A high-efficiency screw rod cleaning and drying machine

An integrated machine and screw technology, applied in the field of screw and standard parts, can solve the problems of easily damaged screw thread, unfavorable cleaning device, poor cleaning effect, etc., to achieve less collision, improve cleaning efficiency, and increase the number of usable times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

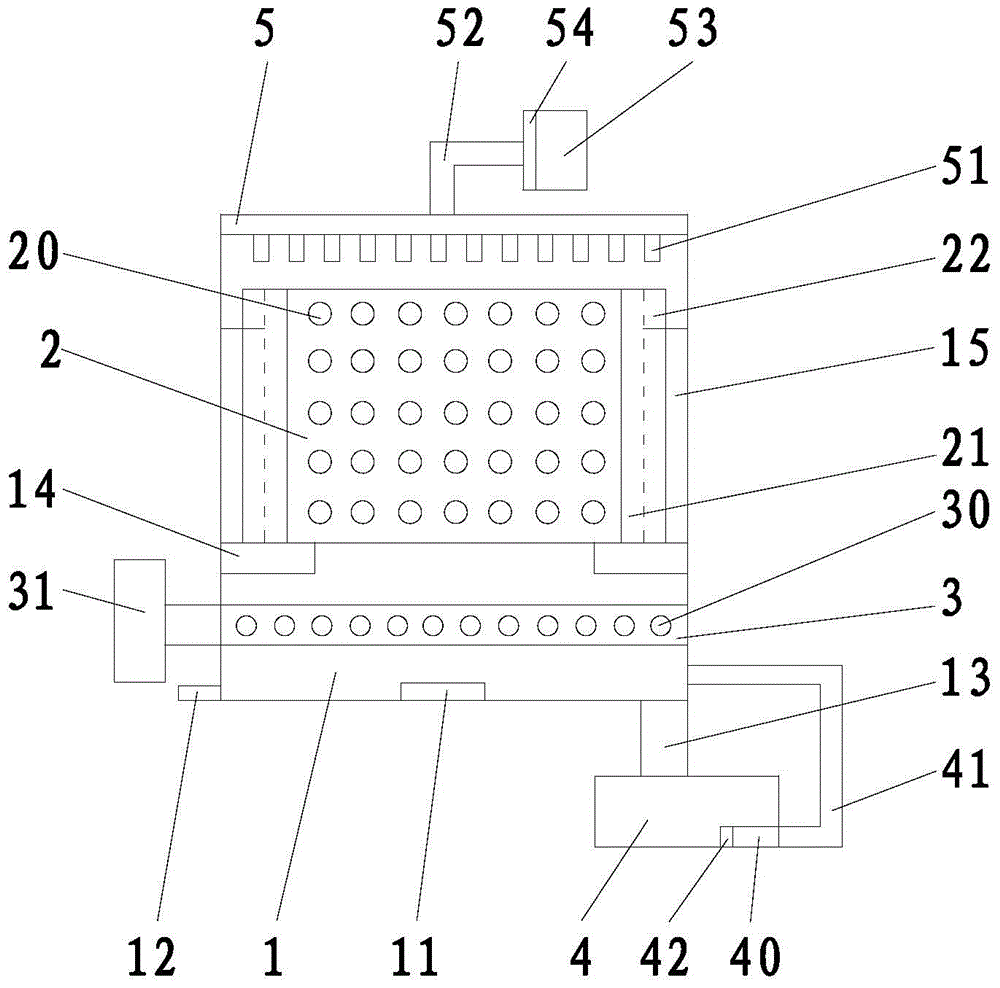

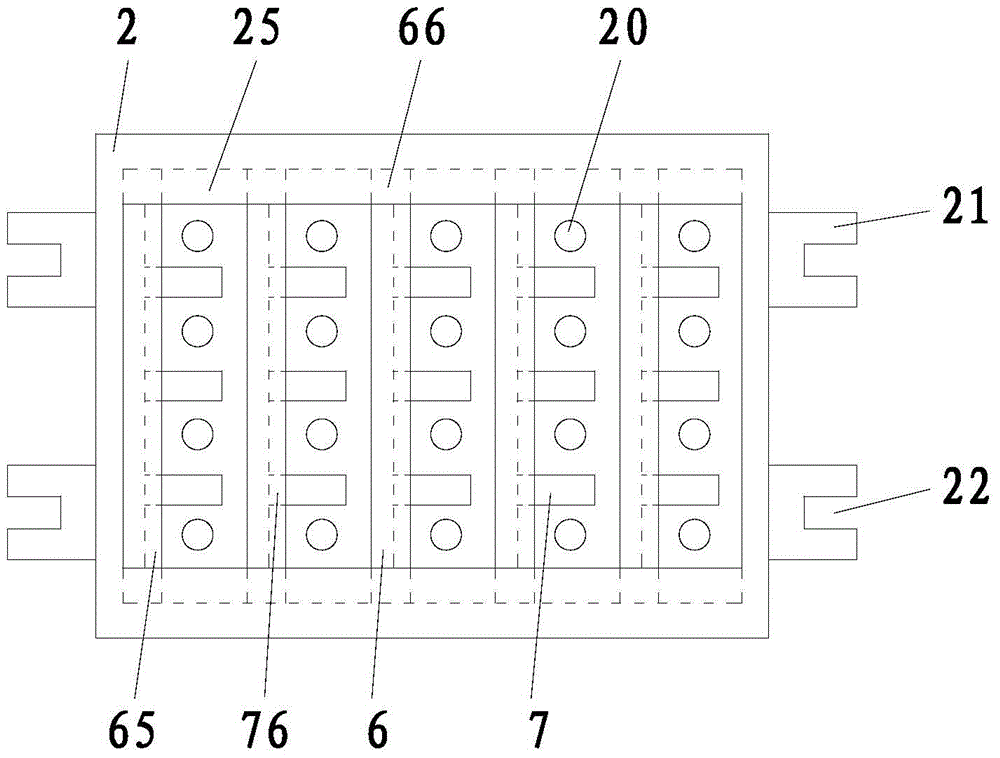

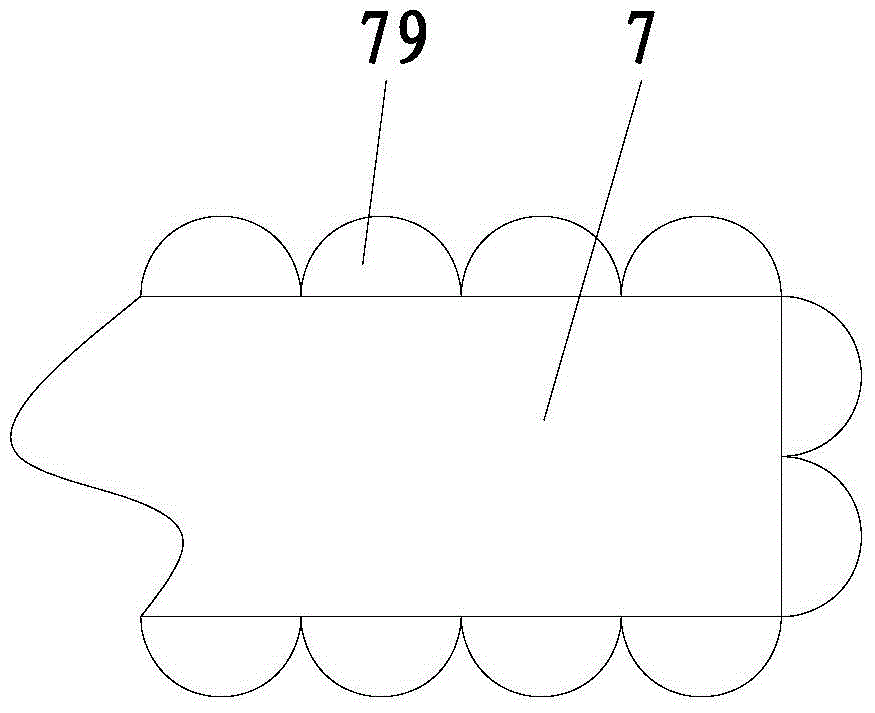

[0021] refer to figure 1 , figure 2 with image 3 , a high-efficiency screw cleaning and drying all-in-one machine of the present invention, comprising a box body 1 and a material holding frame 2, an ultrasonic generator 11, a liquid discharge pipe 12 and a liquid outlet pipe 13 are installed at the bottom of the box body 1, and the box body 1 There is a liquid storage tank 4 below, and the liquid outlet pipe 13 is connected with the liquid storage tank 4. There is a liquid suction pump 40 in the liquid storage tank 4. The liquid suction pump 40 is connected with a return pipe 41. The air outlet pipe 3 is installed in the box body 1, one end of the air outlet pipe 3 is sealed, the unsealed end of the air outlet pipe 3 is outside the box body 1, the unsealed end of the air outlet pipe 3 is connected with a blower 31, and the air outlet pipe 3 inside the box body 1 A plurality of air outlet holes 30 are arranged on the body of the pipe, and a retaining ring 14 is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com