Waveguide magnetic field/current sensor based on surface plasmons and device

A surface plasmon, current sensor technology, applied in the size/direction of the magnetic field, measuring device, measuring current/voltage, etc., can solve the problem of not being able to apply experimental chips, not being able to small-scale integration, optical waveguides and optical devices The classical size Large problems such as high detection sensitivity, convenient integration and arraying, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

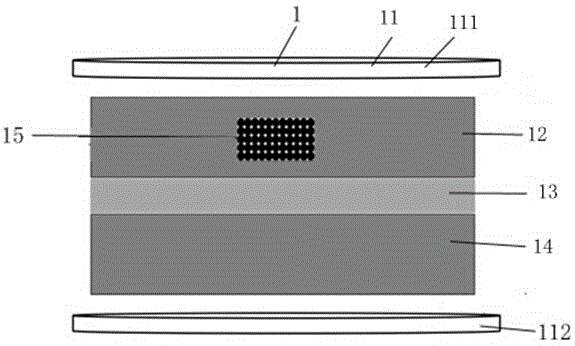

[0029] Such as figure 1 , figure 2 As shown, the surface plasmon-based waveguide magnetic field / current sensor 1 includes a magnetic field generator 11 and a first metal waveguide 12, a dielectric channel 13 and a second The metal waveguide 14, wherein the first metal waveguide 12 and the second metal waveguide 14 are provided with resonant cavities 15; the two resonant cavities 15 pass through the metal slits and dielectrics on the first metal waveguide 12 and the second metal waveguide 14 respectively. The channel 13 is connected, and the resonant cavity 15 is filled with magnetically sensitive substances. The magnetic field generator 11 includes a first pole plate 111 at the top and a second pole plate 112 at the bottom.

[0030] In this embodiment, both the first metal waveguide 12 and the second metal waveguide 14 are silver thin films, the width of the first metal waveguide 12 and the second metal waveguide 14 is 60-160 nm, the first metal waveguide 12 and the second ...

Embodiment 2

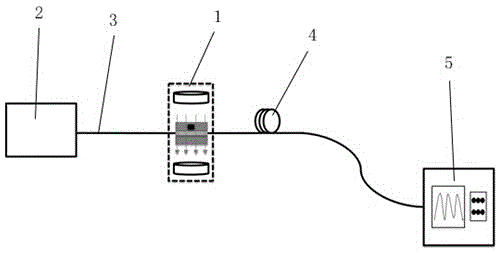

[0047] At the same time, the present invention also provides a device for applying the magnetic field / current sensor 1 described in Embodiment 1, such as figure 2 As shown, it includes a broadband light source 2, a first optical fiber link 3, a magnetic field / current sensor 1, a second optical fiber link 4 and a spectrometer 5, wherein the broadband light source 2 is connected to the input of the magnetic field / current sensor 1 through the first optical fiber link 3 The output end of the magnetic field / current sensor 1 is connected to the spectrometer 5 through the second optical fiber link 4. The broadband light source 2 is used to emit excitation light, that is, the light to be detected. The wavelength range of the excitation light is from visible red to near infrared, and the spectrometer 5 is used to observe the resonant wavelength of the transmission spectrum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com