Crystallization regulation system and application of crystallization regulation system in rapid molding of polyformaldehyde panel/bar

A system and crystallization technology, applied in the field of polymer material modification, to achieve the effect of refining grains, accelerating crystallization rate, and inhibiting crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

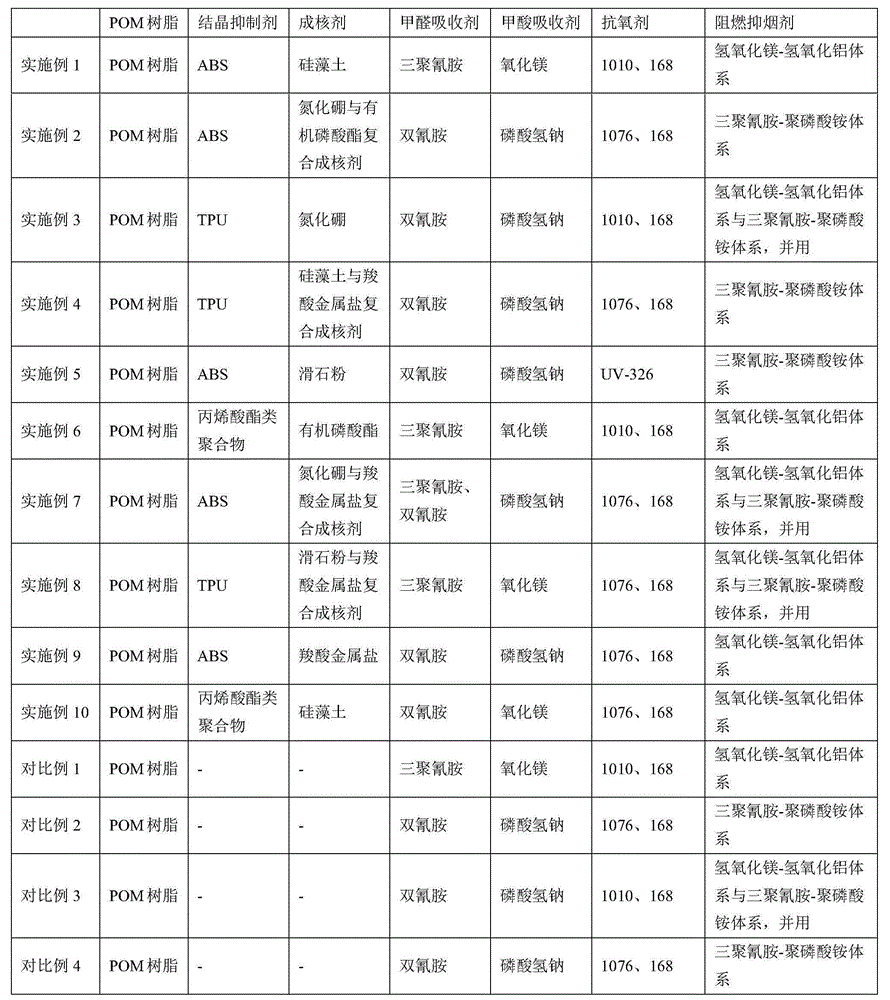

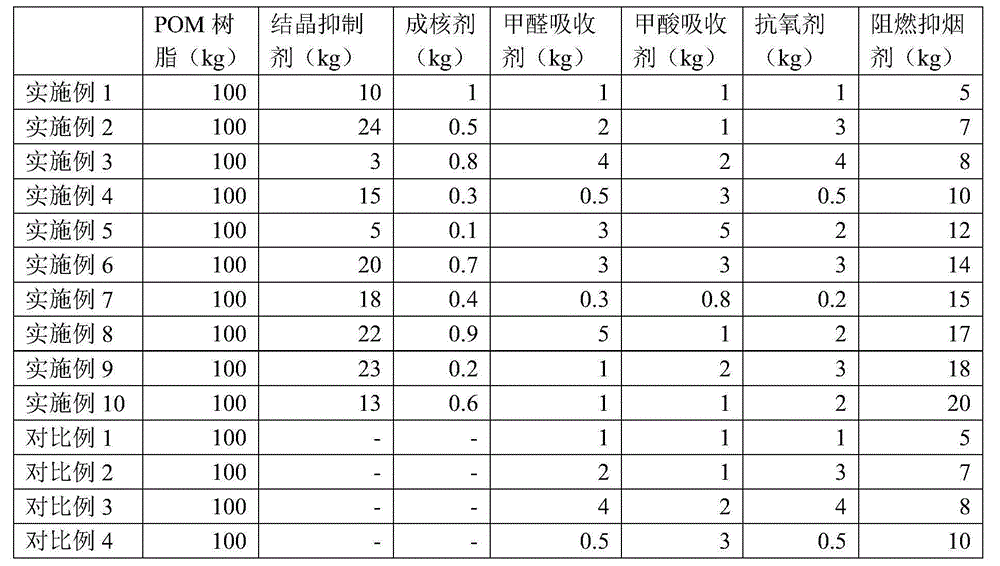

[0037] In the research process of the present invention, repeated tests have been done on the selection and proportioning of materials, and several preferred embodiments are selected below to further describe the present invention in detail, wherein the raw materials used can be obtained through commercial channels.

[0038] Embodiment 1-10 and comparative example 1-4 carry out batching according to Table 1 and Table 2, then prepare according to the following steps: (1) POM resin, crystallization control system, flame retardant and auxiliary agent are put into mixer, adjust The speed of the mixer is 500-1500rpm, the mixing time is 1-2min, all materials are mixed evenly, and the materials are discharged; (2) the raw materials mixed in step (1) are added to the twin-screw extruder, extruded and granulated; the twin-screw The temperature of each section of the extruder: 50-100°C, 185-195°C, 200-210°C, 205-210°C, die: 200-205°C, screw speed: 120-240rpm.

[0039] Table 1 Embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com