Composite plastic tube

A plastic pipe and plastic technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as leakage, accidents, and easy deformation of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

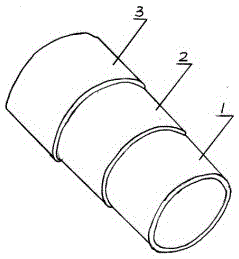

[0011] Such as figure 1 Shown is the pipe wall structure of the composite plastic pipe. The pipe is multi-layered. This embodiment has three layers. The inner pipe 1 is the water transfer layer, the middle layer 2 is the reinforcement layer, and the outermost layer 3 is the wear-resistant layer, which is Composite tubing provides strength support. The outer tube 3 of this embodiment is composed of 100 parts by weight of low-density polyethylene, 10 parts by weight of EVA (ethylene-vinyl acetate copolymer), and 0.3 parts by weight of antioxidant. The middle layer 2 is made of 80 parts by weight of high-density polyethylene, nanometer 10 parts by weight of calcium carbonate, the inner tube 1 is composed of 10 parts by weight of high-density HDPE10096 parts by weight, 5 parts by weight of antibacterial masterbatch, and the antibacterial masterbatch is composed of 3 parts by weight of high-density polyethylene HDPE10093 parts by weight, and 3 parts by weight of antioxidant. Inorg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com