Undercarriage buffer

A technology of landing gear buffers and buffers, applied in the field of aeronautical engineering, can solve the problems of complex structure of landing gear buffers and lack of small aircraft landing gear buffers, etc., and achieve the effect of simple structure, reliable performance and strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

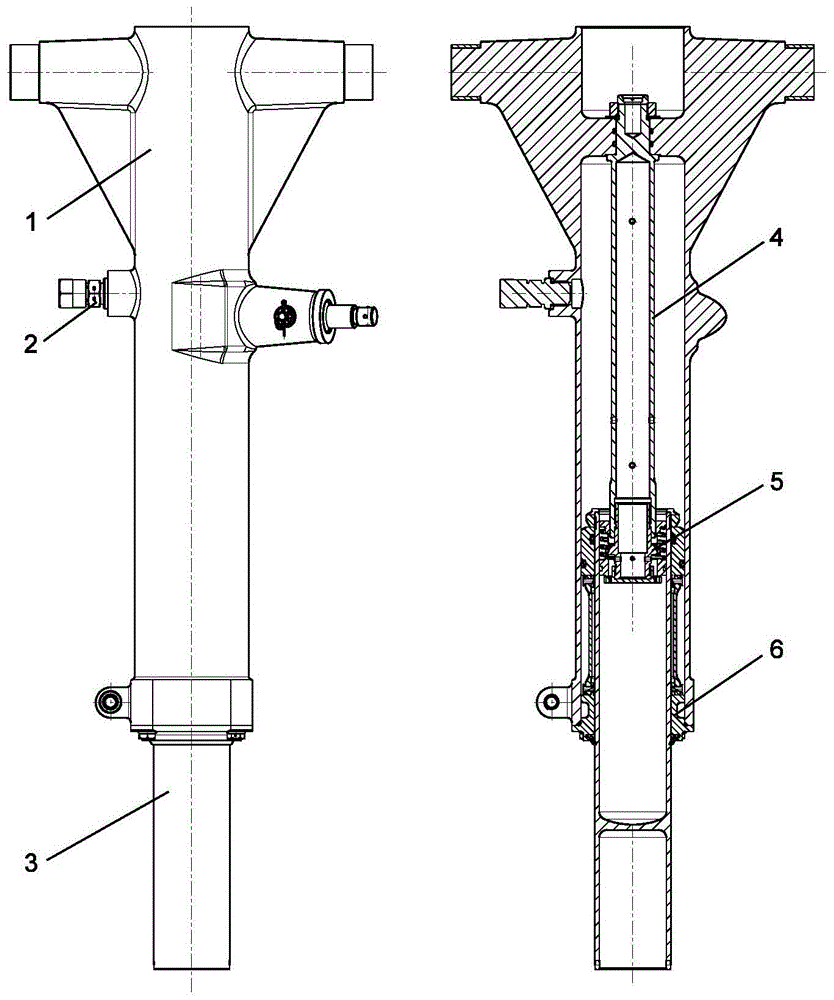

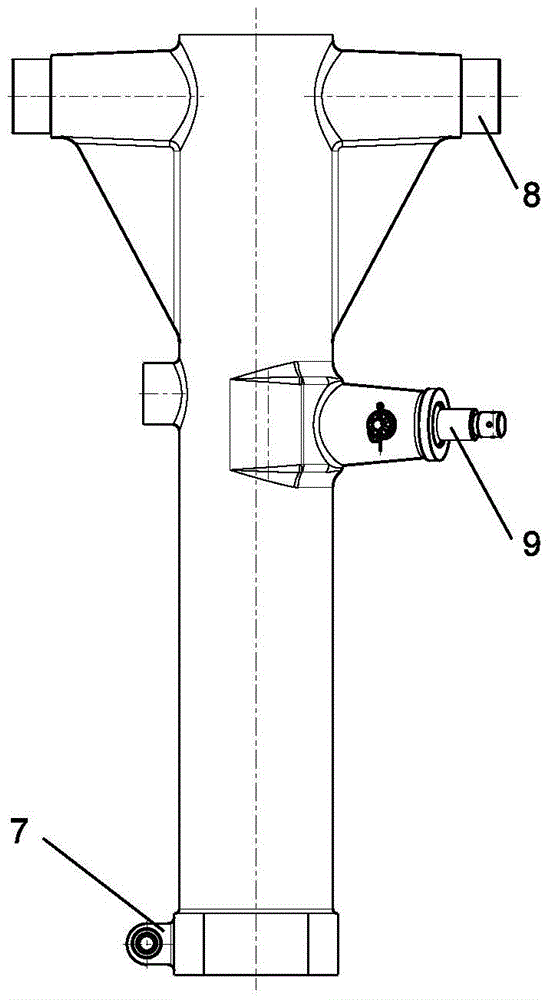

[0022] The installation and working methods of the present invention will be described below in conjunction with the accompanying drawings.

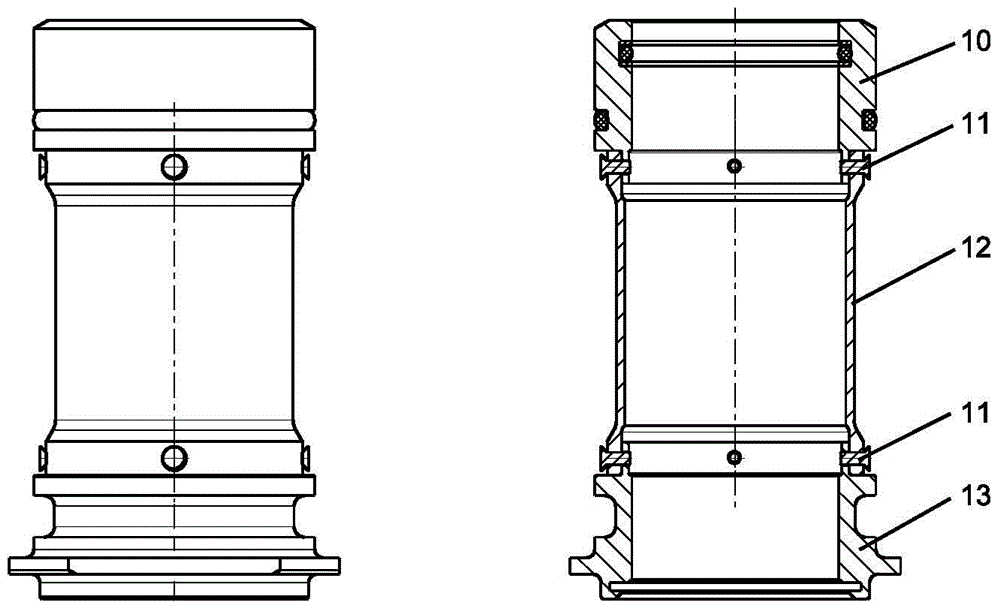

[0023] The filling medium of the buffer is aviation hydraulic oil and industrial nitrogen. like Figure 4 and Figure 7 As shown, the buffer can be divided into three working chambers: chamber A, chamber B and chamber C, wherein chamber A and chamber B communicate through the hole on the oil needle 4 . C chamber is hydraulic oil, the upper part of A chamber and B chamber is nitrogen gas, and the lower part is hydraulic oil.

[0024] The work of the buffer is divided into two cases: forward stroke and reverse stroke.

[0025] When the positive stroke works, the landing gear is affected by the ground reaction force, and the buffer inner cylinder 3 moves upward along the support ring 6. At this time, the volume of the C chamber decreases, and the valve 16 moves upward against the elastic force of the return spring 18 under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com