Assembling method of soil breaking and deep rotary tillage machine

An assembly method and powder ridge machine technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, large volume, inconvenient, etc., and achieve the purpose of improving locking force, expanding volume, increasing strength and The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

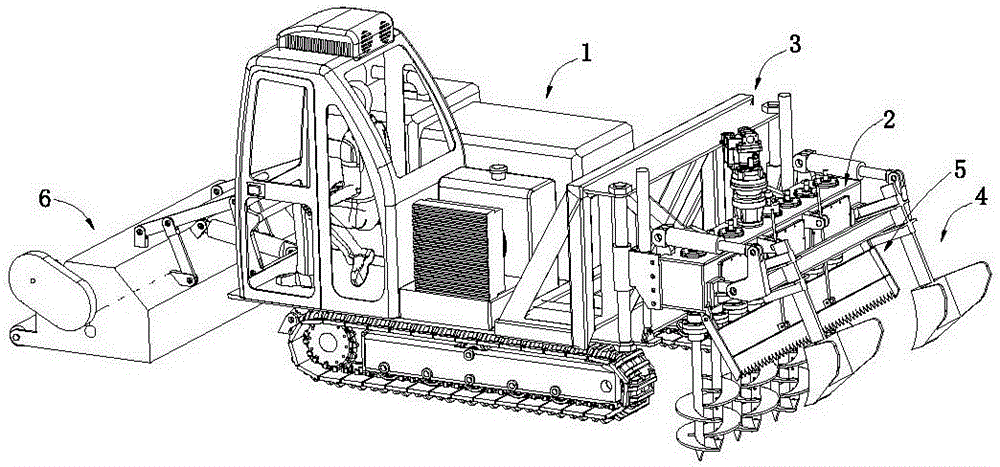

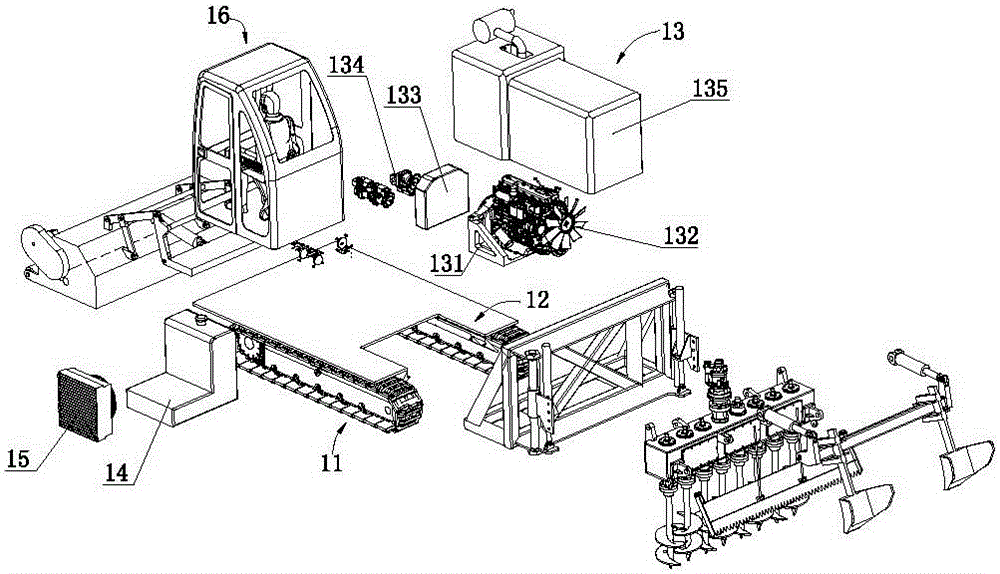

[0081] Such as figure 1 and figure 2 As shown, the plowing powder ridge machine includes a body 1 , a powder ridge device 2 , a connecting device 3 , a ditching device 4 , a leveling device 5 and a straw returning device 6 .

[0082] Such as figure 2 As shown, the body 1 includes a traveling mechanism 11 , a frame 12 , a diesel engine assembly 13 , a hydraulic oil tank 14 , a cooler 15 and a cab 16 .

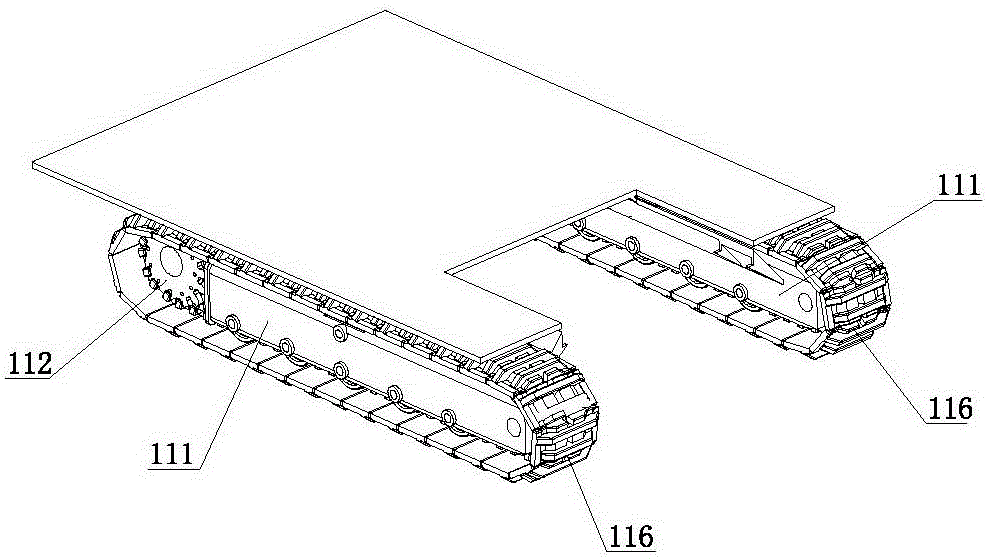

[0083] Such as Figure 3 to Figure 8 As shown, the running mechanism 11 includes two opposite crawler belt assemblies, and the crawler belt assembly includes a wheel frame 111, a driving wheel 112, a driven wheel 113, a lower guide wheel 114, an upper guide wheel 115, a crawler belt 116 and a travel drive.

[0084] Such as Figure 7 and Figure 8 As shown, the wheel frame 111 includes a wheel frame body 1111 and a wheel frame co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com