corrugated roll

A corrugated paper roll and corrugated technology, applied in the direction of mechanical processing/deformation, can solve the problems of the strength and paper consumption of corrugated cardboard not reaching the best ratio, the uneven surface temperature of the roll body, and the reduction of the service life of the roll body, etc. Achieve the effect of compact structure, high utilization efficiency and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

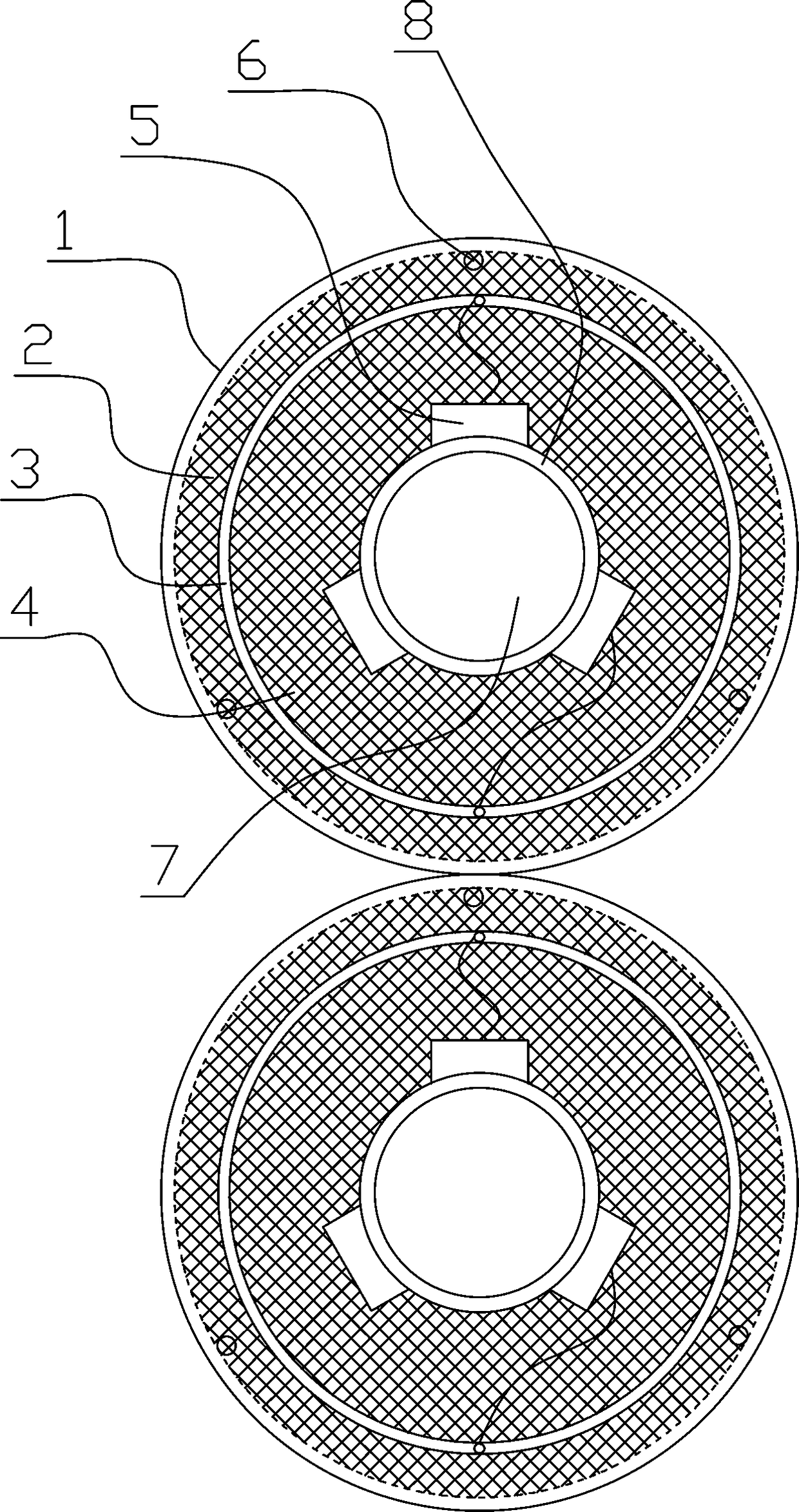

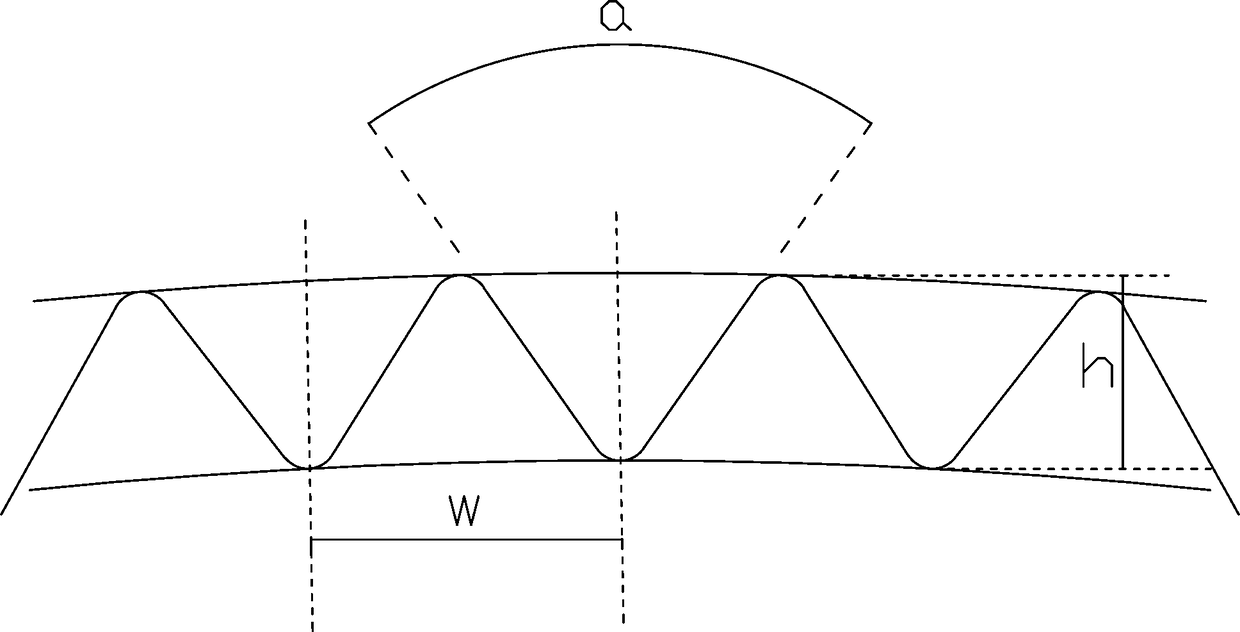

[0022] like figure 1 , 2 Among them, a corrugated paper roll, the roll body 1 is provided with an induction heating device. With this structure, the energy consumption of heating is further reduced, and the temperature of the surface of the roller body is uniform, so as to prolong the service life of the roller body.

[0023] Preferably, a tungsten carbide layer is provided on the surface of the roller body 1 . To increase the strength of the roller teeth on the surface of the roller body 1 .

[0024] The roller body 1 is provided with a first insulation layer 2 , an induction coil 3 and a second insulation layer 4 sequentially from outside to inside. In this example, asbestos and perlite are used for insulation. The thickness of the second insulation layer 4 is greater than the thickness of the first insulation layer 2 . So that the equipment inside the second thermal insulation layer 4 is not affected by high temperature. The induction coil is electrically connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com