A wood play roller paint device with drying function

A paint rolling and functional technology, applied in the field of parts painting, can solve problems such as unsatisfactory pollution control effect, difficulty in grasping the quality of painting, and pollution of the workshop environment, so as to improve work efficiency and product quality, reduce drying energy consumption, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

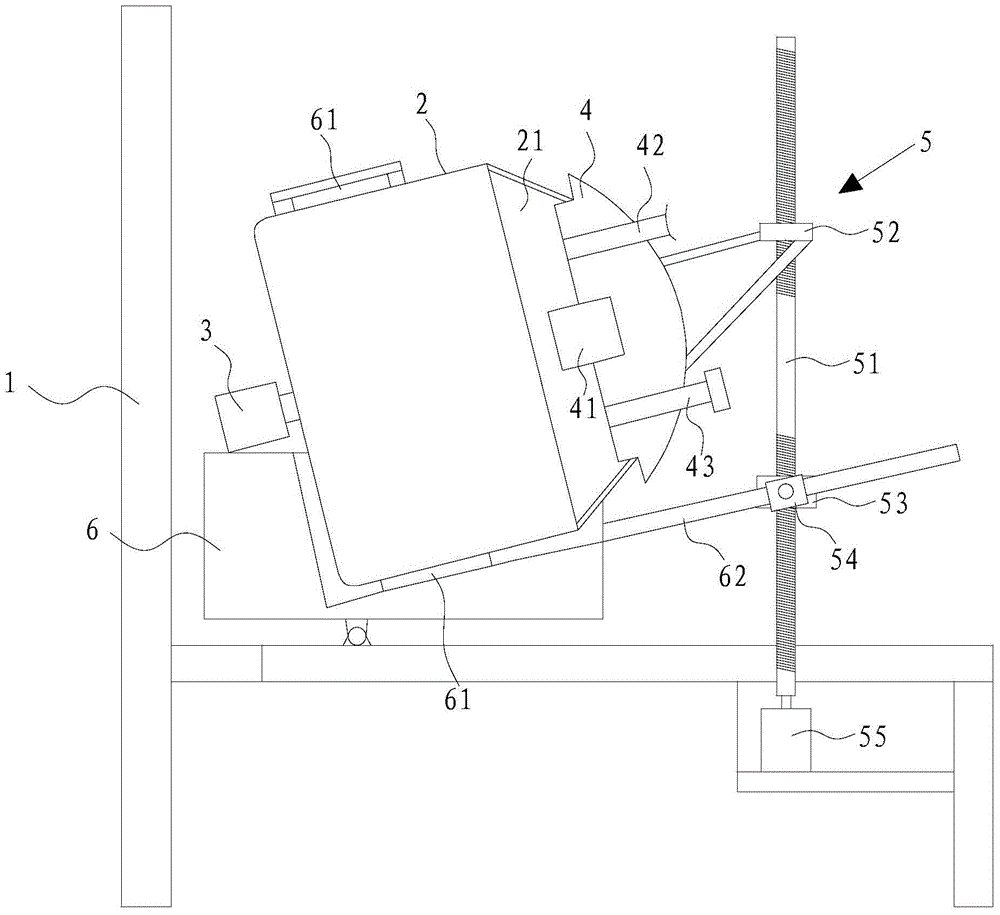

[0024] Such as figure 1 As shown, the wood play paint roller device with drying function of the present embodiment includes: a frame 1, a paint roller 2 installed on the frame 1, a variable speed motor 3 for driving the paint roller 2 to rotate, a sealing cover 4 and Open and close the lift mechanism 5 of the sealing cover 4 .

[0025] The paint roller 2 is arranged obliquely and the inclination angle is adjustable. The upper surface of the paint roller 2 is provided with an opening 21, and the sealing cover 4 and the opening 21 are rotated and sealed. In this embodiment, the sealing cover 4 and the opening 21 are non-contact seals. The distance between the sealing cover 4 and the edge of the opening 21 is 5 mm.

[0026] The inboard of sealing cover 4 is fixed with the ceramic infrared heater 41 that is used for drying wooden play surface spray paint, and the sealing cover is provided with the air outlet 42 that is used to connect exhaust fan and the inlet 43 of paint sprayin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com