Soil curing method for saline and alkaline land by using polyvinyl alcohol soil scarification agent

A technology for deep soil loosening and soil maturation, applied in the field of saline-alkali land maturation, can solve the problems of large soil volume, low total soil porosity in saline-alkali land, lowering pH value of saline-alkali land, etc., so as to improve soil organic matter content and humus content, and increase soil total porosity. the effect of improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

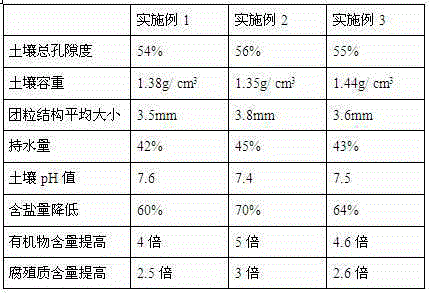

Embodiment 1

[0026] Embodiment 1 A kind of polyvinyl alcohol soil loosening agent

[0027] The weight ratio of each component of the soil subsoiling agent is:

[0028] 7 parts of polyvinyl alcohol, 2 parts of Bacillus licheniformis bacteria liquid, 12 parts of potato flour, 8 parts of modified starch, 6 parts of vermiculite, 14 parts of medical stone, 5 parts of ferrous ammonium sulfate, 2.5 parts of carboxymethyl cellulose , 4 parts of raw gypsum, 6 parts of humic acid;

[0029] The modified starch includes 60% acrylic acid modified starch and 40% acetic acid modified starch, and the percentages are all percentages by weight.

Embodiment 2

[0030] Embodiment 2 A kind of polyvinyl alcohol soil loosening agent

[0031] 8 parts of polyvinyl alcohol, 3 parts of Bacillus licheniformis bacteria liquid, 15 parts of potato flour, 10 parts of modified starch, 7 parts of vermiculite, 15 parts of medical stone, 6 parts of ferrous ammonium sulfate, 3 parts of carboxymethyl cellulose , 5 parts of raw gypsum, 8 parts of humic acid;

[0032] The modified starch includes 60% acrylic acid modified starch and 40% acetic acid modified starch, and the percentages are all percentages by weight.

Embodiment 3

[0033] Example 3 A polyvinyl alcohol soil loosening agent

[0034] 10 parts of polyvinyl alcohol, 4 parts of Bacillus licheniformis bacteria liquid, 19 parts of potato flour, 12 parts of modified starch, 8 parts of vermiculite, 18 parts of medical stone, 7 parts of ferrous ammonium sulfate, 3.5 parts of carboxymethyl cellulose , 7 parts of raw gypsum, 9 parts of humic acid;

[0035] The modified starch includes 60% acrylic acid modified starch and 40% acetic acid modified starch, and the percentages are all percentages by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com