A kind of environment-friendly high-strength adhesive for cracks in buildings and preparation method thereof

An environmentally friendly, adhesive technology, applied in the field of adhesives, can solve the problems of environmentally friendly high-strength adhesives that have not been reported in the literature, and achieve the effects of ensuring good health, good impermeability, and high irrigability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1. Components and mass percentage

[0012] Water-based epoxy emulsion 69%, triallylamine water-based curing agent 19%, superfine cement (DMFC-GM) 6%, dioctyl phthalate (DOP) 0.17%, KS25 fungicide 0.10%, tap water 5.73 %.

[0013] 2. Preparation method

[0014] 1. Put the water-based epoxy emulsion and dioctyl phthalate (DOP) in the container first, and use a GST-20LB portable mixer with a motor power of 0.1Kw and a speed of 1200r / min to stir for 20 minutes evenly.

[0015] 2. Put the ultra-fine cement (DMFC-GM) into the bucket, then add all the tap water into the bucket, and stir for 15 minutes to make it even. Add the diluted cement slurry in the barrel to the above container 1 and stir for 20 minutes to make it even, then add KS25 fungicide and stir for 15 minutes to make it even.

[0016] 3. Then add the triallylamine water-based curing agent, stir for 20 minutes to evenly mature and use it. After two hours are used up, it is ready to use now.

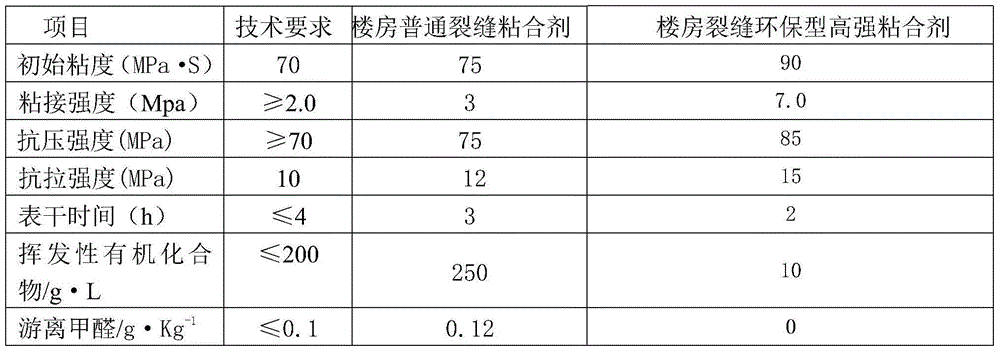

[0017] 3. The be...

Embodiment 2

[0020] 1. Components and mass percentage

[0021] Water-based epoxy emulsion 70%, triallylamine water-based curing agent 20%, superfine cement (DMFC-GM) 5%, dioctyl phthalate (DOP) 0.18%, KS25 fungicide 0.12%, tap water 4.7 %.

[0022] 2. Preparation method

[0023] 1. First put the water-based epoxy emulsion and dioctyl phthalate (DOP) in a container, use a GST-20LB portable mixer with a motor power of 0.1Kw, a speed of 1200r / min, and stir for 19 minutes to make it even.

[0024] 2. Put the ultra-fine cement (DMFC-GM) into the bucket, then add all the tap water into the bucket, and stir for 14 minutes to make it even. Add the diluted cement slurry in the barrel to the above container 1 and stir for 19 minutes to make it even, then add KS25 fungicide and stir for 14 minutes to make it even.

[0025] 3. Then add the triallylamine water-based curing agent, stir for 19 minutes to evenly mature and use it. After two hours are used up, it is ready to use now.

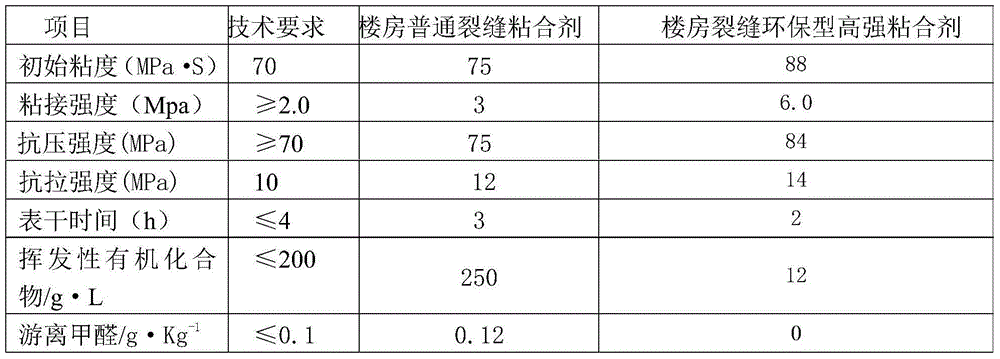

[0026] 3. The b...

Embodiment 3

[0029] 1. Components and mass percentage

[0030] Water-based epoxy emulsion 71%, triallylamine water-based curing agent 21%, superfine cement (DMFC-GM) 4%, dioctyl phthalate (DOP) 0.15%, KS25 fungicide 0.15%, tap water 3.7 %.

[0031] 2. Preparation method

[0032] 1. First put the water-based epoxy emulsion and dioctyl phthalate (DOP) in a container, use a GST-20LB portable mixer with a motor power of 0.1Kw, a speed of 1200r / min, and stir for 21 minutes to make it even.

[0033] 2. Put the ultra-fine cement (DMFC-GM) into the bucket, then add all the tap water into the bucket, and stir for 16 minutes to make it even. Add the diluted cement slurry in the barrel to the above container 1 and stir for 21 minutes to make it even, then add KS25 fungicide and stir for 16 minutes to make it even.

[0034] 3. Then add the triallylamine water-based curing agent, stir for 21 minutes to evenly mature and use it. After two hours are used up, it is ready to use now.

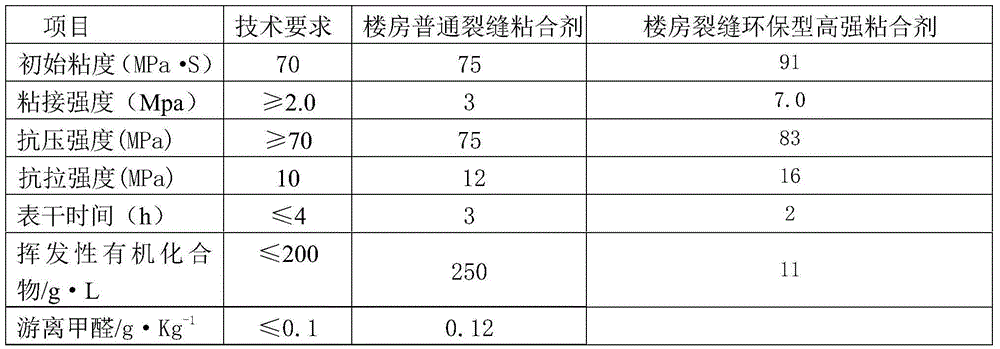

[0035] 3. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com