Unmanned-plane-based high-altitude welding and cutting method

A cutting method and UAV technology, applied in welding equipment, aluminothermic welding equipment, metal processing equipment, etc., can solve the problems that it is difficult for work or rescue personnel to approach the work area in time, it is difficult to transport equipment, and the staff is in danger. , to achieve the effect of improving welding/cutting efficiency, wide application range and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

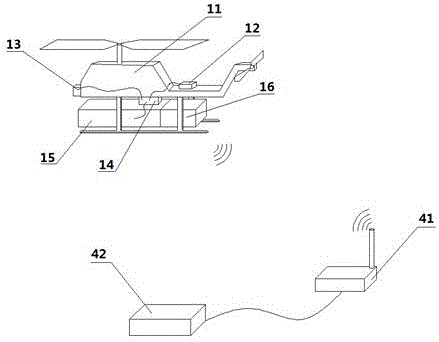

[0043] The basic idea of the present invention is to combine self-propagating combustion reaction welding and cutting with unmanned aerial vehicles to safely and efficiently perform welding or cutting in various occasions where manual operation is impossible or unfavorable.

[0044] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

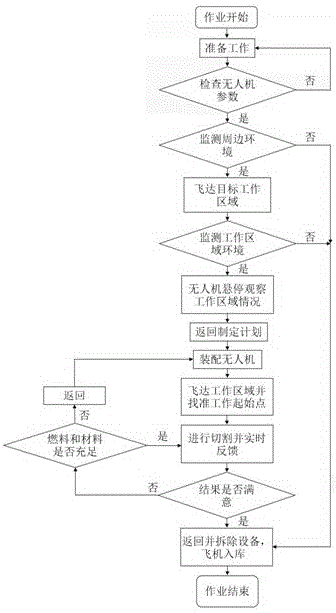

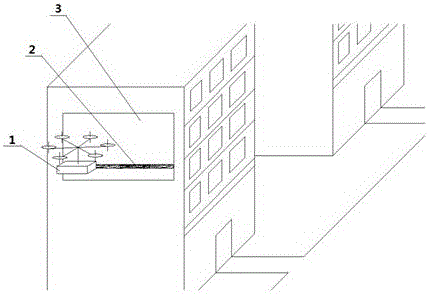

[0045] Specifically, such as figure 2 The operation process of applying the self-propagating reaction-based UAV welding and cutting method to the area to be welded on the outer wall of a building at a height of 25m is as follows:

[0046]Select the Servoheli-120 UAV from Shenyang Institute of Automation and check that the battery is fully charged. The motor, sensor and detector ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com