Cohesive soil curing agent and cohesive soil soft foundation treating method thereof

A cohesive soil and curing agent technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of poor reinforcement effect of cohesive soil, and meet the requirements of engineering construction and high compressive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Sampling of undisturbed soil

[0020] Soil samples were taken from Bid Section 8 (K57+000~K62+200) of the two phases of the Cangzhou Qikou-Haifeng section of the coastal expressway. Yellowish brown to taupe, in fluid plastic to soft plastic state, with an average moisture content of 34%, uneven soil quality, smooth cut surface, medium dry strength, medium toughness, containing illite, organic matter and broken shells, and the water quality is weakly alkaline. The pH value is 7.3, and the water chemical type is Cl-Na. The basic allowable value of bearing capacity is 90~130KPa. Soil samples were taken from above the groundwater table.

[0021] 2. Preparation of cohesive soil curing agent

[0022] Weigh 5 kg of steel slag and 5 kg of quicklime respectively, and mix the two evenly to obtain a cohesive soil curing agent for subsequent use.

[0023] The weight percent composition of steel slag used includes TFe34%, SiO 2 16%, MgO6%, CaO42%.

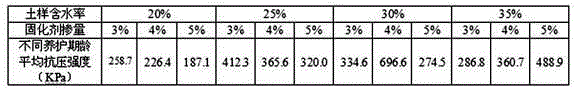

[0024] 3. Compressive st...

Embodiment 2

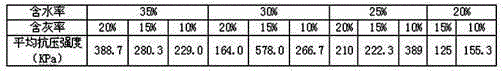

[0046] The weight percent composition of steel slag used in the cohesive soil curing agent includes TFe30%, SiO 2 14%, MgO7%, CaO44%, other with embodiment 1, test result is shown in Table 2.

[0047] Table 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com