Heating Rod for Critical Heat Flux Test

A critical heat flux density and test technology, applied in the field of nuclear reactor test research, can solve the problems of inability to achieve rapid and large heat exchange, large diameter of electric heating rods, and inability to process and assemble, and achieve precise control of effective heating length, accurate size and rapidity The effect of a large amount of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

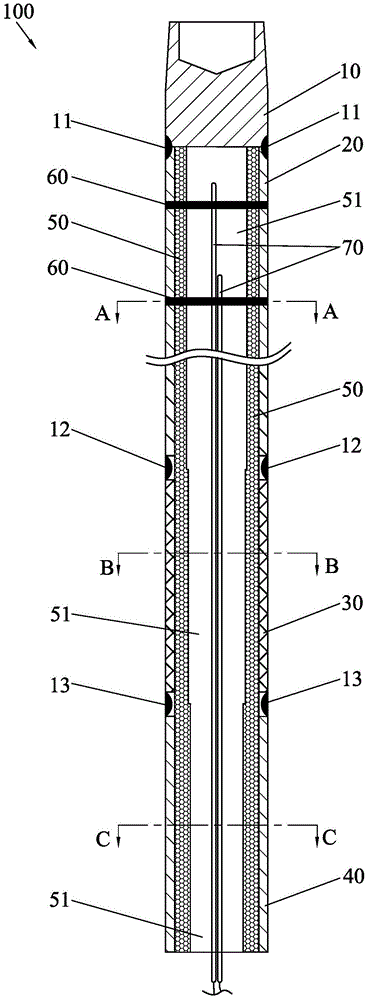

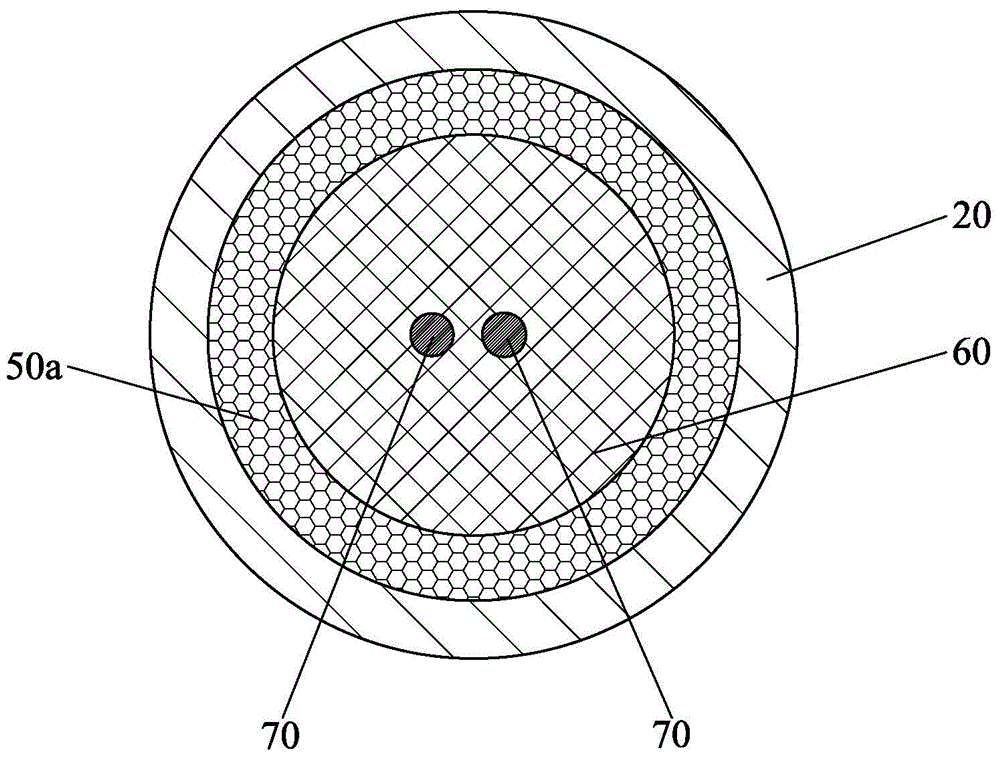

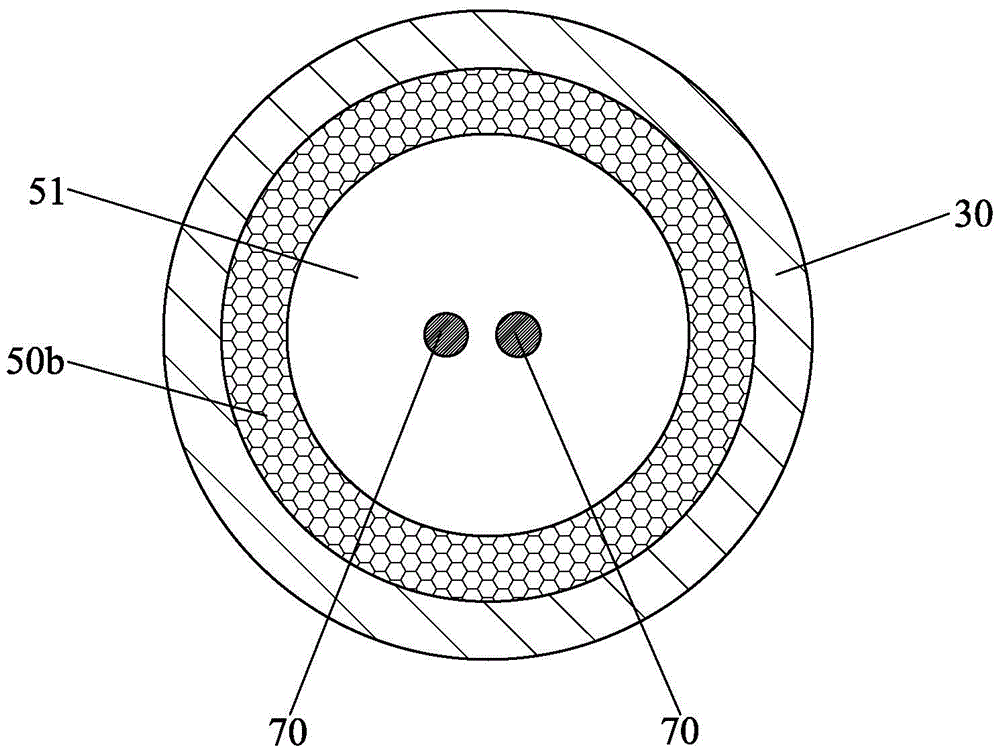

[0021] Such as figure 1 As shown, the heating rod 100 for the critical heat flux test of the present invention is used to simulate the heat release of nuclear fuel and carry out the critical heat flux test, which includes a nickel rod 10, a heating tube 20, a nickel tube 30, a copper tube 40, a ceramic part 50, Copper sheet 60 and thermocouple 70, the upper end of the nickel rod 10 is connected to the external upper live equipment, the lower end of the nickel rod 10 is docked with the upper end of the heating tube 20 and sealed and fixedly connected, and the nickel rod 10 is used for heating The pipe 20 is docked and fixed to ensure the strength while reducing the ineffective calorific value; the lower end of the heating pipe 20 is docked with the upper end of the nickel pipe 30 and sealed and fixedly connected, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com