Moving method of carbon dioxide gas cylinders for pile splicing welding along with pile machine

A carbon dioxide, pile-joining welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of unsafe and inconvenient dragging, high physical labor intensity, inconvenience, etc., and achieve convenient and free operation and walking. The effect of reducing labor intensity and improving piling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The method for moving the carbon dioxide cylinder with the pile driver for pile welding of the present invention is characterized in that it comprises the following steps:

[0023] a. Make U-shaped ring sleeve

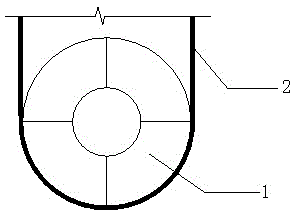

[0024] see now figure 1 , figure 1 It is a structural schematic diagram of the U-shaped ring sleeve of the carbon dioxide cylinder according to the embodiment of the present invention. As shown in the figure, the U-shaped ring sleeve 2 is made of round steel with a diameter of 10mm bent into a semicircular arc, and the diameter of the arc is 4mm larger than the diameter of the carbon dioxide cylinder;

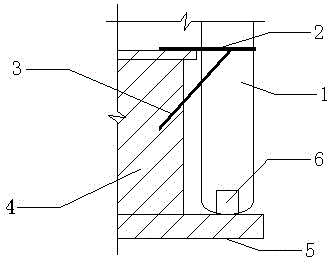

[0025] b. Install U-shaped ring sleeve 2 on the pile driver base

[0026] Two U-shaped ring sleeves 2 are respectively adjacently installed on the two sides of the pile driver 4; the two ends of each U-shaped ring sleeve are welded to the upper flange of the section steel of the pile driver base, and round steel rings are used on both sides of the U-shaped rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com