Expanded graphite and graphene composite material and preparation method therefor

A technology of expanded graphite and composite materials, used in ceramic products, other household appliances, household appliances, etc., can solve the problems of lack of resilience, limited application scope, strict equipment requirements, etc., and achieve the effect of improving resilience performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

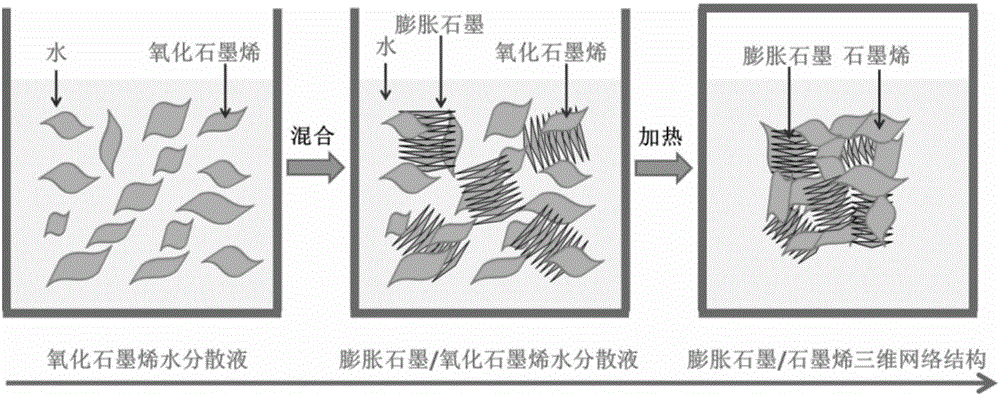

Method used

Image

Examples

Embodiment 1

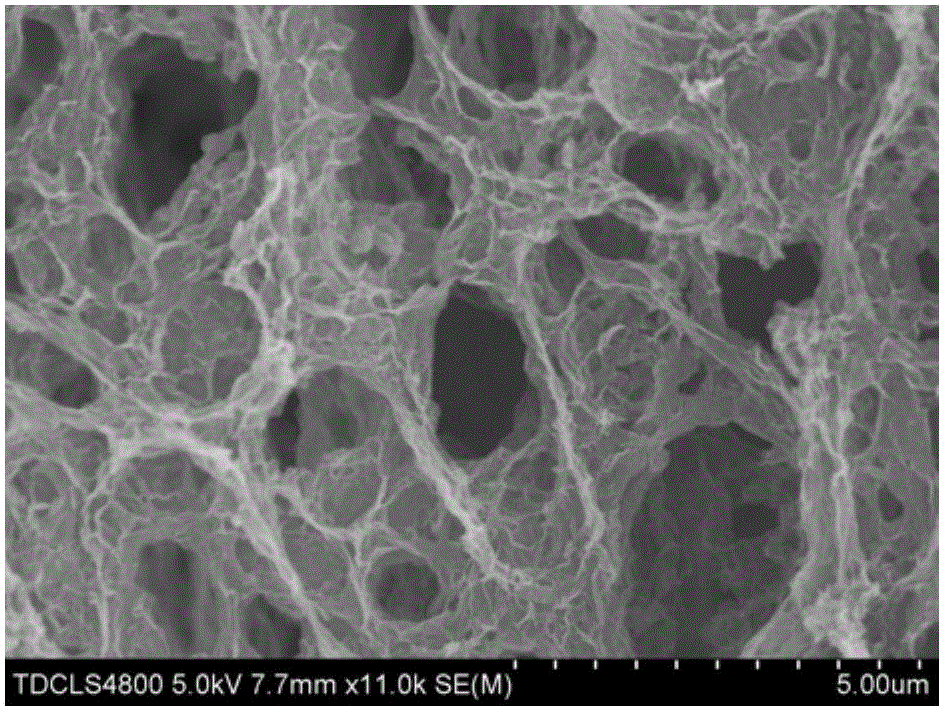

[0029] Prepare 100 g of graphene oxide aqueous dispersion with a mass fraction of 0.1%, weigh 1 g of 100-mesh expanded graphite and add the above-mentioned graphene oxide aqueous dispersion, stir and mix evenly to obtain expanded graphite / graphene oxide aqueous dispersion, and place it in an airtight Then place it in a muffle furnace for heat treatment at 120°C for 24 hours, take out the sample after cooling down, and obtain expanded graphite / graphene-based carbon foam after drying, which is a composite material of expanded graphite and graphene. Its thermal conductivity and rebound performance were tested respectively. Its thermal conductivity is 55W / (m·K), and it is compressed 100 times at a compression rate of 70%, and its rebound rate is 90%.

Embodiment 2

[0031]Prepare 100 g of graphene oxide aqueous dispersion with a mass fraction of 10%, weigh 1 g of 300-mesh expanded graphite and add it to the above-mentioned graphene oxide aqueous dispersion, stir and mix evenly to obtain expanded graphite / graphene oxide aqueous dispersion, and place it in an airtight The container is then placed in a muffle furnace for heat treatment at 260°C for 24 hours, and the sample is taken out after cooling down, and the expanded graphite / graphene-based carbon foam is obtained after drying, which is a composite material of expanded graphite and graphene. Its thermal conductivity and rebound performance were tested respectively. Its thermal conductivity is 100W / (m·K), and it is compressed 100 times at a compression rate of 70%, and its rebound rate is 96%.

Embodiment 3

[0033] Prepare 100 g of graphene oxide aqueous dispersion with a mass fraction of 10%, weigh 10 g of 200-mesh expanded graphite and add the above-mentioned graphene oxide aqueous dispersion, stir and mix uniformly to obtain expanded graphite / graphene oxide aqueous dispersion, place it in an airtight The container is then placed in a muffle furnace for heat treatment at 180°C for 12 hours, and the sample is taken out after cooling down, and the expanded graphite / graphene-based carbon foam is obtained after drying, which is a composite material of expanded graphite and graphene. Its thermal conductivity and rebound performance were tested respectively. Its thermal conductivity is 90W / (m·K), and it is compressed 100 times at a compression rate of 70%, and its rebound rate is 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com