Water-based ink, its preparation method and printed matter

A water-based ink and ink technology, used in inks, household appliances, applications, etc., can solve the problems of whitening of structural colors, low hue saturation, loss of structural colors, etc., and achieve the effect of rich color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

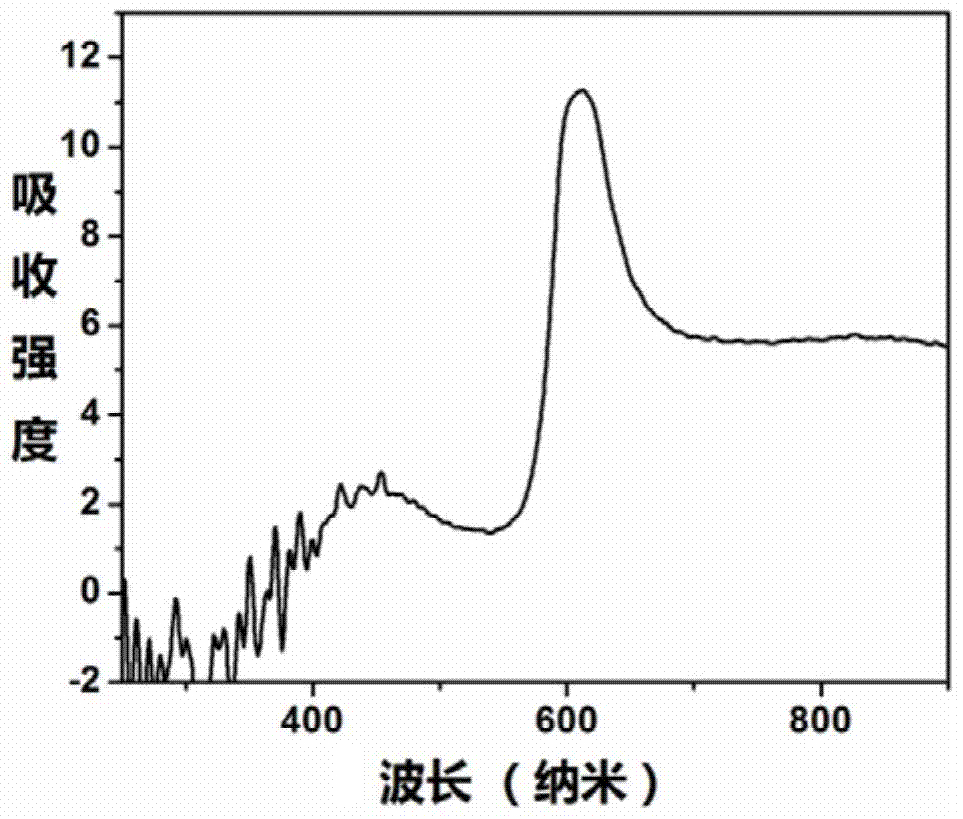

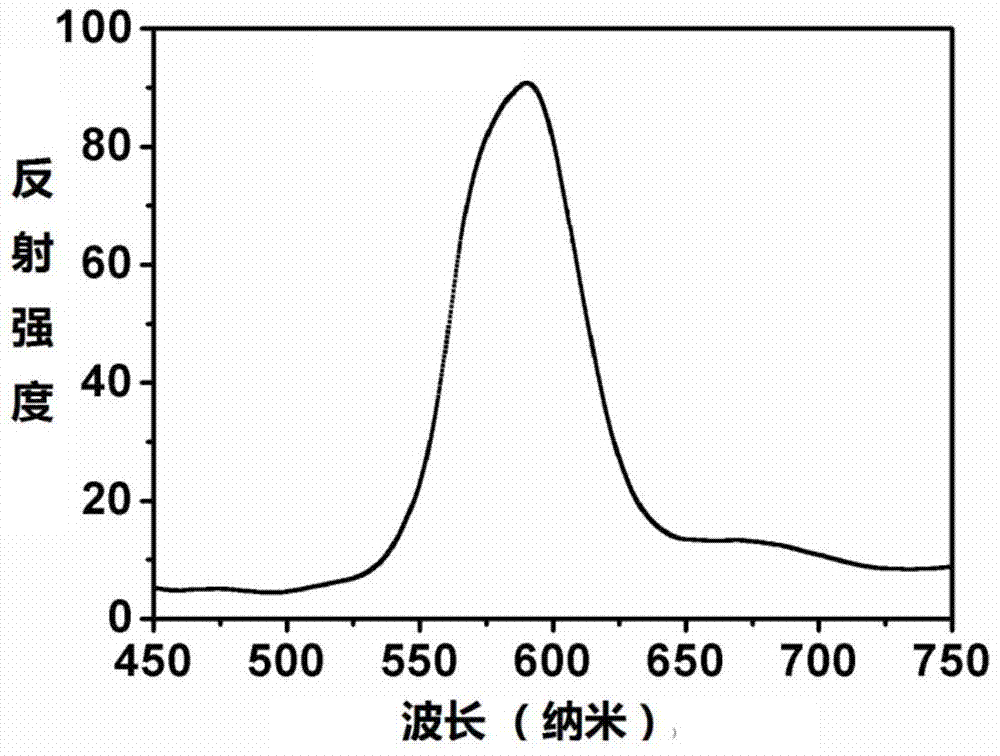

[0039] A kind of preparation method that is used to prepare the water-based ink that has structural color light-changing characteristic print, comprises the following steps:

[0040] a. Add monodisperse styrene microsphere emulsion, water-based acrylic emulsion, and isobutanol into the kettle and stir evenly for 15 minutes;

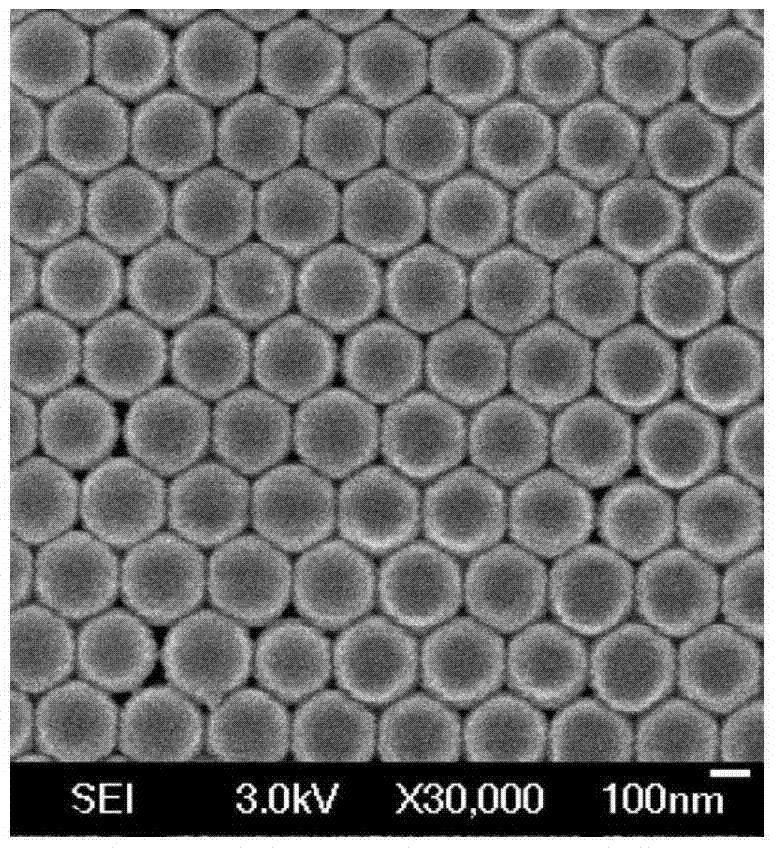

[0041] b. adding silica nanoparticles, iron oxide red pigment, dispersant and defoamer to the material prepared in step a, stirring for 25 minutes; then grinding the stirred material to below 15 microns;

[0042] c. Add a certain weight portion of leveling agent, film-forming aid, and adhesion promoter to the material prepared in step b, stir for 15 minutes to make it evenly mixed, and prepare the ink;

[0043]Wherein, the parts by weight of each raw material are: particle diameter is 55 parts of styrene emulsions of 270 nanometers (solid content 60%, PDI is 0.03), 15 parts of acrylic acid emulsions (solid content 20%), silicon dioxide 13 parts (particle ...

Embodiment 2

[0049] A kind of preparation method that is used to prepare the water-based ink that has structural color light-changing characteristic print, comprises the following steps:

[0050] a. Add monodisperse styrene microsphere emulsion, water-based acrylic acid emulsion, and isobutanol into the kettle and stir evenly for 10 minutes;

[0051] b. adding titanium dioxide nanoparticles, iron oxide red pigment, dispersant and defoamer to the material prepared in step a, stirring for 20 minutes; then grinding the stirred material to below 15 microns;

[0052] c. Add certain parts by weight of leveling agent, film-forming aid and adhesion promoter to the material prepared in step b, stir for 20 minutes to make it evenly mixed, and prepare the ink.

[0053] Wherein, the parts by weight of each raw material are: particle diameter is 47 parts of styrene microsphere emulsion (solid content 20%, PDI is 0.02), particle diameter is 190 nanometers, 15 parts of acrylic acid emulsion (solid conten...

Embodiment 3

[0059] A kind of preparation method that is used to prepare the water-based ink that has structural color light-changing characteristic print, comprises the following steps:

[0060] a. Add monodisperse styrene microsphere emulsion, water-based polyurethane emulsion, and n-butanol into the kettle and stir evenly, and the stirring time is 17 minutes;

[0061] b. adding zinc oxide nanoparticles, phthalocyanine green pigment, dispersant and defoamer to the material prepared in step a, stirring for 15 minutes; then grinding the stirred material to below 15 microns;

[0062] c. Add certain parts by weight of leveling agent, film-forming aid, and adhesion promoter to the material prepared in step b, stir for 17 minutes to make it evenly mixed, and prepare the ink.

[0063] Wherein, the parts by weight of each raw material are: particle diameter is 60 parts of styrene emulsions of 210 nanometers (solid content 40%, PDI is 0.02), water-based polyurethane emulsion 13 parts (solid conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com