Automatic conversion device of alternating current power supply

An automatic conversion, AC power supply technology, applied in the output power conversion device, high-efficiency power electronic conversion, AC power input conversion to AC power output and other directions, can solve the problem of poor output voltage stability, power grid harmonic pollution, environmental electromagnetic pollution, etc. problems, to achieve the effect of low voltage regulation rate, overload protection and short circuit protection, and wide input range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

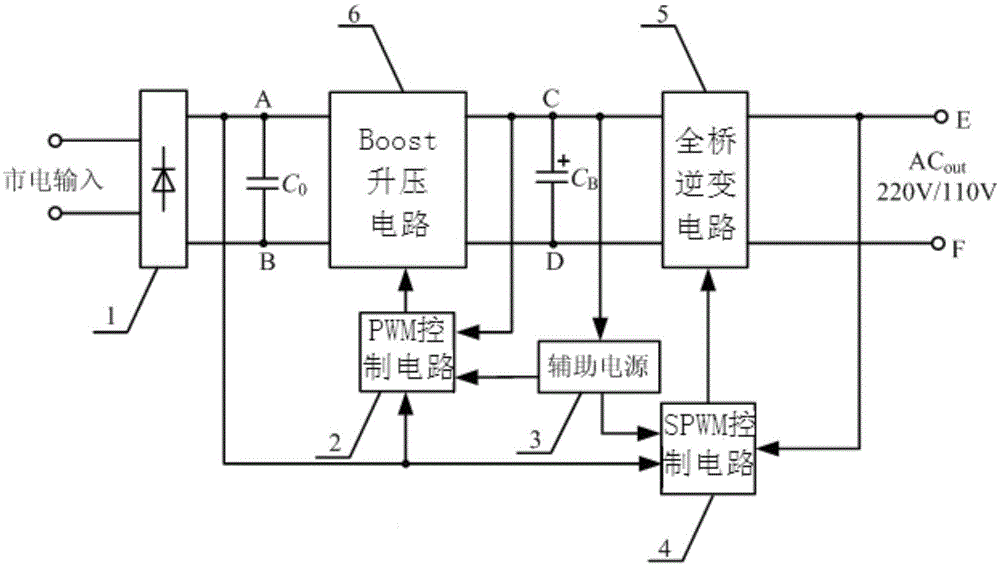

[0019] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the AC power automatic conversion device described in this embodiment includes two-stage circuits, the front stage is a Boost circuit with APFC function; the latter stage is a full-bridge inverter that can automatically switch the output according to the input voltage level The circuit specifically includes a diode bridge rectifier circuit 1, a PWM control circuit 2, an auxiliary power supply 3, an SPWM control circuit 4, a full-bridge inverter circuit 5 and a Boost circuit 6;

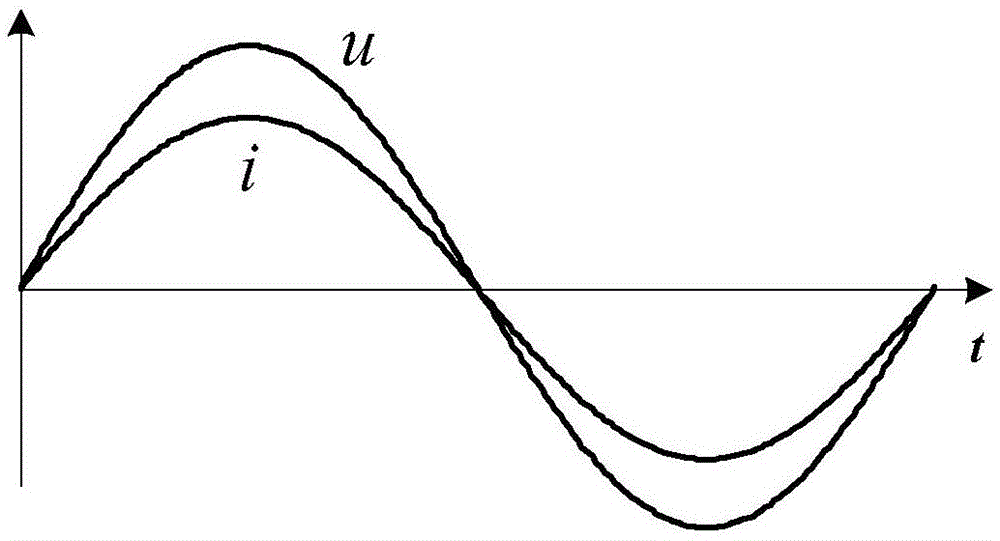

[0020] The mains input is rectified by the diode bridge rectifier circuit 1 and then output. The two input terminals of the boost circuit 6 are respectively connected to the output terminal A and the output terminal B of the diode bridge rectifier circuit 1, and the output terminal A of the diode bridge rectifier circuit 1 A filter capacitor C is connected in parallel with the output terminal B 0 , th...

specific Embodiment approach 2

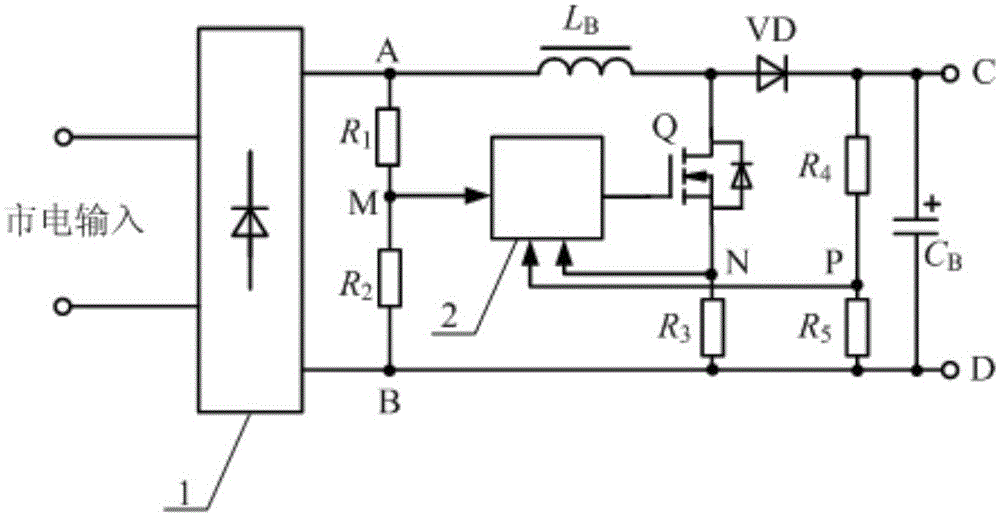

[0025] Specific implementation mode two: the following combination Figure 2-Figure 4 Describe this embodiment, this embodiment will further illustrate Embodiment 1, and the Boost voltage boosting circuit 6 includes a resistor R 1 , resistance R 2 , inductance L B , switch tube Q, resistor R 3 , diode VD, resistor R 4 and resistor R 5 ;

[0026] Resistance R 1 One end of the diode bridge rectifier circuit 1 is connected to the output terminal A, and the resistance R 2 One end of the diode bridge rectifier circuit 1 is connected to the output terminal B, and the resistance R 1 the other end and the resistor R 2 The other end of is connected to sampling point M;

[0027] Inductance L B One end of the diode bridge rectifier circuit 1 is connected to the output terminal A, and the inductor L B The other end is connected to the drain of the switch tube Q, and the resistor R 3 One end of the diode bridge rectifier circuit 1 is connected to the output terminal B, and the ...

specific Embodiment approach 3

[0034] Specific implementation mode three: the following combination Figure 5 Describe this embodiment mode, this embodiment mode will further illustrate Embodiment 1, and the full-bridge inverter circuit 5 includes a resistor R S , switch tube Q 1 , switch tube Q 2 , switch tube Q 3 , switch tube Q 4 , inductance L and capacitance C;

[0035] The output terminal C of the boost circuit 6 is connected to the switch tube Q at the same time 1 The drain and switch Q 2 The drain of the boost circuit 6 is connected to the output terminal D of the resistor R S One end of the resistor R S The other end of the switch tube Q 3 source and switch Q 4 The source is connected as the sampling point O at the same time, the switch tube Q 1 source and switch Q 3 The drain connection of the node G, the switch Q 2 source and switch Q 4 The drain of the inductor L is connected to the output terminal F, one end of the inductor L is connected to the node G, the other end of the inducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com