A device for self-separation of gas and liquid and a method for self-separation of gas and liquid

A gas-liquid separation and generating device technology, which is applied in the direction of chlorine oxidation, oxidized water/sewage treatment, etc., can solve the problems of waste of chlorine dioxide gas, increase of floor area, increase of equipment investment, etc., to achieve increased floor area, The effect of reducing investment cost and increasing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

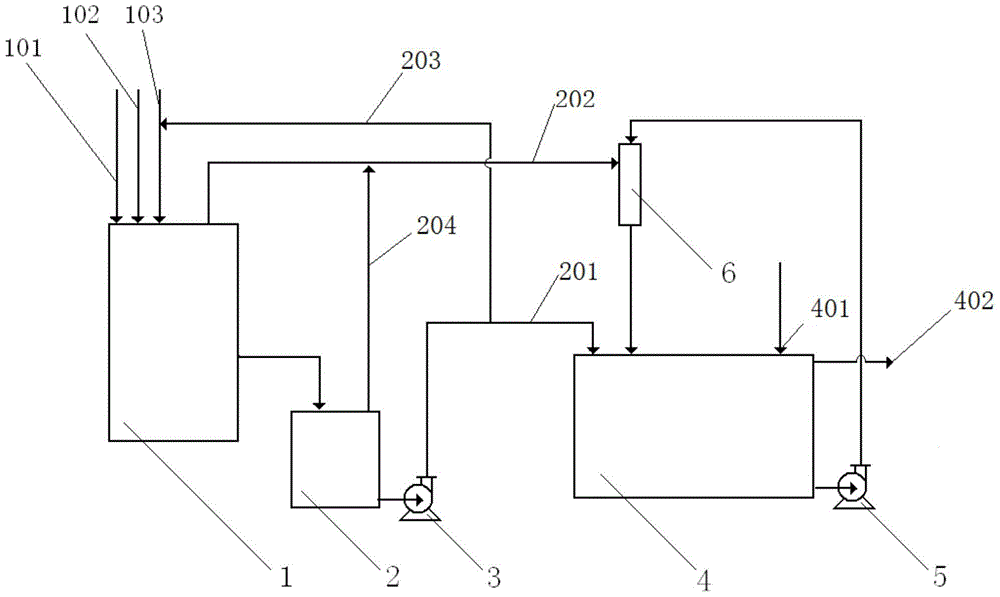

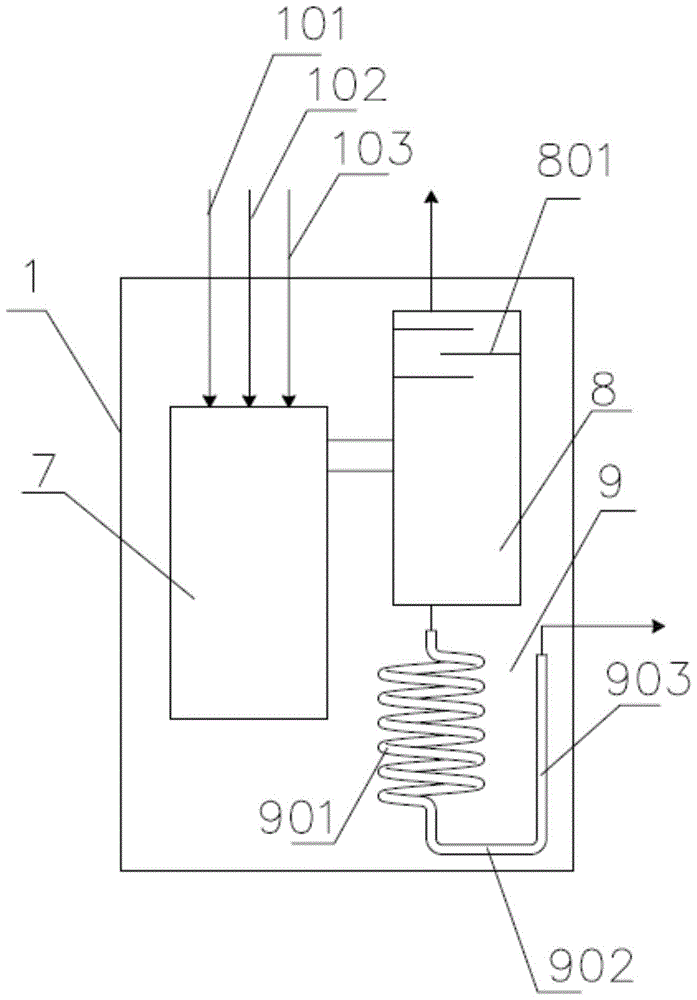

[0025] Such as Figure 1-Figure 3 As shown, a self-gas-liquid separation device includes a high-purity chlorine dioxide generator 1, a raffinate storage tank 2, a raffinate pump 3, a waste water treatment tank 4, a circulation pump 5 and a water ejector 6 connected in series in sequence. The high-purity chlorine dioxide generator 1 includes a chlorine dioxide generator 7 , a buffer tank 8 and special-shaped U-shaped pipes 9 connected in sequence.

[0026] On this basis, preferably: the raffinate pump 3 is connected to the waste water treatment tank 4 through the first pipeline 201, the water injector 6 is connected to the waste water treatment tank 4, and the water injector 6 is also connected through the second pipeline 202 It is connected with the high-purity chlorine dioxide generator 1, and the chlorine dioxide generator 7 in the high-purity chlorine dioxide generator 1 is connected with the raw material input pipeline, and the third pipe is passed between the raw material...

Embodiment 2

[0033] A method for self-separation of gas-liquid by using the device for self-separation of gas-liquid in embodiment 1, comprising the steps of:

[0034] The high-purity chlorine dioxide generator 1 controls the temperature through the electromagnetic induction heater, and controls the negative pressure through the water injector 6, and the chlorine dioxide gas and the residual liquid after the reaction produced by the reaction are respectively placed in the high-purity chlorine dioxide generator 1. The upper and lower parts are self-separated, wherein, in the upper part of the high-purity chlorine dioxide generator 1, the pure chlorine dioxide gas is separated by the buffer tank 8, and then directly pumped out by the water injector 6 and sent to the water body to be treated. The lower part of the chlorine dioxide generator 1, after the reaction, the residual liquid passes through the special-shaped U-shaped pipe 9, and the residual liquid is separated by the change of pressur...

Embodiment 3

[0037] A kind of method adopting the device described in embodiment 1 to carry out automatic gas-liquid separation, comprises the steps:

[0038] The high-purity chlorine dioxide generator 1 is controlled at 56°C by an electromagnetic induction heater, and the high-purity chlorine dioxide produced by the reaction passes through the buffer tank 8 on the upper part of the high-purity chlorine dioxide generator 1 at a gas velocity ratio of 76:1. Next, pure chlorine dioxide gas is obtained, and the chlorine dioxide gas from the residual liquid storage tank 2 is sent to the water body to be treated through the water injector 6; the residual liquid produced after the reaction passes through the special-shaped chlorine dioxide generator 1 bottom U-shaped pipe 9, the negative pressure in the control pipe is >9.5KPa, the separated raffinate flows into the raffinate storage tank 2 by itself, and is sent to the waste water treatment pool 4 or the chlorine dioxide generator 1 through the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com