Multifunctional high pressure gas safety purifier

A high-pressure gas and purifier technology, applied in the direction of gas fuel, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of narrow internal space, difficult to see the operation, not fully applicable, etc., to reduce the probability of deformation or damage , solve the safety hazards of misoperation, and solve the effect of insufficient internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

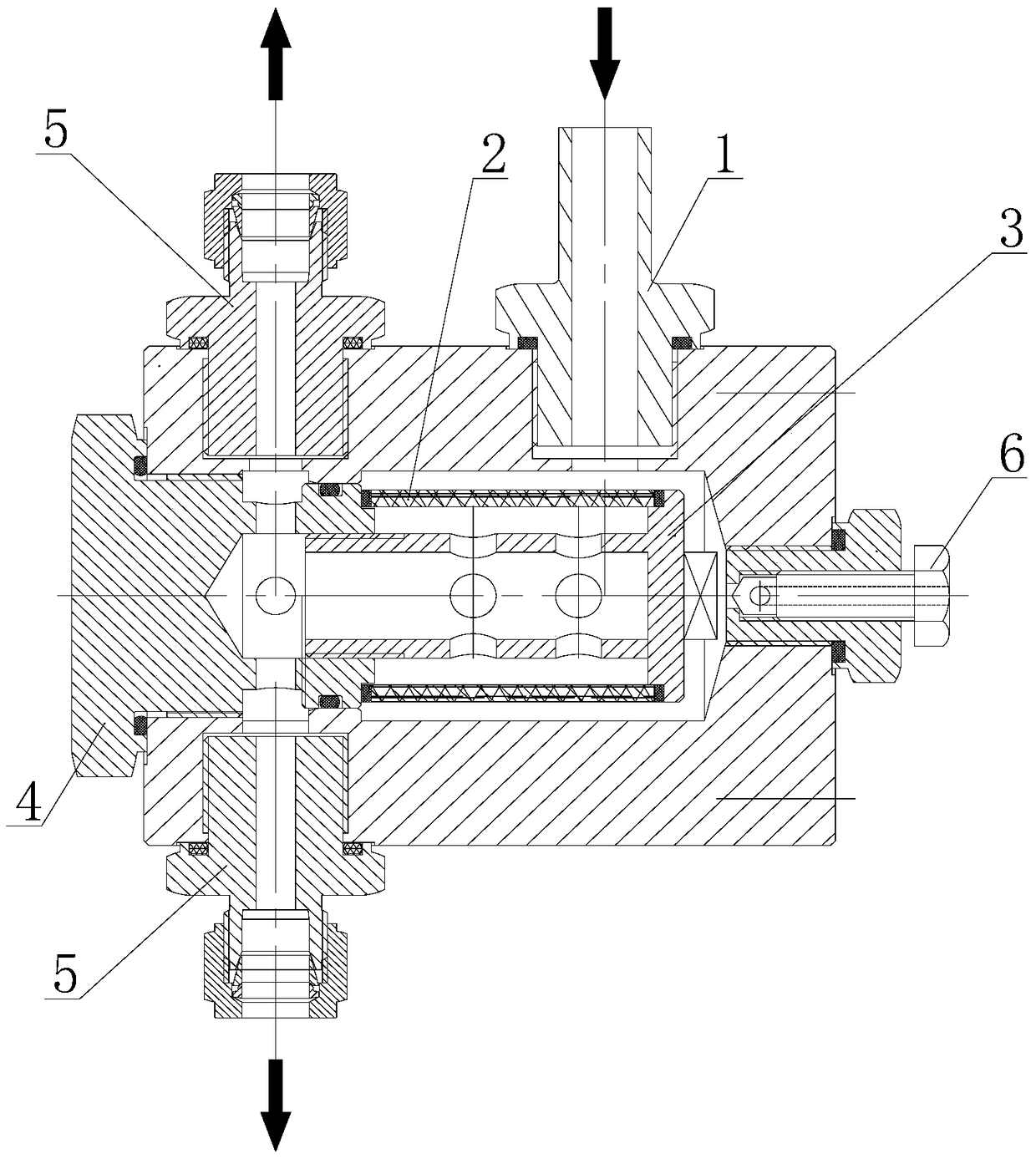

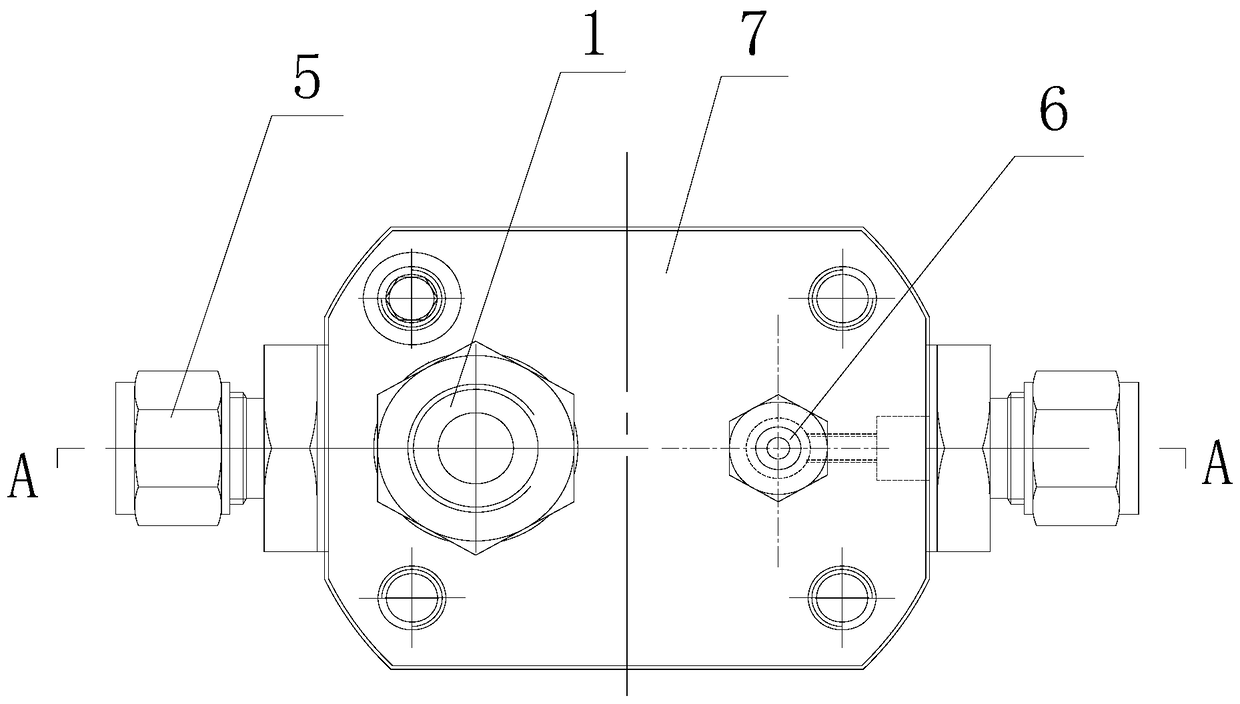

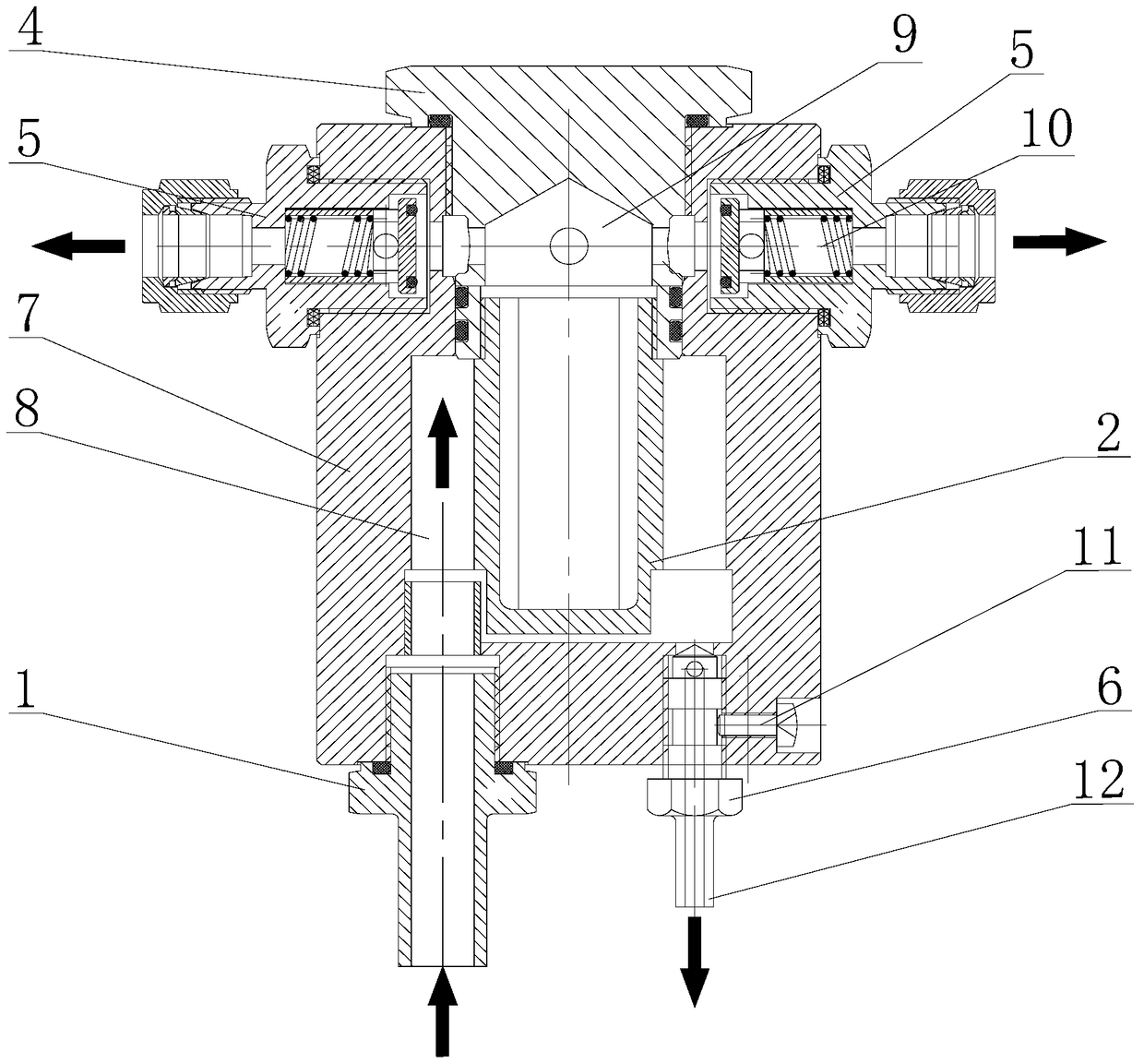

[0031] A kind of multifunctional high-pressure gas safety purifier of present embodiment, as figure 2 or image 3 As shown, it includes a purifier body 7, an upper cover 4, a filter screen 2, an inlet joint 1, an outlet joint 5 and a purge valve 6. The filter screen is arranged in the middle of the purifier body, and the upper cover is arranged on the top of the purifier body. The valve and the inlet joint are respectively arranged at the bottom of the purifier body, and the upper outer wall of the purifier body is provided with two outlet joints; image 3 As shown, the filter screen has a cup-shaped structure, an air intake channel 8 is formed between the outer wall of the filter screen and the inner wall of the purifier body, the inlet joint communicates with the air intake channel, the outlet of the inlet joint is located outside the side wall of the filter screen, and the air intake direction parallel to the side walls of the strainer. In this structure, after the high-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com