Three-way distributor and use method

A technology of three-way feeder and feeder, which is applied in the direction of transportation and packaging, slideway, etc., to achieve the effect of protecting human health, strong thinking, and strong corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

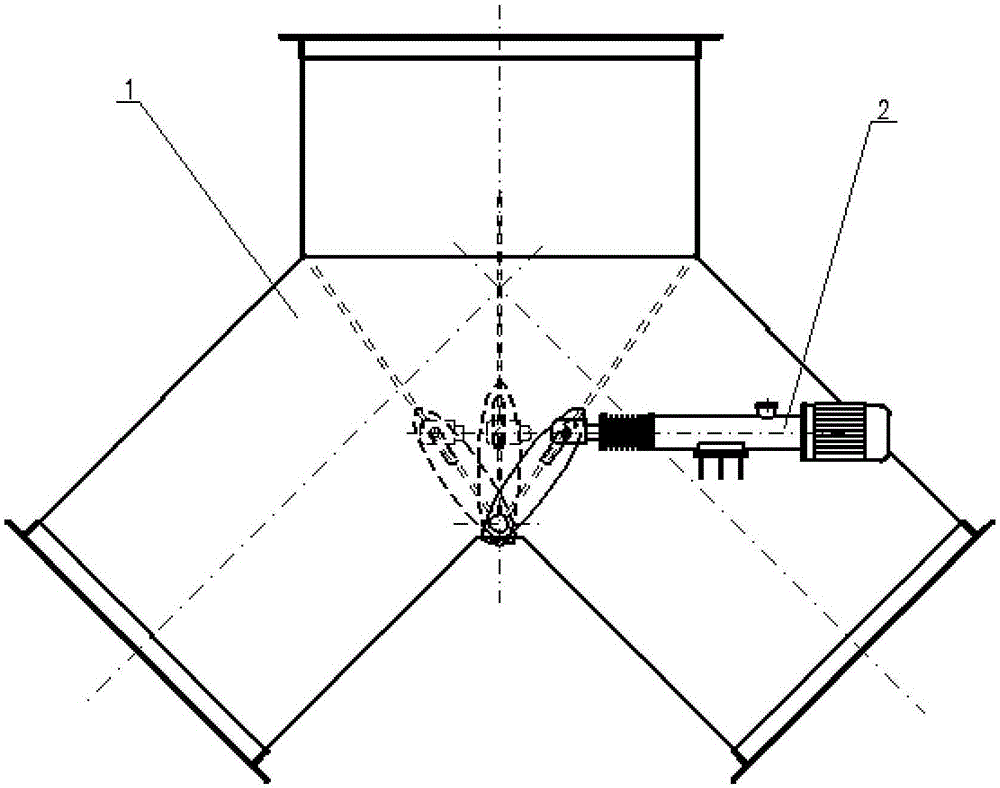

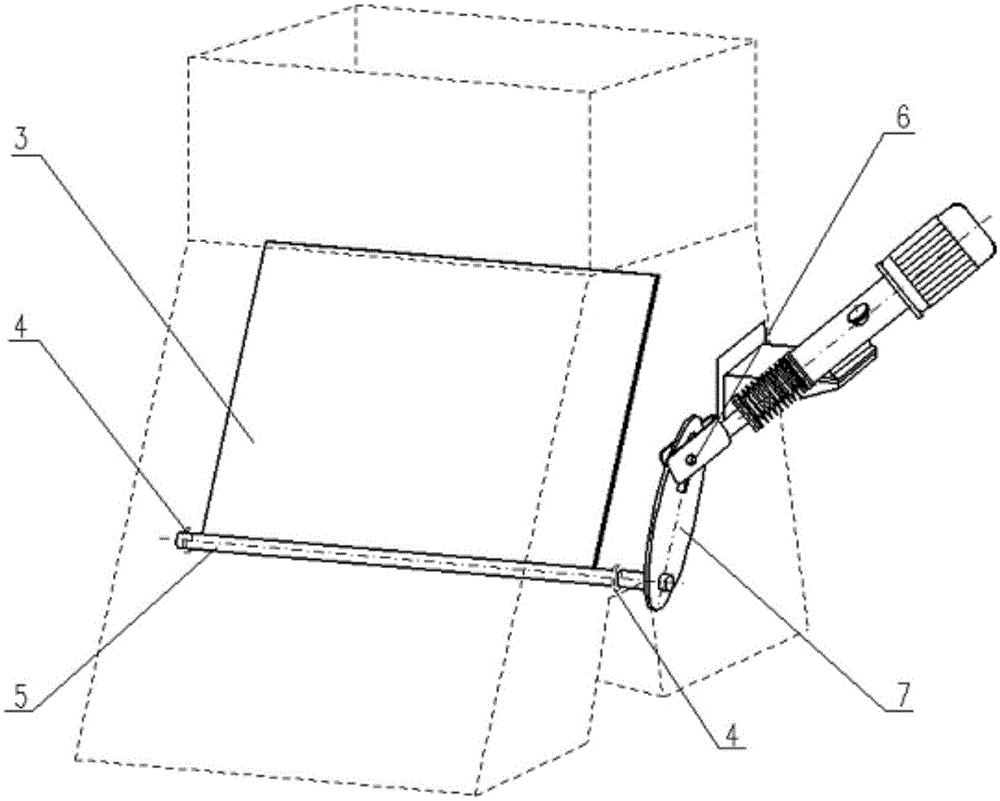

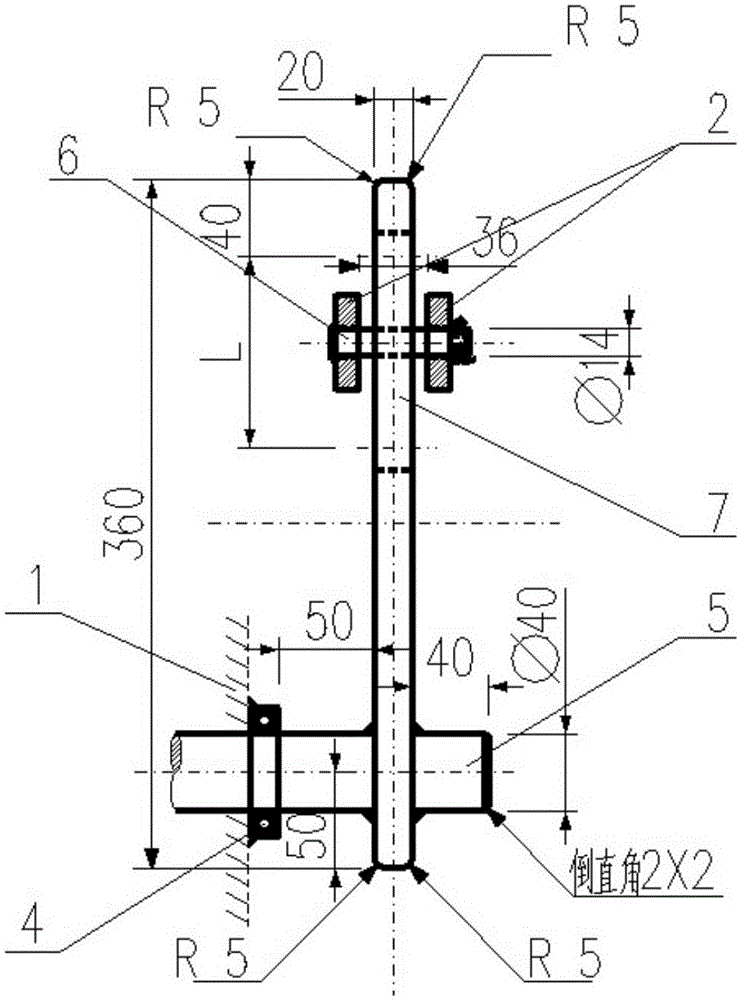

[0025] Figure 1-Figure 4 It is a specific embodiment of the present invention.

[0026] A three-way distributor, including a three-way chute 1, an electro-hydraulic push rod 2, a flap 3, a single-sided deep groove ball bearing with a sealing ring 4, a rotating shaft 5, a pin shaft 6 and a special guide rod 7; the three-way There are two through holes at the bottom of the bifurcation of the chute 1, and the two ends of the rotating shaft 5 are equipped with a single-sided deep groove ball bearing 4 with a sealing ring, and the outer steel ring of the single-sided deep groove ball bearing 4 with a sealing ring is welded on the through hole. The plate 3 is welded on the rotating shaft 5; one end of the rotating shaft 5 is welded to the special guide rod 7, the electro-hydraulic push rod 2 is connected to the special guide rod 7 through the pin shaft 6, and the special guide rod 7 is an oblong stainless steel sheet with an oblong opening in the middle hole. The ellipse size is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com