Ultra-light halogen-free low-smoke flame-retardation ship cable

A low-smoke, flame-retardant, ultra-light technology, applied in the direction of insulated cables, flexible cables, cables, etc., can solve the problems of cable damage, poor corrosion resistance, low melting point of aluminum alloy, etc., to achieve weight reduction and good corrosion resistance , high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

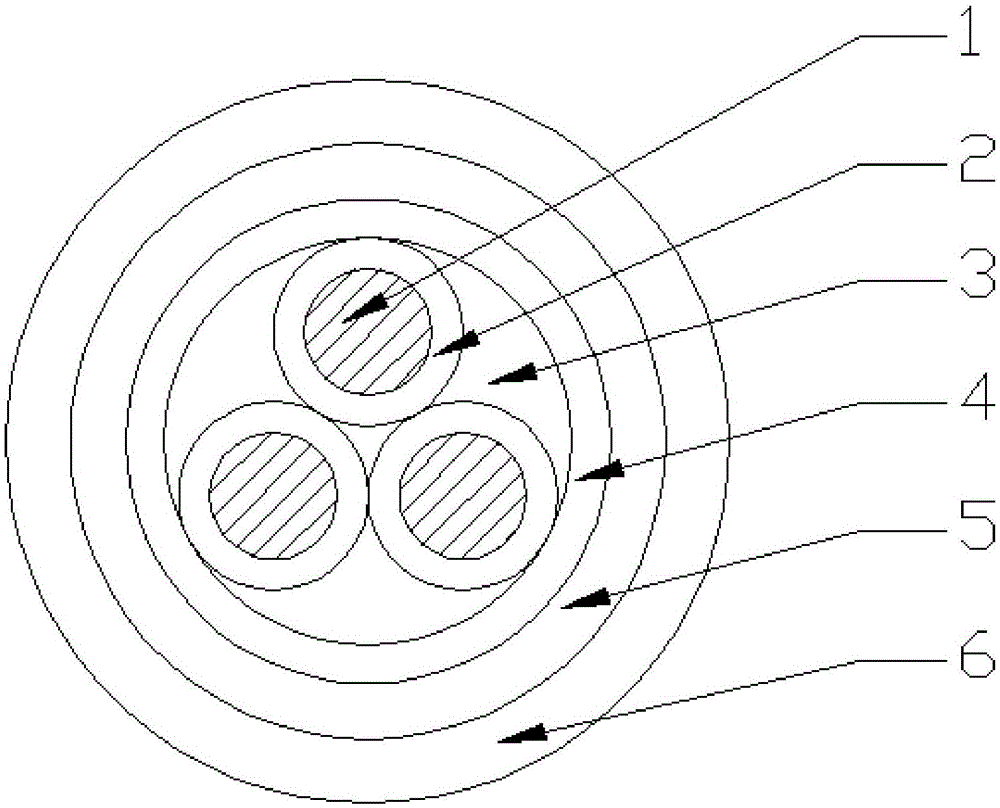

[0028] Such as figure 1 As shown, an ultra-light halogen-free low-smoke flame-retardant ship cable includes a conductor 1, an insulating layer 2, a filling layer 3, a wrapping layer 4, a braided armor layer 5 and a sheath layer 6, and the insulating layer 2 Extruded on the conductor 1 to form a wire core, several wire cores are twisted with each other to form a cable core, the wrapping layer 4 is set on the cable core, and a braided armor layer is braided on the outer surface of the wrapping layer 4 5. The sheath layer 6 is set on the braided armor layer 5;

[0029] The conductor 1 adopts tinned oxygen-free copper type 2 stranded flexible conductor. On the premise of ensuring the standard resistance, the diameter of the single wire is reduced to reduce the weight of the cable conductor. During the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com