Liupao tea drying method

A drying method, the technology of Liubao tea, which is applied in the field of Liubao tea drying and drying tea, can solve the problems of high processing cost and high energy consumption, and achieve the effects of reducing processing cost, reducing damage and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The tea steaming method of Benliubao tea comprises the following steps:

[0018] A. Loosen the fermented Liubao tea heap to form tea leaves, spray 0.2% fermented liquid by weight of the tea heap and stir evenly, place it for 48 hours, put it into a tea dryer for drying.

[0019] The fermented liquid is made according to the following steps: add water and brown sugar to the remaining raw tea after screening, mix, and ferment the liquid filtered out after 6 months; the ratio of the remaining raw tea, water and brown sugar is 2.5:10:1.

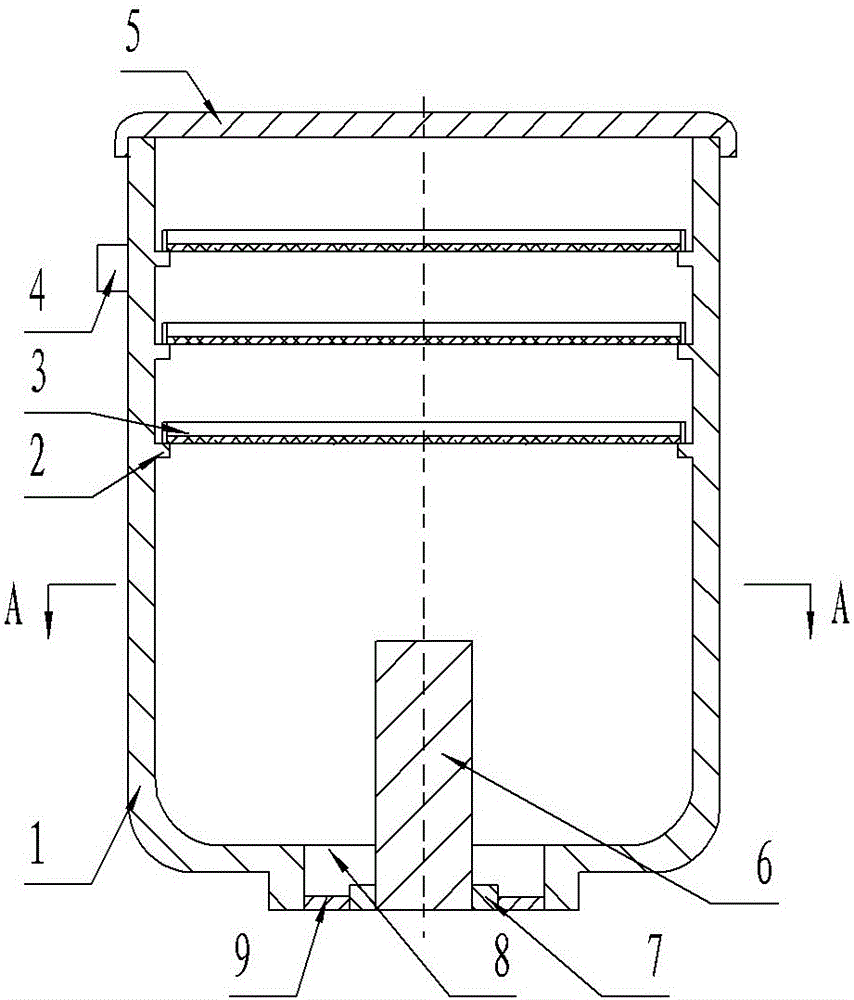

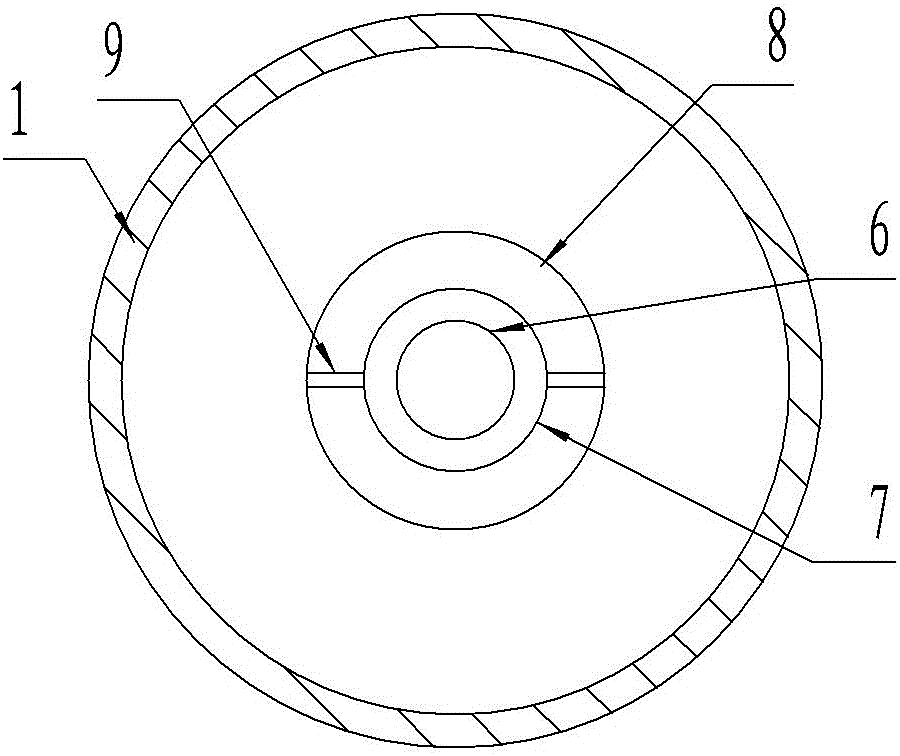

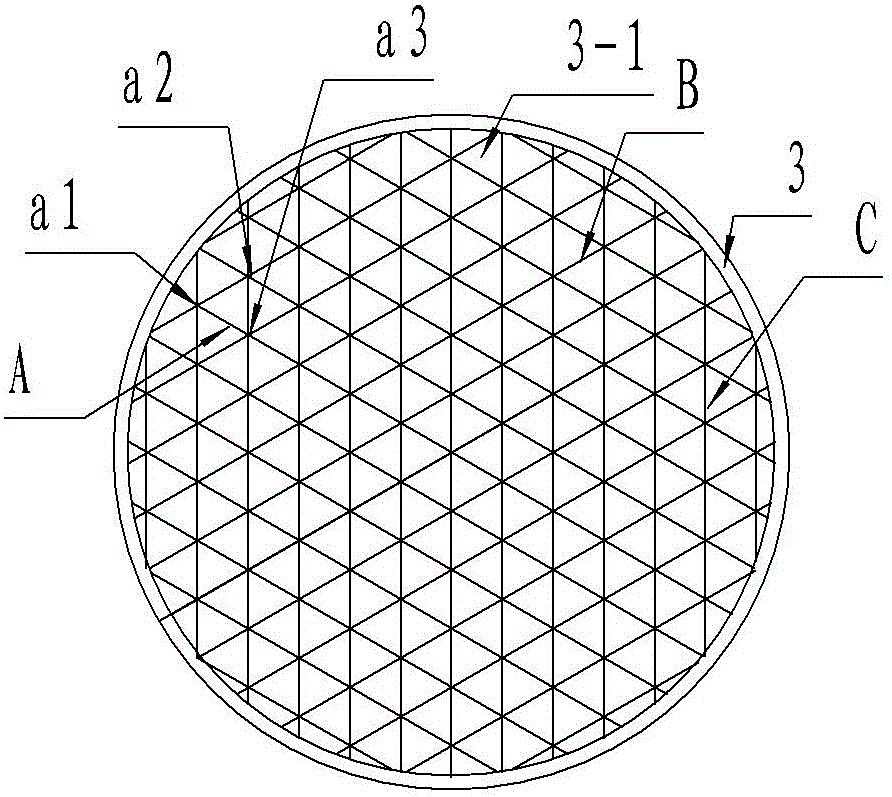

[0020] tea dryer figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a metal cylinder 1 and a metal cylinder cover 5, an opening 8 is provided at the bottom of the cylinder 1, a metal vertical shaft 6 is erected at the opening 8, and a metal electrode ring 7 is provided at the bottom of the vertical shaft 6. , There is a gap between the bottom opening 8 of the cylinder 1 and the electrode ring 7 of the vertical shaft 6, a...

Embodiment 2

[0024] The tea steaming method of Benliubao tea comprises the following steps:

[0025] A. Loosen the fermented Liubao tea heap to form tea leaves, spray 0.3% fermented liquid by weight of the tea heap and stir evenly, place it for 48 hours, put it into a tea dryer for drying.

[0026] The fermented liquid is made according to the following steps: add water and black sugar to the remaining raw tea after screening, mix, and ferment the liquid filtered out after 6 months; the ratio of the remaining raw tea, water and brown sugar is 2.8:10:1.

[0027] The structure of the tea steaming machine is as in embodiment one.

[0028] The drying steps include: put the tea leaves on the screen 3, put them into the barrel 1, start the power of the electrode, keep it for 1 minute when the temperature in the barrel reaches 90°C, turn off the power, stir for 3 minutes, and then turn on the electrode Turn off the power after 1 minute, stir for 3 minutes, and then turn on the power of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com