Space solar cell composite interconnection material and preparation method thereof

A technology for interconnecting materials and solar cells, applied in the field of composite interconnecting materials for space solar cells and their preparation, can solve the problems of cracking of coatings and silver foils, corrosion and exhaustion of silver foils, and difficulty in completely blocking atomic oxygen corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0057] Preparation and characterization of molybdenum-silver alloy thin films.

[0058] Co-deposition of Mo by sputtering on N-type single-sided polished Si substrate x Ag y Alloy, substrate cleaning and thin film sputtering processes are as follows:

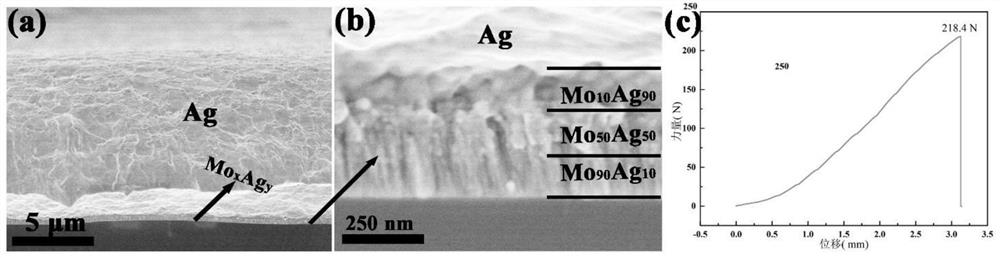

[0059] Firstly, the single-sided polished Si wafer with a size of 10 mm×10 mm was soaked in acetone and alcohol solutions for 20 minutes, then ultrasonically cleaned for 20 min, dried in a blast drying oven, and installed on a magnetron sputtering (MIS800) workstation. ,Such as figure 1 As shown in (a), the sample is located on a concentric circle with a distance of 20 mm from the center of the sample stage;

[0060] Then, the rotating speed of the sample stage is adjusted to be 5rpm, the vertical target spacing is 55cm, the inclination angle of the silver target and the molybdenum target is adjusted to be 30°, and the two target center extension lines intersect at the center of the sample stage (such as figure 1 (a) sputter...

Embodiment 1

[0065] The Mo that embodiment 1 obtains x Ag y The distribution of elements in the alloy film is as follows: figure 1 As shown in (c), the results show that when the sample rotation speed is 5r / min, the Mo and Ag elements in the film are evenly distributed. The high-resolution image shows that there are amorphous regions in the sample, and more crystalline regions. Electron diffraction (inset) revealed a polycrystalline structure of the film. The crystal structure of the above sample was analyzed, and its X-ray diffraction pattern was as follows: figure 1 As shown in (d), the results show that Mo x Ag y The alloy film is mainly composed of Mo(Ag) solid solution, pure Ag phase and amorphous phase.

Embodiment 3

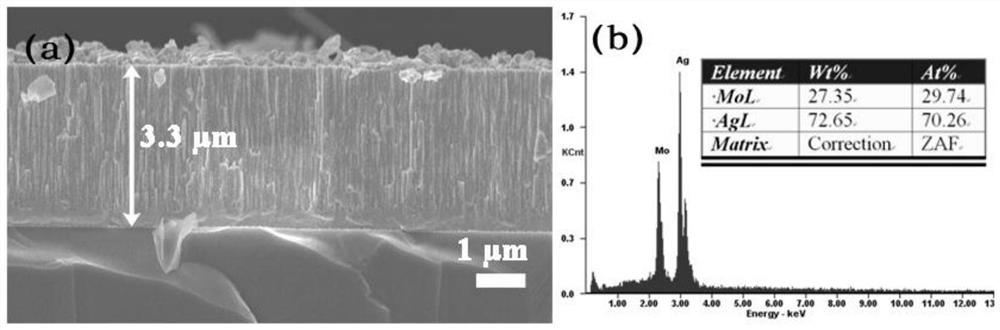

[0066] The Mo that embodiment 3 obtains x Ag y The morphology of the alloy thin film is as image 3 As shown in (a), its energy spectrum is as image 3 (b) shown. X-ray diffraction analysis of samples, such as image 3 As shown in (c), due to the equivalent content of the two elements in the film sample, the solid solution causes the shift and broadening of the peak position, and the peak division shows that the diffraction peak is composed of pure silver, Mo(Ag) solid solution and pure amorphous molybdenum.

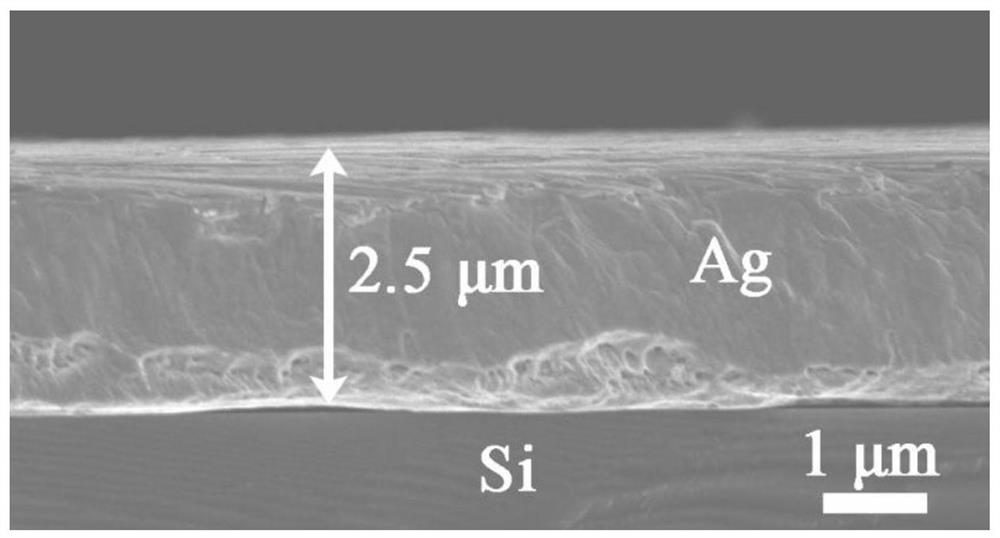

[0067] For the Mo obtained in Example 5 x Ag y The alloy film was analyzed by transmission electron microscope, energy spectrum analysis and X-ray diffraction analysis, the results are as follows Figure 5 (a), (b), (c), (d), as shown in Figure 5 As shown in (c), the silver and molybdenum in the film are mixed evenly. Due to the high silver content, there is a tendency to form a layered structure. It is found in the SEM image that there are a large number of part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com