Flexible unit and flexible wrist for industrial robot precision assembly

An industrial robot and flexible technology, applied in the field of mechanical wrists, can solve the problems of tearing, high processing cost, complex processing, etc., and achieve the effects of reducing processing and manufacturing costs, simple processing methods, and high service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

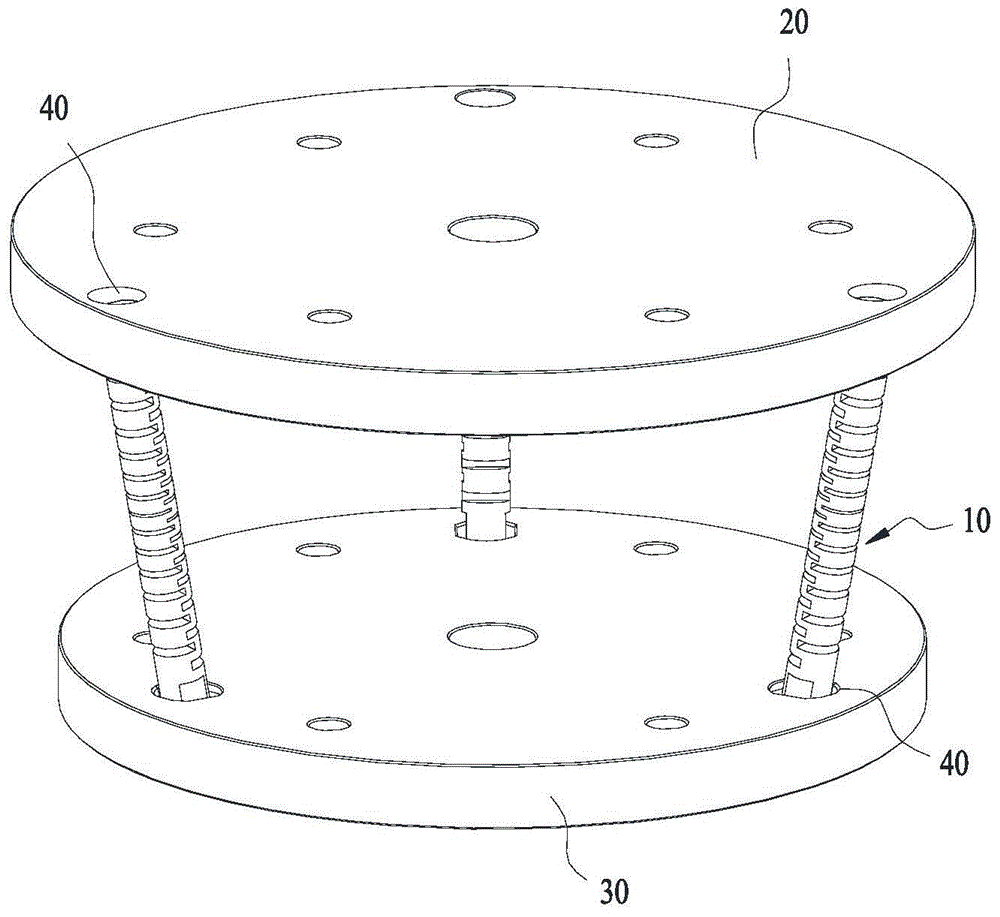

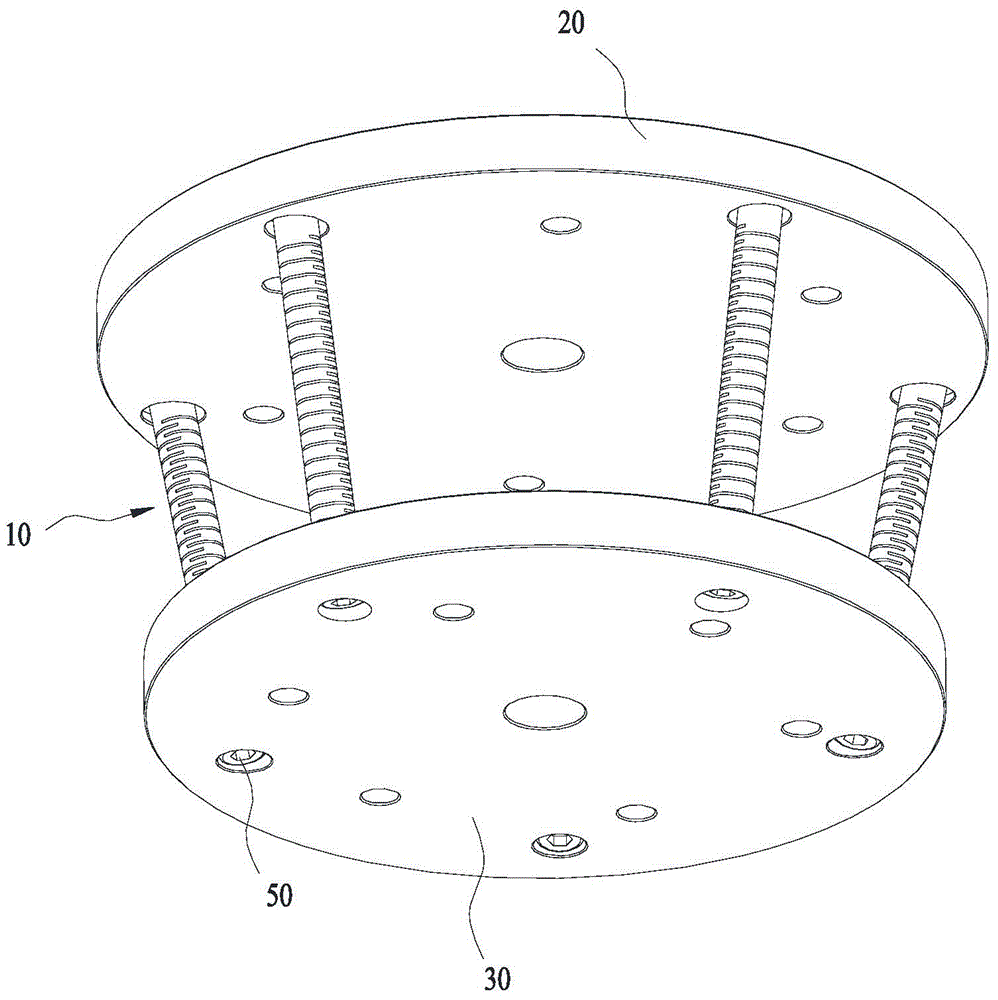

[0034] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

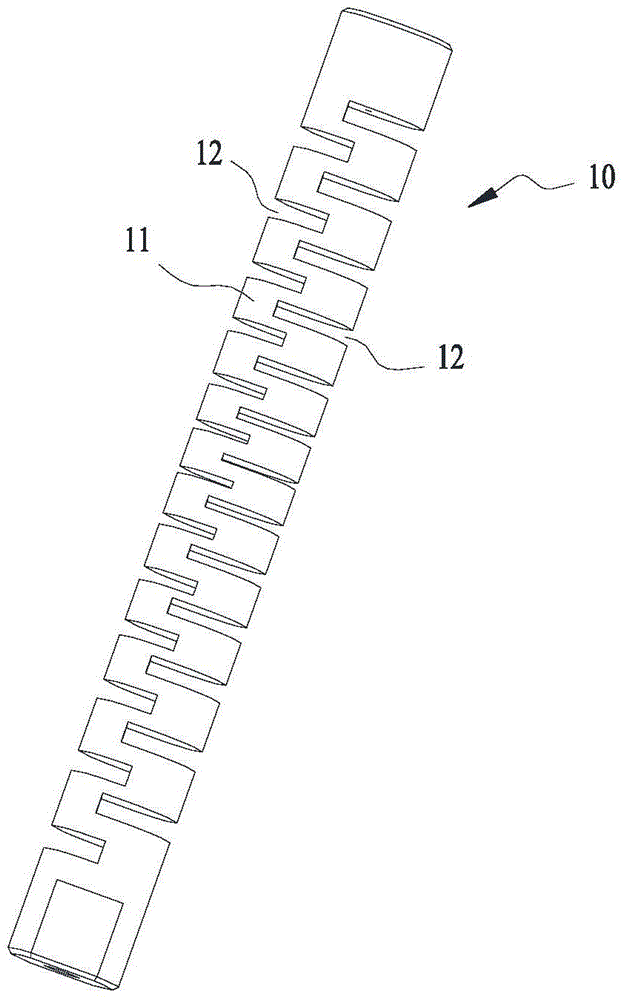

[0035] like figure 1 The shown flexible unit for precision assembly of industrial robots includes a strip-shaped flexible body 11, and a plurality of slots 12 are opened on the side of the flexible body 11, and each slot 12 is along the length direction of the flexible body 11. interval distribution.

[0036] The flexible body 11 can be made of metal material, and the number of slots 12 and the extending directions of the slots 12 can be set correspondingly according to the design requirements of flexibility. In order to make the flexible unit 10 have uniform flexibility in all directions, the following settings can be made in this example:

[0037] The slots 12 are alternately distributed on opposite sides of the flexible body 11 . The distances between adjacent slots 12 are equal, the slot widths of each slot 12 are equal, and the slot depths of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com