Feature extraction method based on single-channel signal blind-separation rolling bearing

A rolling bearing and feature extraction technology, which is applied in the field of feature extraction based on single-channel signal blind separation of rolling bearings, can solve problems such as poor immediacy, very different wavelet-based separation effects, and long calculation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

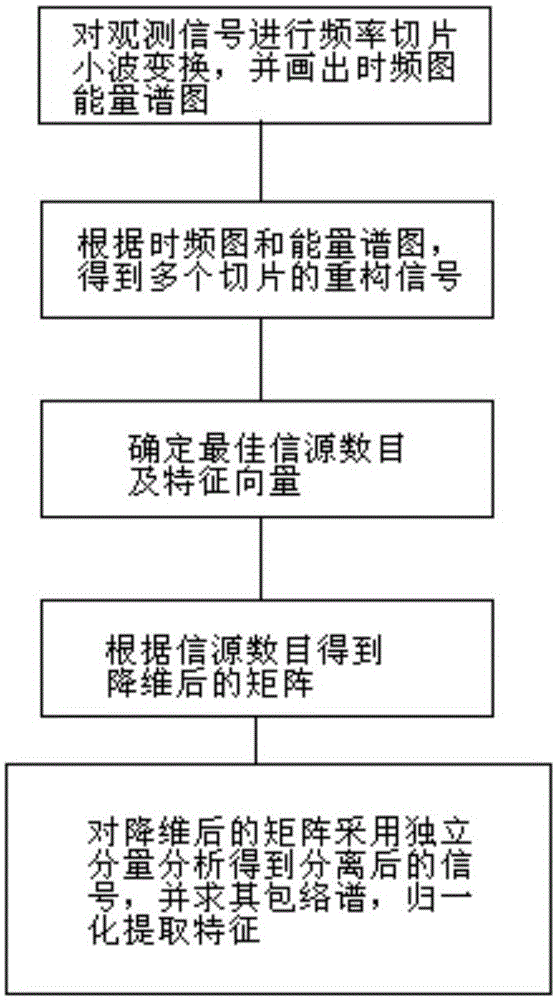

[0069] The feature extraction method of the rolling bearing based on single-channel signal blind separation in this embodiment specifically includes the following steps:

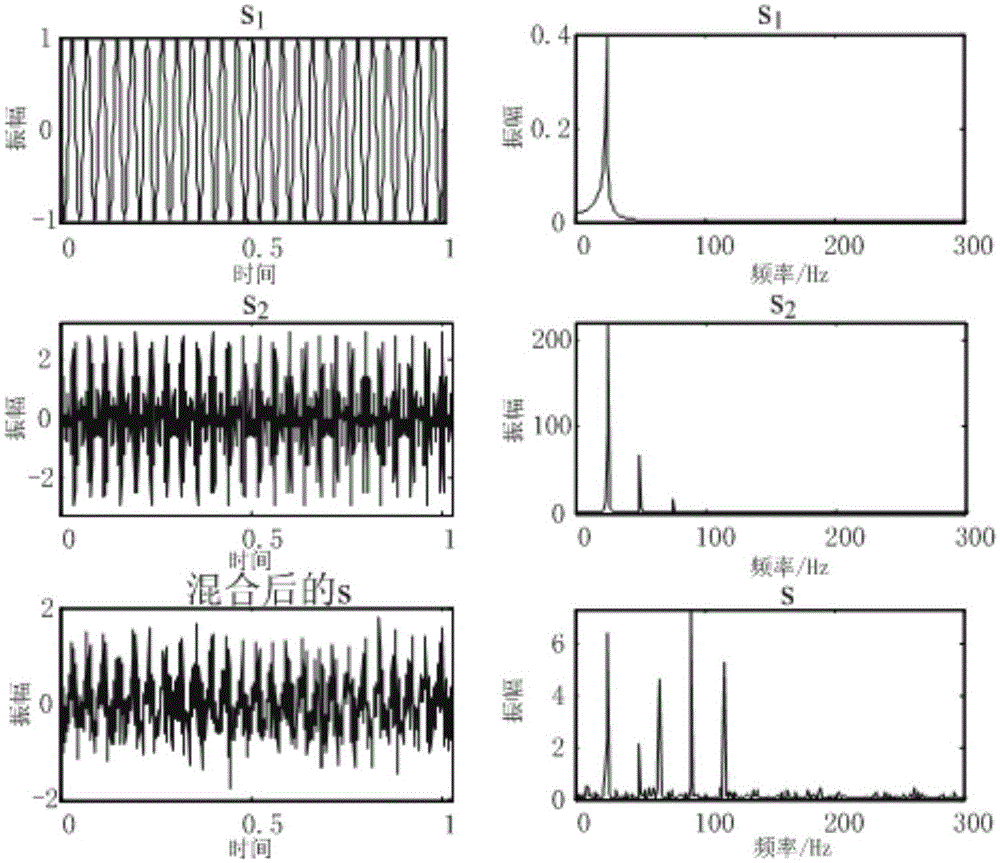

[0070] Step 1: Given two original vibration signals s 1 and s 2 , respectively:

[0071] the s 1 =cos(2πf 1 t+π / 3)

[0072] the s 2 =cos(2πf b t)[1+βcos(2πf r t)]

[0073] Among them, f 1 = 25Hz, f r = 25Hz, f b =115Hz, β=2, the number of sampling points is 1024, the sampling frequency fs is 1000Hz, and the mixed signal model s=as 1 (t)+bs 2 (t)+n(t), wherein, a=1, b=1, n(t) is a random white noise signal. Simulation signal s 1 , s 2 and the time-domain and spectrogram of s, such as figure 2 shown.

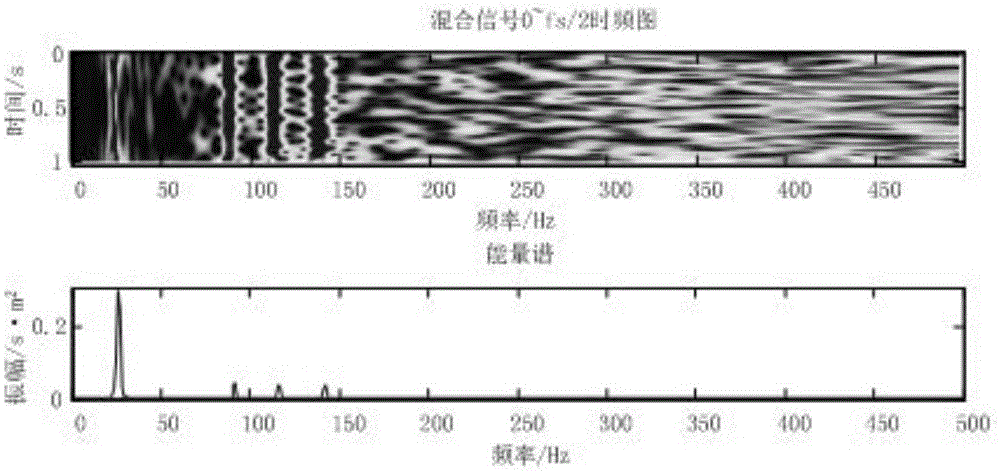

[0074] Select the frequency slicing function, and then perform frequency slicing wavelet transform on the above mixed signal s to obtain its time-frequency diagram in the 0-fs / 2 frequency band, then inverse transform the signal after frequency slicing wavelet transform to obtain the reconstruct...

Embodiment 2

[0092] The method of the invention is used to perform blind separation on a mechanical bearing fault signal, and extract the fault characteristic frequency. The bearing fault is damage to a bearing rolling body. A vibration sensor is installed at the driving end of the bearing, and the sampling frequency fs is 12K Hz. The equipment is loaded with a 1HP load, and its rotational speed is 1777r / min, that is, its fundamental frequency is 29.6Hz. The characteristic frequency of the rolling element fault is calculated according to the characteristic frequency coefficient of its components is 118.1Hz. When the bearing is running, the bearing balls interact with the inner ring and the outer ring, and the source signal has a certain correlation.

[0093] Step 1: Measure the single-channel observation signal through the sensor, and its time-domain waveform diagram is as follows Figure 8 shown.

[0094] Select the frequency slicing function, and then perform frequency slicing wavelet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com