Welding fixture for nuclear fuel assembly positioning grillwork

A technology for nuclear fuel components and welding fixtures, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve problems such as poor design accuracy, affecting welding quality, and cumbersome welding fixture structure, so as to improve welding quality, easy processing, prevent loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

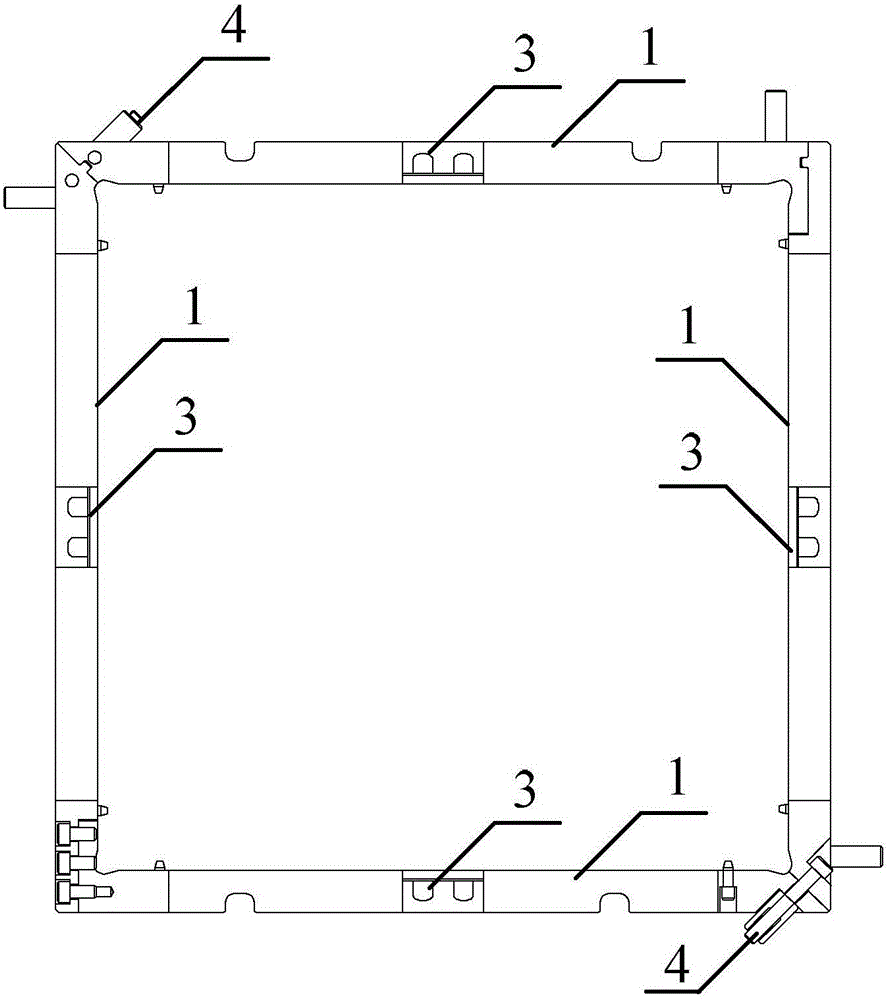

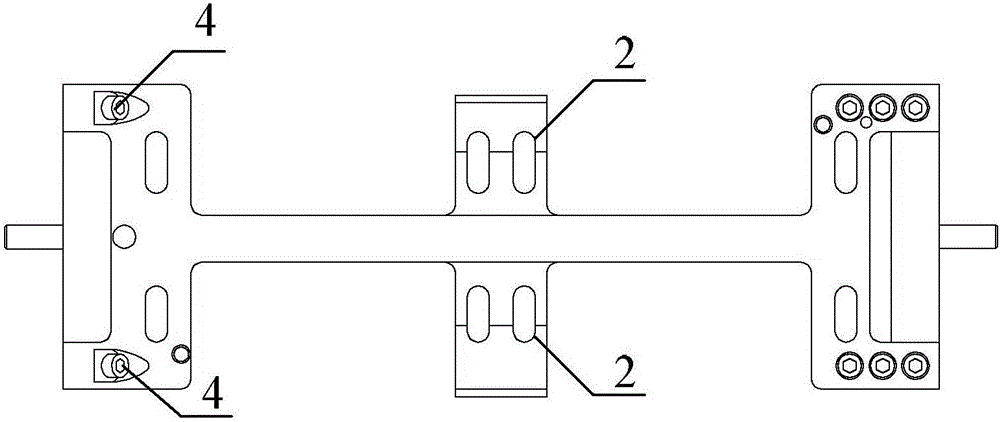

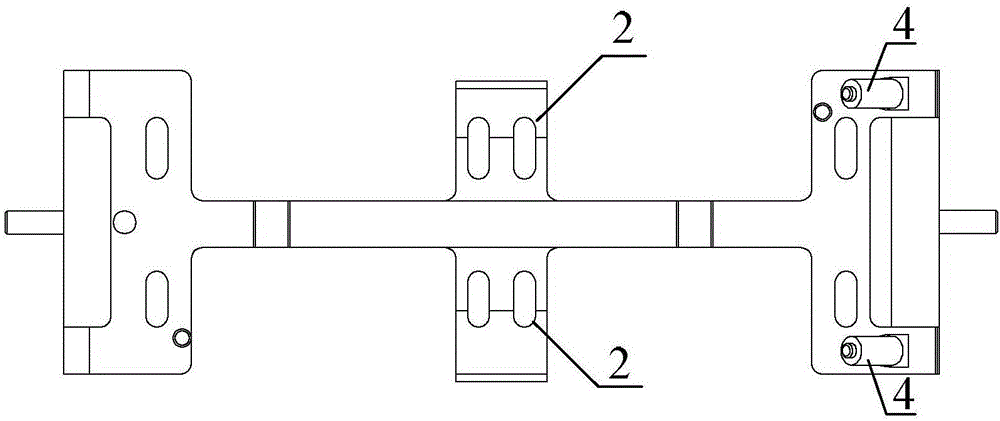

[0016] Specific implementation mode one: combine Figures 1 to 5 To illustrate this embodiment, the welding fixture used for the positioning grid of nuclear fuel assemblies described in this embodiment includes a traveling fixture and a casing fixture;

[0017] The accompanying fixture includes four positioning plates 1, and the four positioning plates 1 surround a square frame, and the length and width of the square area inside the square frame can be adjusted, and each positioning plate 1 is provided with two rows of light-through holes 2, and each positioning plate 1 is provided with a positioning pin 3;

[0018] The casing fixture includes an upper cover plate and a bottom plate, and a through hole 5 is opened on the bottom plate corresponding to the casing pipe, and a plum blossom hole 6 is opened on the upper cover plate corresponding to the casing pipe, and four holes are installed around the plum blossom hole 6. There are four protrusions distributed symmetrically.

...

specific Embodiment approach 2

[0032] Specific Embodiment 2: This embodiment is a further limitation of the welding jig for the nuclear fuel assembly positioning grid described in Embodiment 1. In this embodiment, the inner surfaces of the upper cover plate and the bottom plate are provided with inner strips Groove for point-by-point positioning over the full length.

[0033] The inner surfaces of the upper cover and the bottom plate are provided with grooves for point-by-point positioning of the vertical and horizontal inner strips. The strips in the grid are inserted into the positioning grooves of the bottom plate of the fixture for overall positioning, and the two-dimensional positioning of the grid plane is completed.

[0034] Specific implementation method three: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the welding fixture used for the positioning grid of nuclear fuel assemblies described in Embodiment 1. In this embodiment, the inner surfaces of the up...

specific Embodiment approach 4

[0036] Specific implementation mode four: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the welding jig used for the positioning grid of nuclear fuel assemblies described in Embodiments 1 and 2. Wire.

[0037] Observe the welding process through the CCD camera of the laser welding head. If there is a deviation between the engraved line and the coordinate track of the motion system, control the laser three-dimensional motion mechanism to align the cross mark on the CCD monitor with the starting point and end point of the engraved line on the welding fixture. The system can automatically complete the deviation correction to further improve the welding accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com