Protection door used for numerical control lathe and provided with mobile terminal control system

A mobile terminal, CNC lathe technology, applied in transmission systems, turning equipment, manufacturing tools, etc., can solve the problems of complicated correspondence between keys and locks, uncertainty of safety hazards of protective doors, long outage intervals, etc. To unlock the matching process, prolong the effective working time, and improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

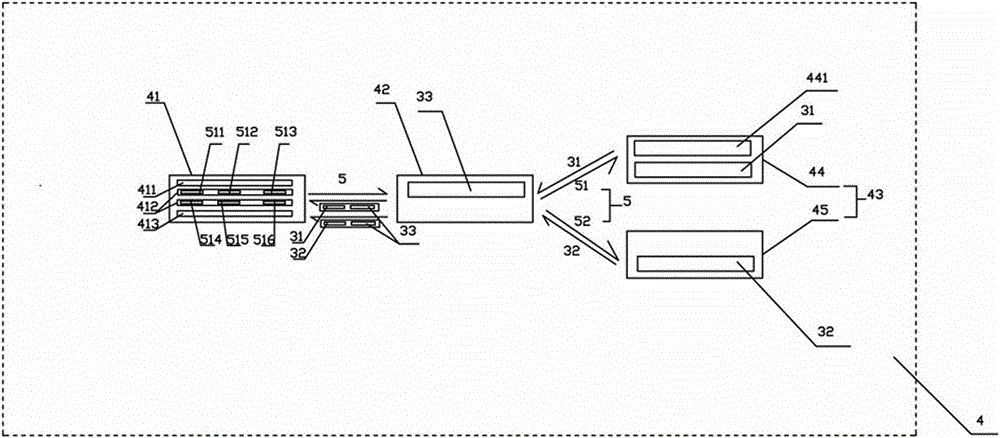

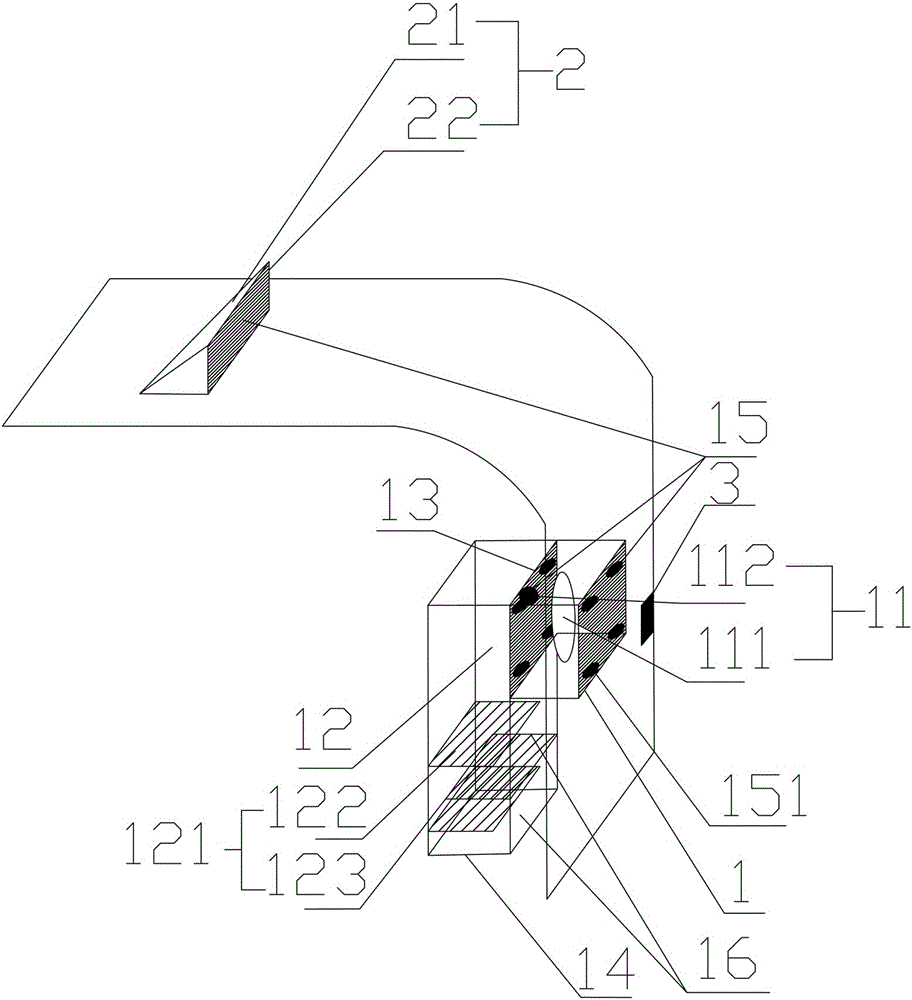

[0019] like figure 1 and figure 2As shown, it is a protective door of a numerically controlled lathe equipped with a mobile terminal control system according to the present invention. The protective door is slidably arranged on the numerically controlled lathe through slide rails and chutes. It is characterized in that: the protective door includes a fan cabin 1 and a ventilation cabin 2 , door lock 3 and mobile terminal control system 4, the mobile terminal control system 4 includes a host computer 41, a mobile terminal 42 and a controller 43 connected successively through the mobile terminal communication network, and the controller 43 includes a door lock controller 44 and a drive motor control device 45, the fan cabin 1, the ventilation cabin 2 and the door lock 3 are all arranged on the protective door; the fan cabin 1 includes a fan la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com