Vertical lifting system of double-winding permanent magnet fault tolerance motor and control method of vertical lifting system

A permanent magnet fault-tolerant, vertical lifting technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve problems such as complex analytical formula, complex control algorithm, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

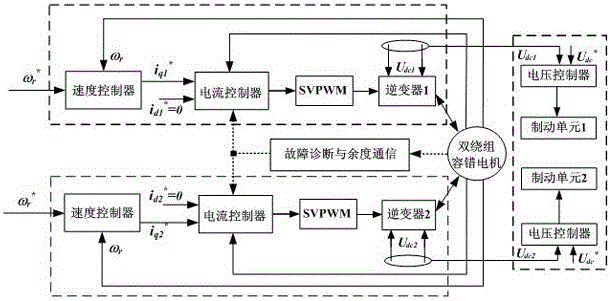

[0068] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

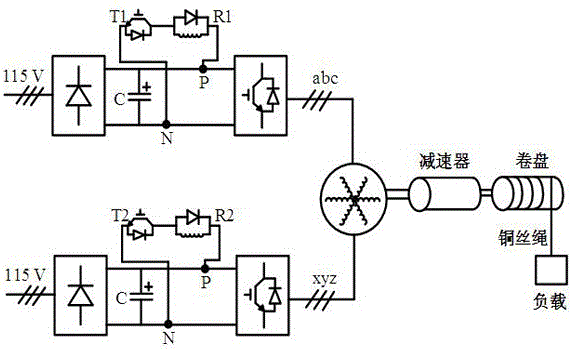

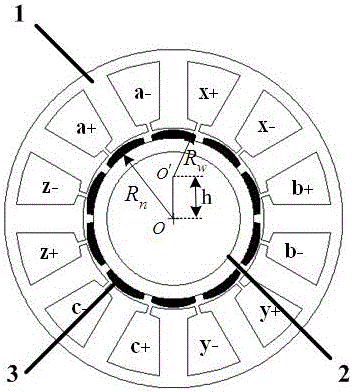

[0069] Such as figure 1 As shown, the present invention discloses a vertical lifting system for a double-winding permanent magnet fault-tolerant motor, which includes first to second rectification circuits, first to second braking circuits, first to second three-phase full-bridge drive circuits, Double-winding permanent magnet fault-tolerant motor, reducer, reel, copper wire rope and load mechanism;

[0070] The first rectifier circuit, the first brake circuit, and the first three-phase full-bridge drive circuit are connected in sequence;

[0071] The second rectification circuit, the second brake circuit, and the second three-phase full-bridge drive circuit are connected in sequence;

[0072] Both the first three-phase full-bridge drive circuit and the second three-phase full-bridge drive circuit are connected to the double-winding permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com