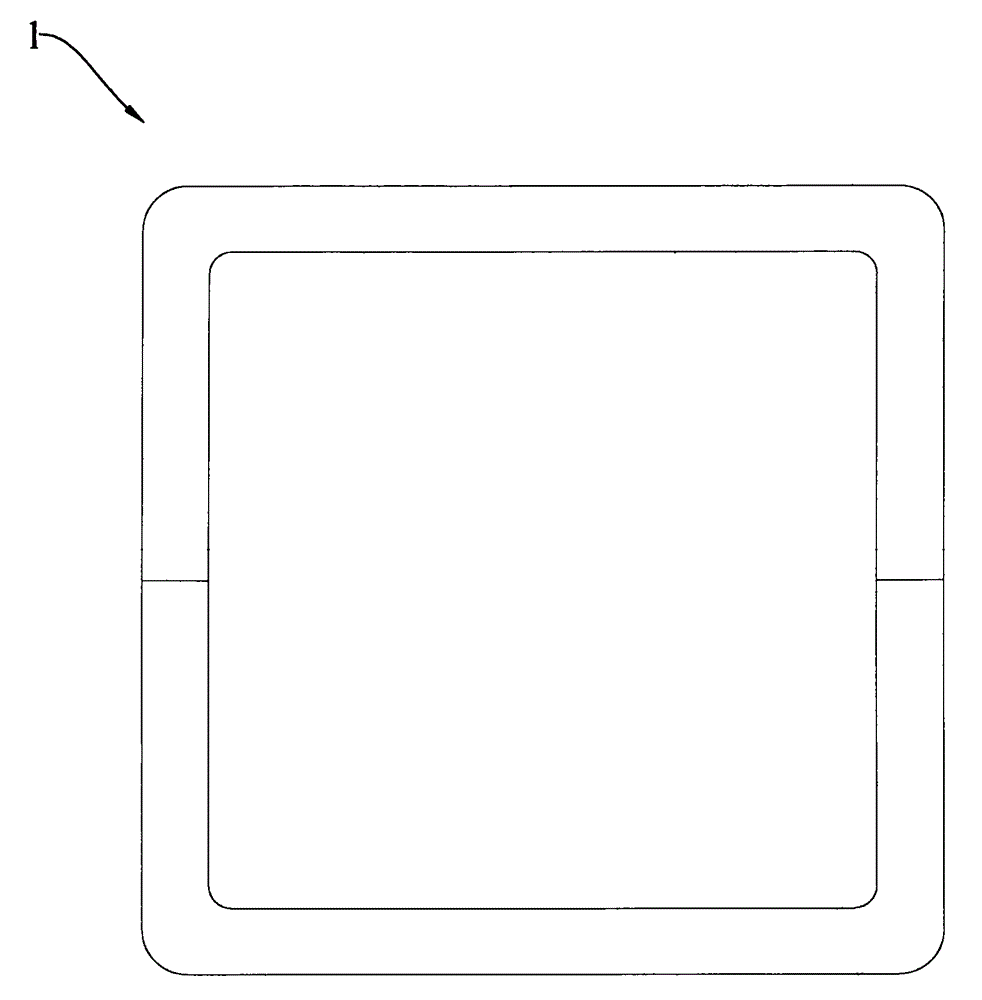

[0069] A method for manufacturing a transformer core 1, comprising the steps of:

[0070] Provide multiple sets of core laminations, each set of core laminations includes a pair of top and bottom outer core laminations 10, and a plurality of inner core laminations 20 to be processed;

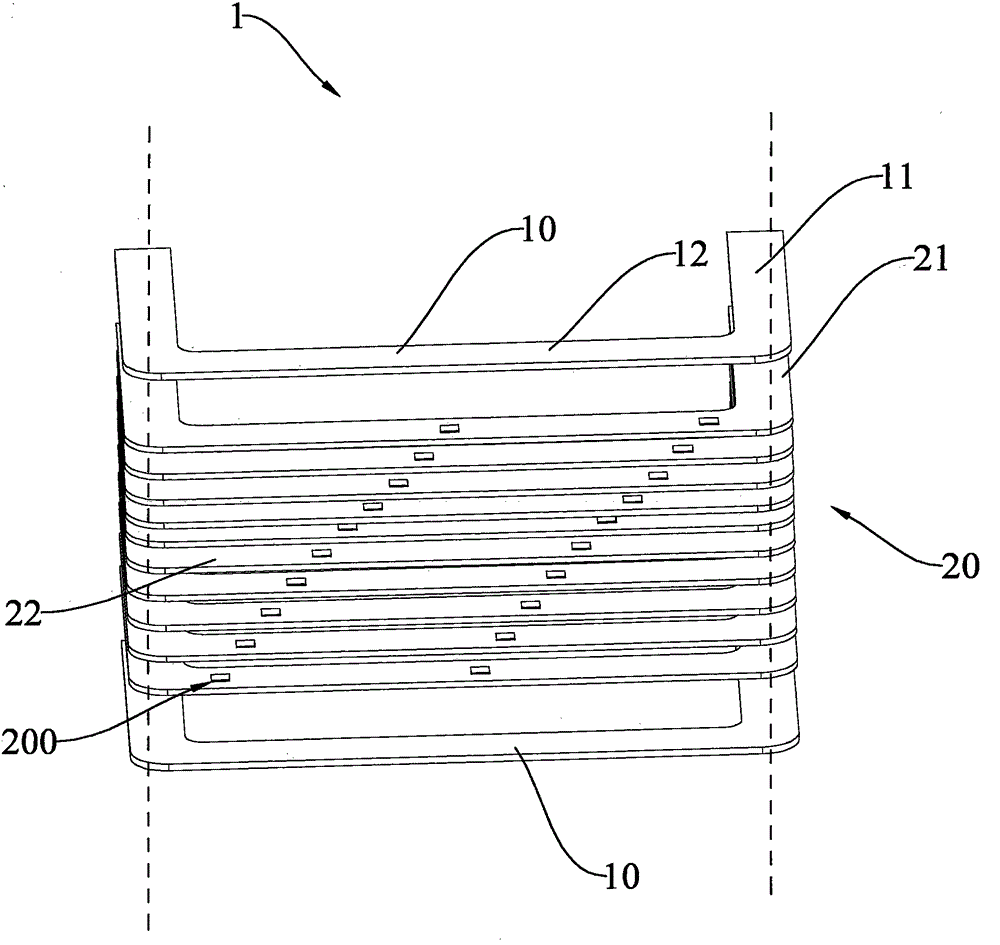

[0071] grouping the inner core sheets 20, and grouping the core sheets at the same processing position into one group;

[0072] Determining the slotting preset positions of the inner core pieces 20 in each group can determine the preset positions through the punch bottom die, so as to avoid that the core slots 200 of the adjacent inner core pieces 20 are on the same longitudinal section during the slotting process Appear;

[0073] Superimpose and fix the inner iron core sheets 20 of the same group, slot the inner iron core sheets 20 of the same group by a punching machine, and form iron core slots 200 on each of the inner iron core sheets 20, if there are too many inner iron core sheets 20 in t...

Embodiment 2

[0079] providing a set of core laminations, said core laminations comprising a pair of top and bottom outer core laminations 10, and a plurality of inner core laminations 20 to be processed;

[0080] At the same time, the slotting preset position of the inner core sheet 20 is determined, and the inner core sheet 20 is punched and molded once by means of a multi-punching upper die and a multi-positioning lower die, wherein the inner core sheets 20 are placed in sequence , determine the slotting preset position of each inner core sheet 20, punch a plurality of core slots 200 in the inner core sheet 20 at one time, and obtain one silicon steel sheet with different positions of the iron core slots 200;

[0081] According to the positions of the core slots 200 of each of the inner core sheets 20, sequentially bonding and stacking each of the inner core sheets 20 to complete the lamination of the inner core sheets 20; and

[0082] The outer core sheet 10 is respectively bonded to th...

Embodiment 3

[0085]Provide multiple sets of core laminations, each set of core laminations includes a pair of top and bottom outer core laminations 10, and a plurality of inner core laminations 20 to be processed;

[0086] grouping the inner core sheets 20, and grouping the core sheets at the same processing position into one group;

[0087] Determine the slotting preset position of the iron core sheet 20 in each group, and drill a round hole at the slotting center position of each group by a drilling machine;

[0088] Cutting the inner core sheet 20 through the circular hole line for slotting of the inner core sheet 20, so that each inner core sheet 20 is provided with at least one core slot 200;

[0089] Arranging the inner core pieces 20 with the core slots 200 in partitions, placing the inner core pieces 20 at the same slotting position in the same area, and placing the inner core pieces 20 in sequence according to the slotting positions ;

[0090] Taking out a piece of inner core sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com